Torque wrench calibrating instrument and calibrating method thereof

A technology of torque wrench and calibrator, applied in the field of torque wrench, can solve problems such as low efficiency, achieve high sensitivity, improve verification efficiency, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

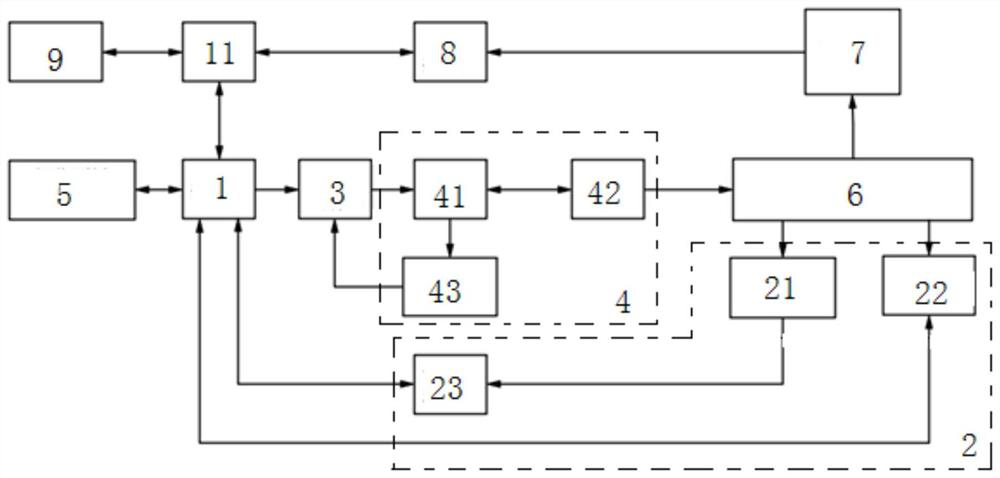

[0051] Embodiment 1 of the present invention provides a torque wrench calibrator, such as figure 1 As shown, it includes control assembly 1, data acquisition assembly 2, drive assembly 3, deceleration assembly 4, display assembly 5 and output shaft sleeve connector 6; the data acquisition assembly 2, drive assembly 3 and display assembly 5 are all connected to the control Component 1 is connected, the control component 1, drive component 3, deceleration component 4 and output shaft sleeve connector 6 are connected in sequence, one end of the output shaft sleeve connector 6 is connected with a torque wrench 7 with verification, and the other One end is connected with the data acquisition component 2;

[0052] In this way, with the above structure, the control assembly 1 receives external instructions and transmits them to the drive assembly 3, and the drive assembly 3 drives the deceleration assembly 4 to work according to the external instructions, and outputs the final torque...

Embodiment 2

[0093] Embodiment 2 of the present invention provides a verification method of a torque wrench verification instrument, which divides the range of the torque wrench 7 with verification into N shorts, that is, N times of loading, corresponding to N verification points, and the verification of each verification point includes the following step:

[0094] S1, initialize the torque wrench 7 with verification;

[0095] S2, inputting an external command;

[0096]S3, the control component 1 automatically sets the torque upper limit, automatically sets the rotation angle upper limit, automatically sets the loading rate, and automatically divides the test points according to the range according to the external command; and converts them into motor operation parameters;

[0097] S4, the drive assembly 3 controls the deceleration assembly 4 to work according to the parameters in S3;

[0098] S5, the data collection component 2 collects the torque of the verified torque wrench 7 in real...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com