Detection strip supplying mechanism and detection analyzer thereof

A detection strip and box body technology, applied in the field of detection analyzers, can solve problems such as unfavorable miniaturization of fully automatic detection analyzers, inability to achieve simultaneous detection of multiple items, and increase in manual operation errors, thereby reducing manufacturing costs and reducing space. , Improve the effect of detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

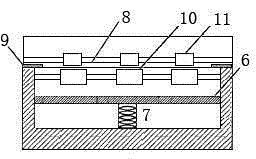

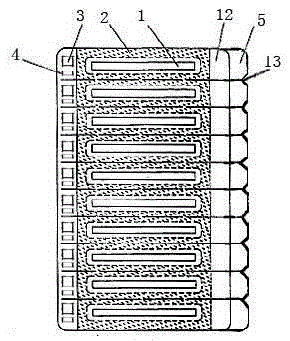

[0015] figure 1 It is a structural diagram of a single test box of the test strip supply mechanism of the present invention, each box body includes a base 6 and a compression spring 7 connecting the bottom plate of the box body and the base, and several test strip plates 8 are stacked on the base. There is a limit part 9 on the top of the box body, and the compression spring 7 presses the base to the top. At the same time, the limit part on the top of the box body can always limit the detection strip to the peeling position close to the output port. The output ports on the top of the box body are respectively A pick-up wheel 10 and a separation wheel 11 are provided, and the pick-up wheel 10 and the separation wheel 11 are connected with the motor, and the motor drives and cooperates with each other to separate and output the detection strips in the carton. When the program control system controls the motor to drive the pick-up wheel 10 When it rotates in the opposite directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com