Condensation type gas water heater and constant-temperature control method

A gas water heater, condensing technology, applied in the direction of water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of unresolved water resources, unstable water temperature, inconvenient control, etc., to solve the problem of temperature fluctuations, installation Realize the effect of convenience and simple waterway

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

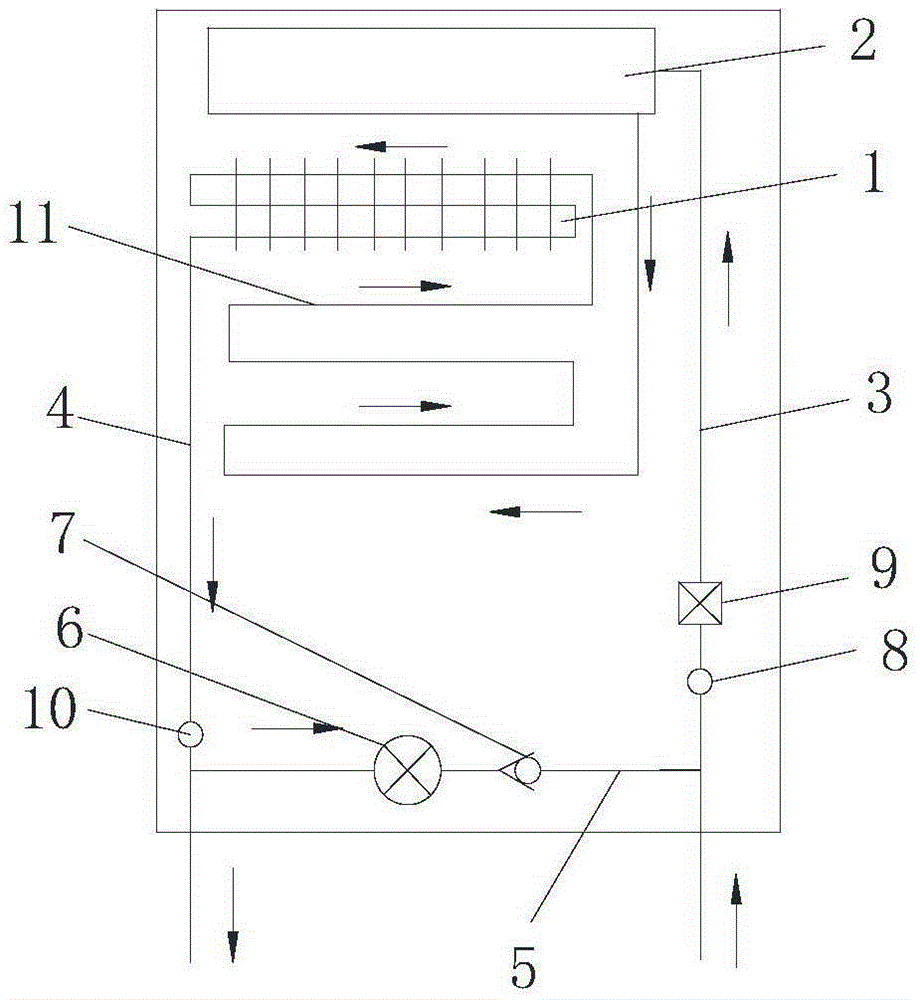

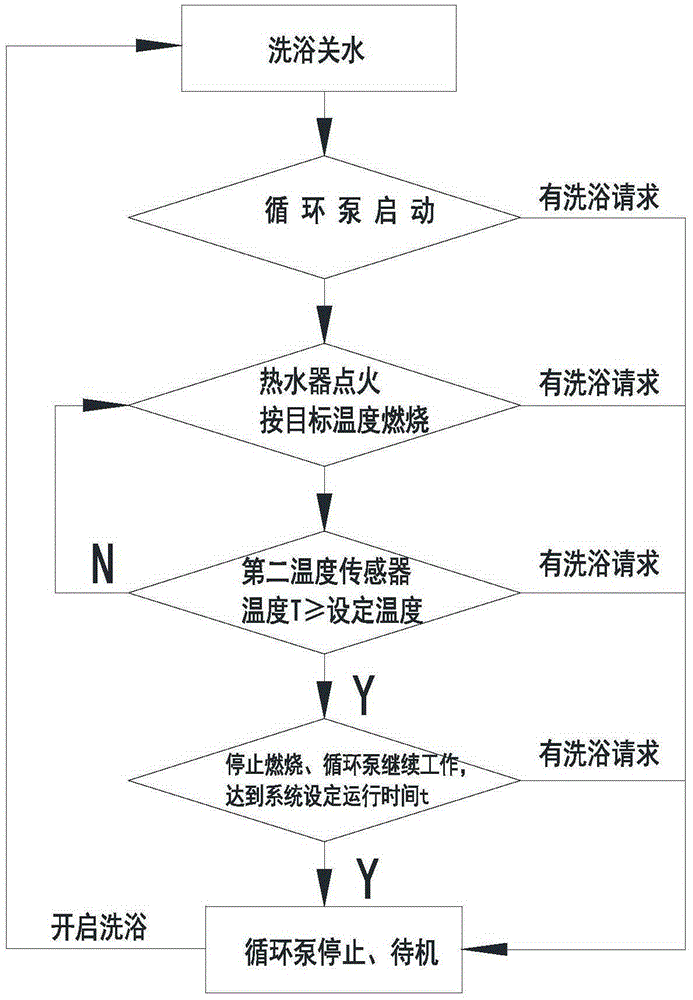

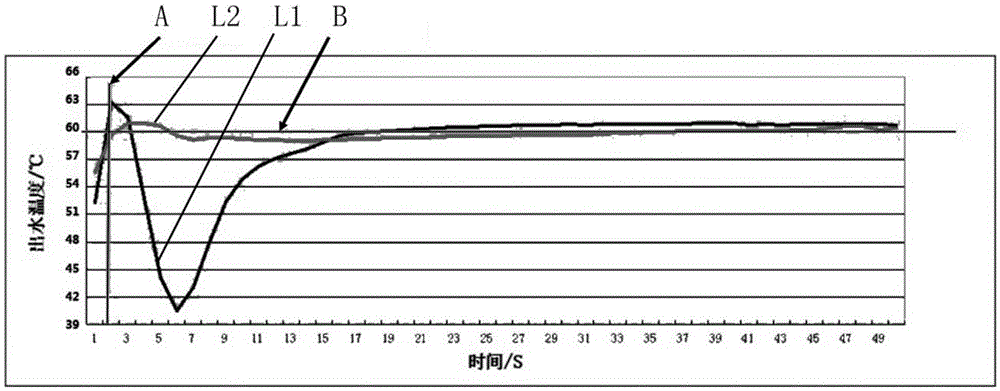

[0029] Such as figure 1 As shown, a constant temperature condensing gas water heater includes: a primary heat exchanger 1, a secondary heat exchanger 2, a water inlet pipe 3 and a water outlet pipe 4. The main heat exchanger for the heat generated by combustion, the secondary heat exchanger 2 is a condensation heat exchanger for absorbing waste heat in the flue gas, the primary heat exchanger 1 and the secondary heat exchanger 2 are connected by pipes, The water inlet pipe 3 is connected to the primary heat exchanger 1, and the water outlet pipe 4 is connected to the secondary heat exchanger 2; it is characterized in that a bypass pipe 5 is connected between the water inlet pipe 3 and the water outlet pipe 4, and in the bypass The pipe 5 is provided with a circulation pump 6 and a one-way valve 7, and the one-way valve 7 makes the water flow from the water outlet pipe 4 to the water inlet pipe 3 one-way.

[0030] Wherein, the secondary heat exchanger 2 is a water storage tank...

Embodiment 2

[0037] Such as Figure 4 As shown, the structure of the condensing gas water heater provided by this embodiment is basically the same as that of the first embodiment, except that the bypass pipe 5 is provided with a second water flow sensor 12 for monitoring the circulation flow. The first water flow sensor 9 is installed at the water inlet end of the water inlet pipe 3 . When the first water flow sensor detects the water flow signal, the circulation pump stops immediately and the gas water heater is ignited. When the water flow detected by the second water flow sensor 12 is lower than the set threshold, a signal is sent to the main controller of the gas water heater, and the main controller of the gas water heater sends a blockage alarm according to the signal.

Embodiment 3

[0039] Such as Figure 5As shown, the structure of the condensing gas water heater provided in this embodiment is basically the same as that of Embodiment 1, the difference is that the coil 11 is connected to the heat coil between the primary heat exchanger 1 and the water outlet pipe 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com