Concrete slump test vehicle

A concrete and slump technology, applied in measuring devices, instruments, scientific instruments, etc., can solve problems such as the inability to guarantee the levelness of the platform, the elongation of the sample height direction, and the need to improve the testing tools, so as to achieve a stable and effective mold removal process. , improve the integrity and improve the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

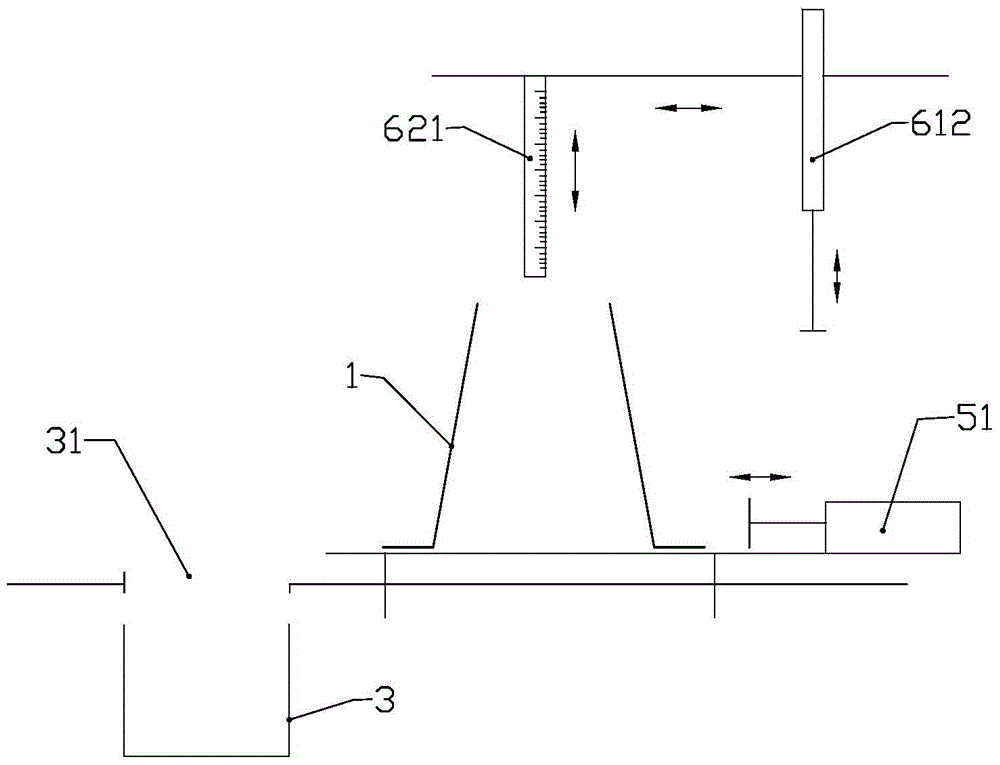

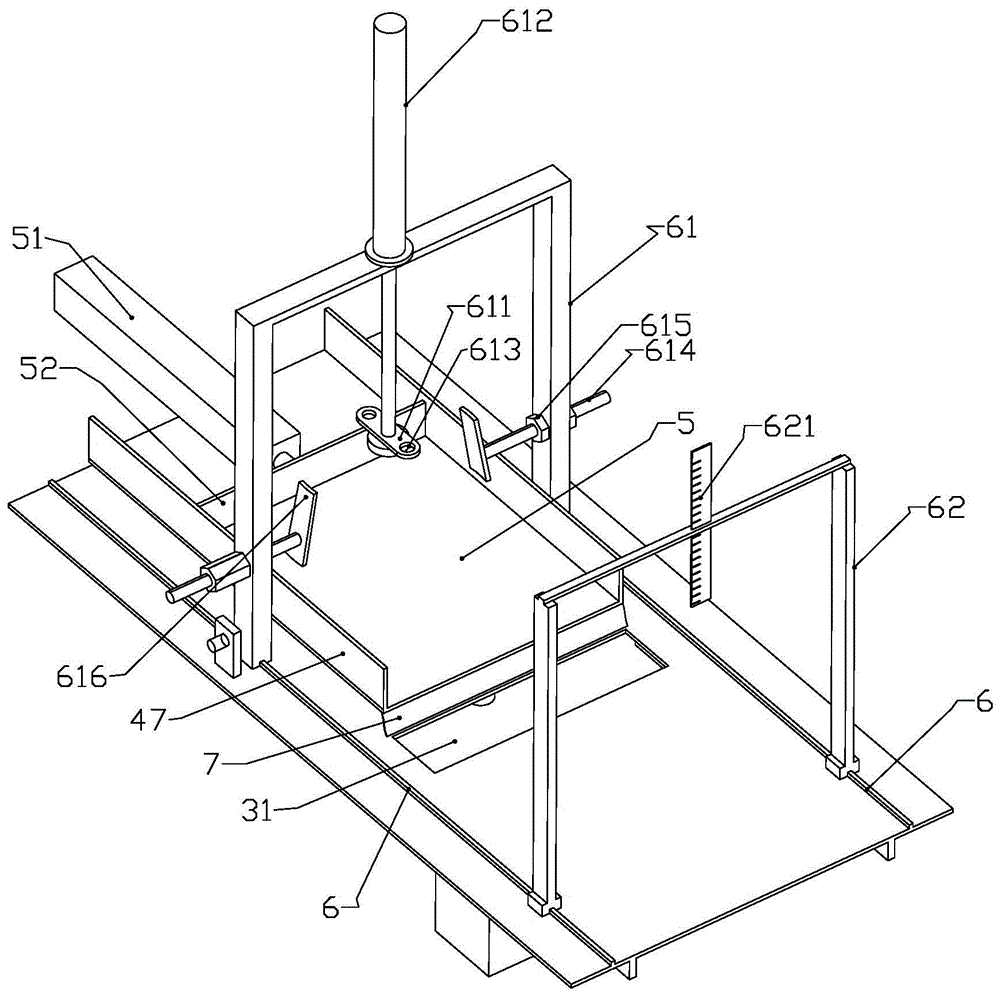

[0042] In response to the existing defects, a concrete slump test vehicle was developed, which was changed from a single test bucket to a test vehicle. The main purpose is to improve the accuracy and standardization of the test and avoid the adverse effects of human operation.

