Plate connecting method capable of using prepressing holes of soft rivet column and riveting compounding

A technology of plate connection and riveting column, which is applied in the field of plate connection, can solve problems such as unusability, influence on aesthetics, and limit breadth, and achieve the effects of low cost, improved appearance, and reduced height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0028] A board connection method using soft rivet post pre-pressed hole and riveting compound, comprising the following steps:

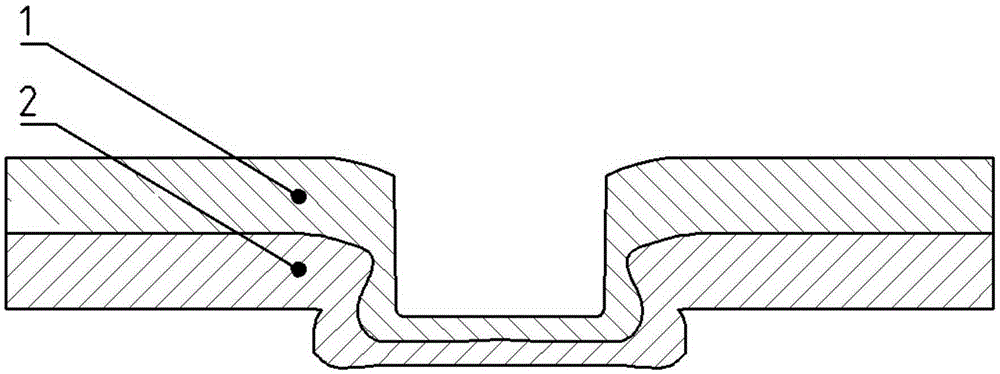

[0029] The first step, refer to figure 1 , using pre-pressed holes to create connection points on the upper plate 1 and the lower plate 2, mechanical deformation occurs between the upper plate 1 and the lower plate 2, thereby forming an inlay, so that the upper plate 1 and the lower plate 2 are connected together , there is a pit on the upper plate 1 and a protrusion on the lower plate 2, which affects its use in some occasions that require surface quality,

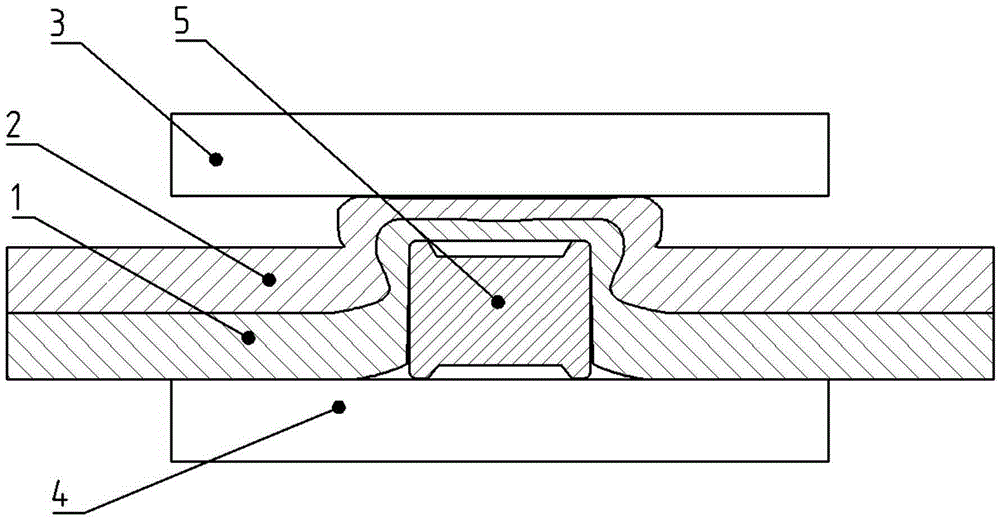

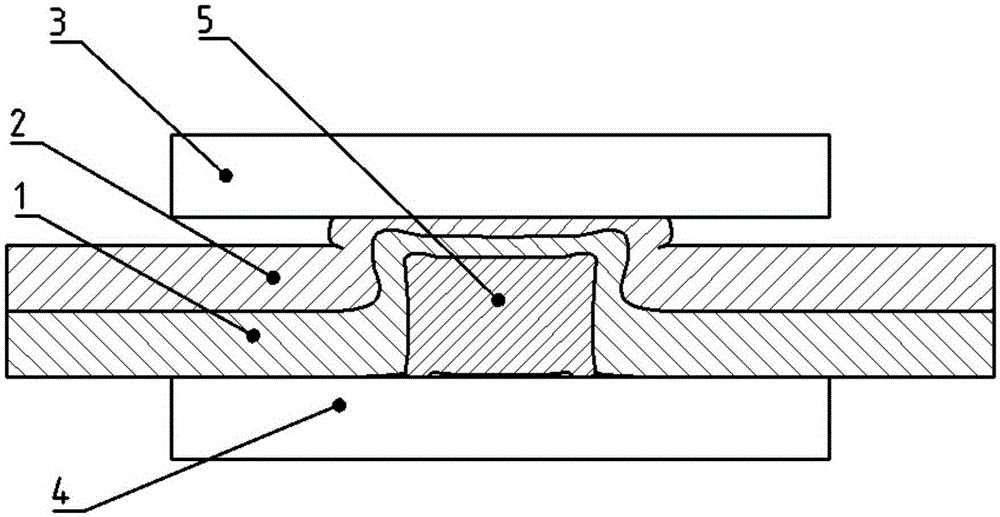

[0030] The second step, refer to figure 2 and image 3 , the upper plate 1 and the lower plate 2 are connected through the pre-pressed hole and the connection point formed is buckled on the rivet post 5, so that the rivet post 5 is placed in the pit on the upper plate 1, and the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com