Boring machine key milling bracket

A key milling and boring machine technology, which is applied in the field of milling key brackets for boring machines, can solve problems such as inability to process and affect processing progress, and achieve the effects of reasonable structural design, convenient cleaning, and convenient installation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

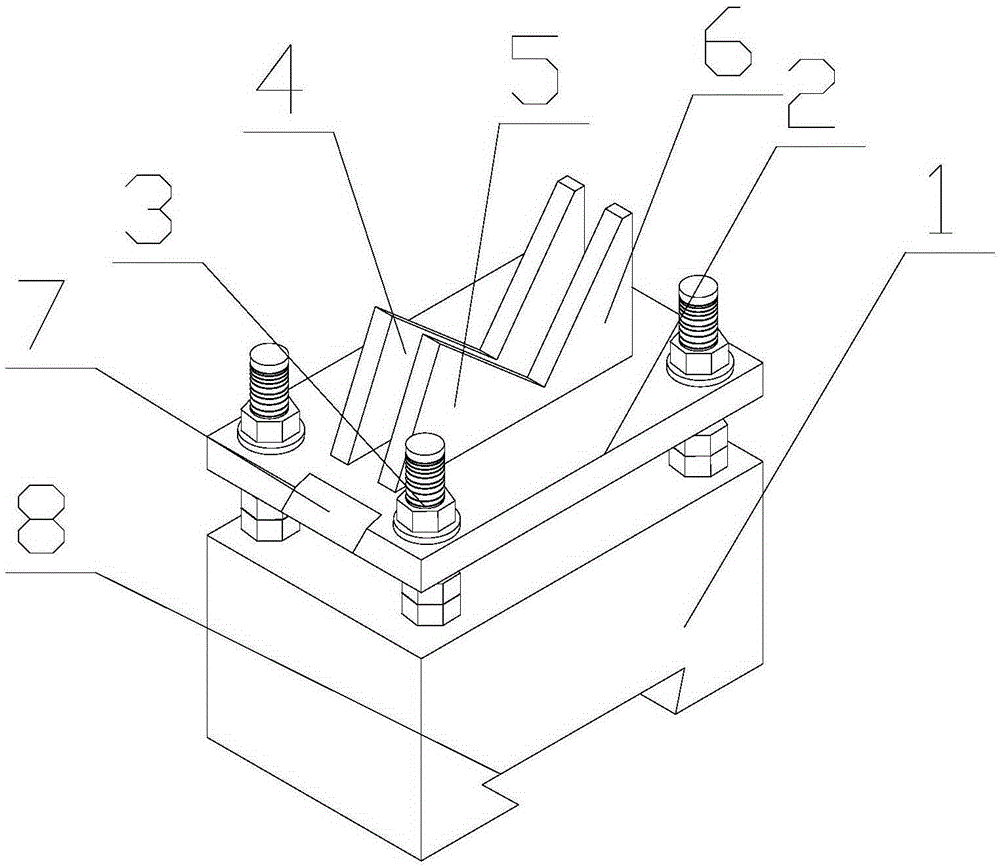

[0011] Referring to the accompanying drawings, the boring machine milling key bracket includes a base, the base is provided with a movable seat, an adjusting bolt is provided between the base and the movable seat, and a support block is provided on the movable seat, The support block includes a support seat a and a support seat b, and one end of the movable seat is provided with a chip removal groove.

[0012] Preferably, the support seat a and the support seat b are integrally welded and fixed on the movable seat, the support seat a is in the shape of an equilateral triangle, the support seat b is in the shape of a right triangle, and the The height of the supporting seat a is smaller than that of the supporting seat b.

[0013] Preferably, the bottom of the base is provided with guide rail grooves.

[0014] The device is installed on the guide rail of the boring machine, and can move freely to the bottom of the circular workpiece. In order to meet the processing accuracy, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com