[0043] The basic principle is to change manual tamping to mechanical tamping. The intensity and time of tamping can be set to form standardization, increase the level adjustment function of the platform, form a horizontal state, and further improve the overall operability and Ease of operation.

[0044] Based on the above description, combined with Figure 2 to Figure 10 As shown, its structure is described in detail below:

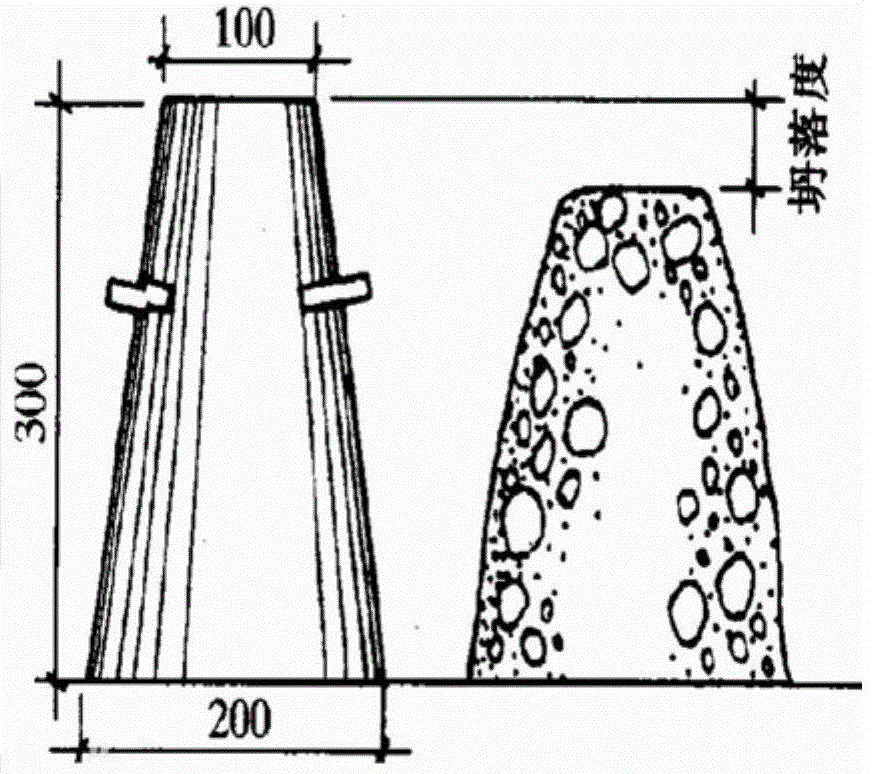

[0045] Test cylinder 1 is installed, and this test cylinder 1 is conical as a whole, as Figure 4 , the bottom of the test cylinder is provided with an outer flange 11 for contacting with the platform to increase the contact area. And side ear 12 is set on the outer upper part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com