A Online Prediction Method of Steel Plate Temperature Based on PLC

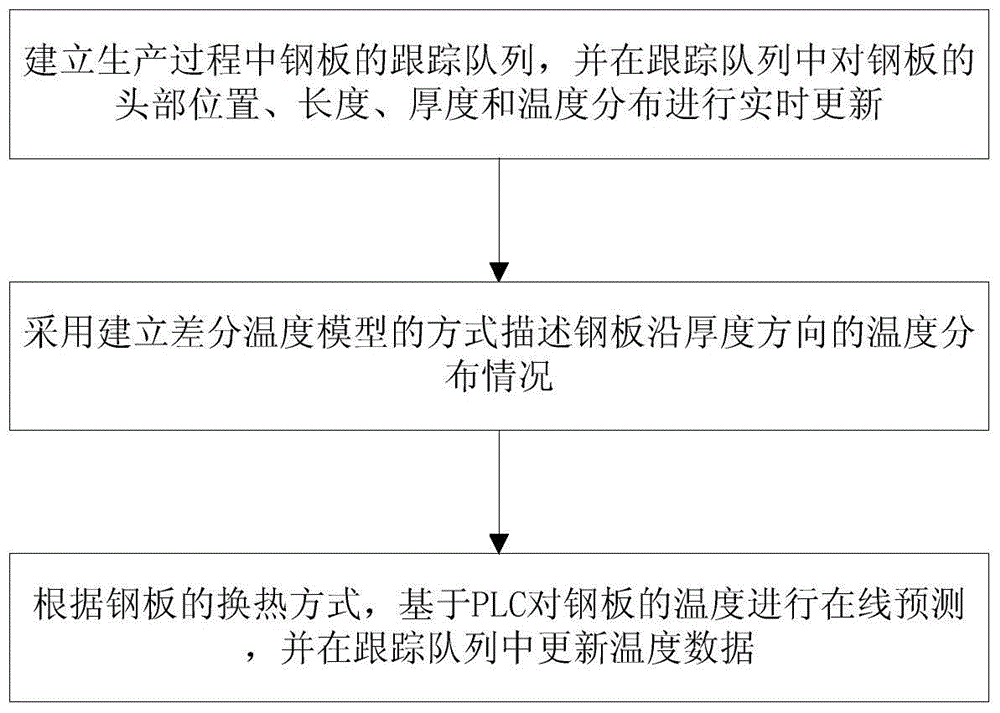

A prediction method, a technology of steel plate temperature, applied in the direction of temperature control, etc., can solve the problems of long calculation period of temperature model, unguaranteed calculation accuracy, and inability to realize high-speed calculation, etc., and achieve the effect of reducing communication links, fast calculation speed and rapid response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

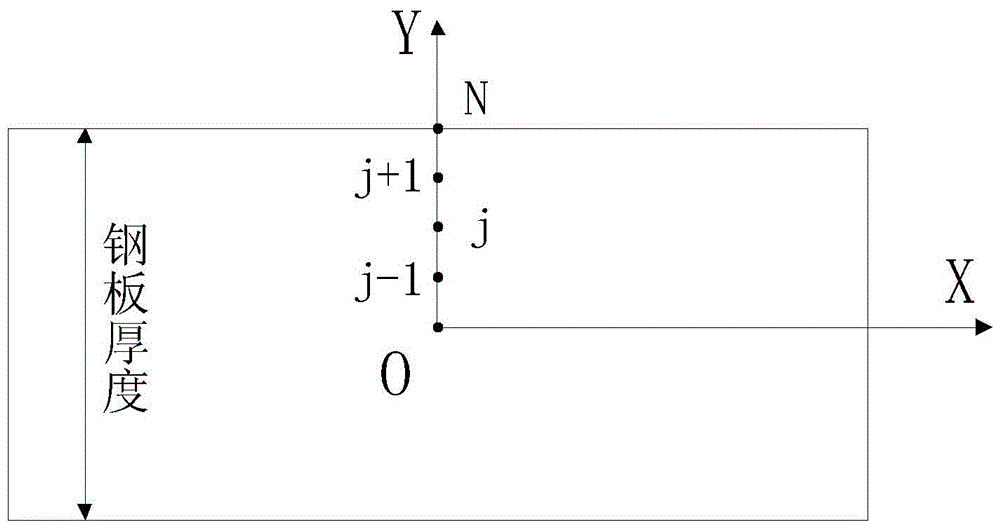

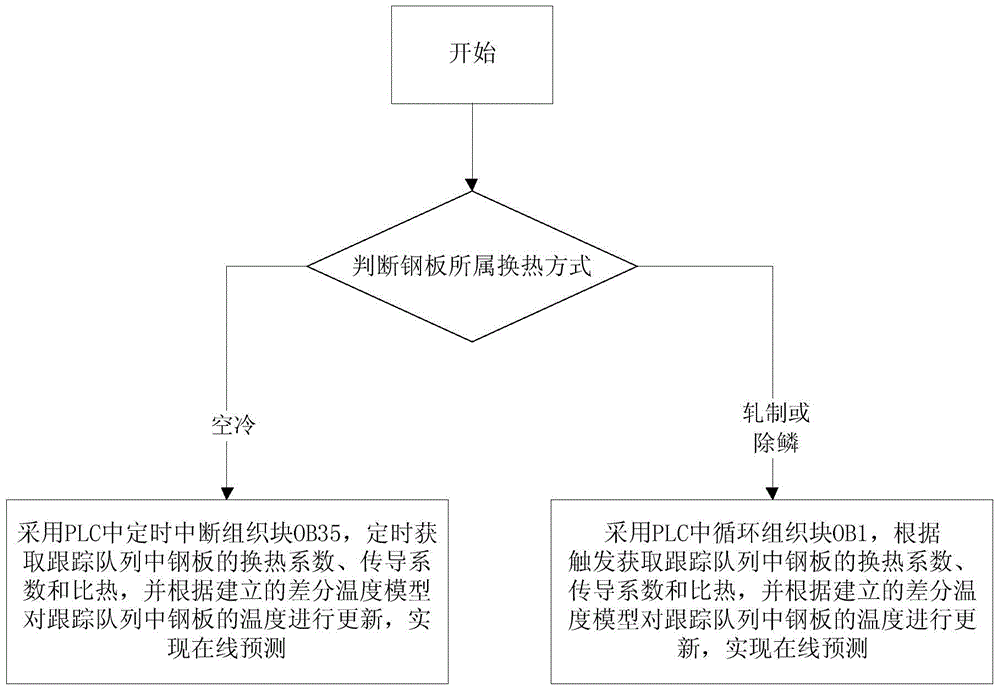

Method used

Image

Examples

Embodiment Construction

[0036] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

[0037] In the embodiment of the present invention, the steel plate temperature of a 3000mm medium and thick plate production workshop with two racks is selected to be predicted, and the calculation starts from the steel plate coming out of the furnace, and the whole product production process ends when the rolling is completed. The original data and process parameters of the rolled product are as follows:

[0038] ●Steel type: Q345

[0039] ●Blank specification: 230mm×1250mm×2250mm

[0040] ●Finished product size: 16mm×1750mm

[0041] ●Baking temperature: 1180℃

[0042] ●Rolling mill stiffness: 6500kN / mm

[0043] ●Zero rolling force: 20000kN

[0044] The rolling schedule is shown in Table 1, which includes 8 passes for rough rolling and 6 passes for finish rolling. Some rolling passes need to be descaled to remove the oxide scale on the surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com