Biomass pellet finished heat removal device

A technology of biomass particles and thermal devices, which can be used in heat exchanger types, lighting and heating equipment, direct contact heat exchangers, etc., and can solve problems such as accidents prone to occur.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

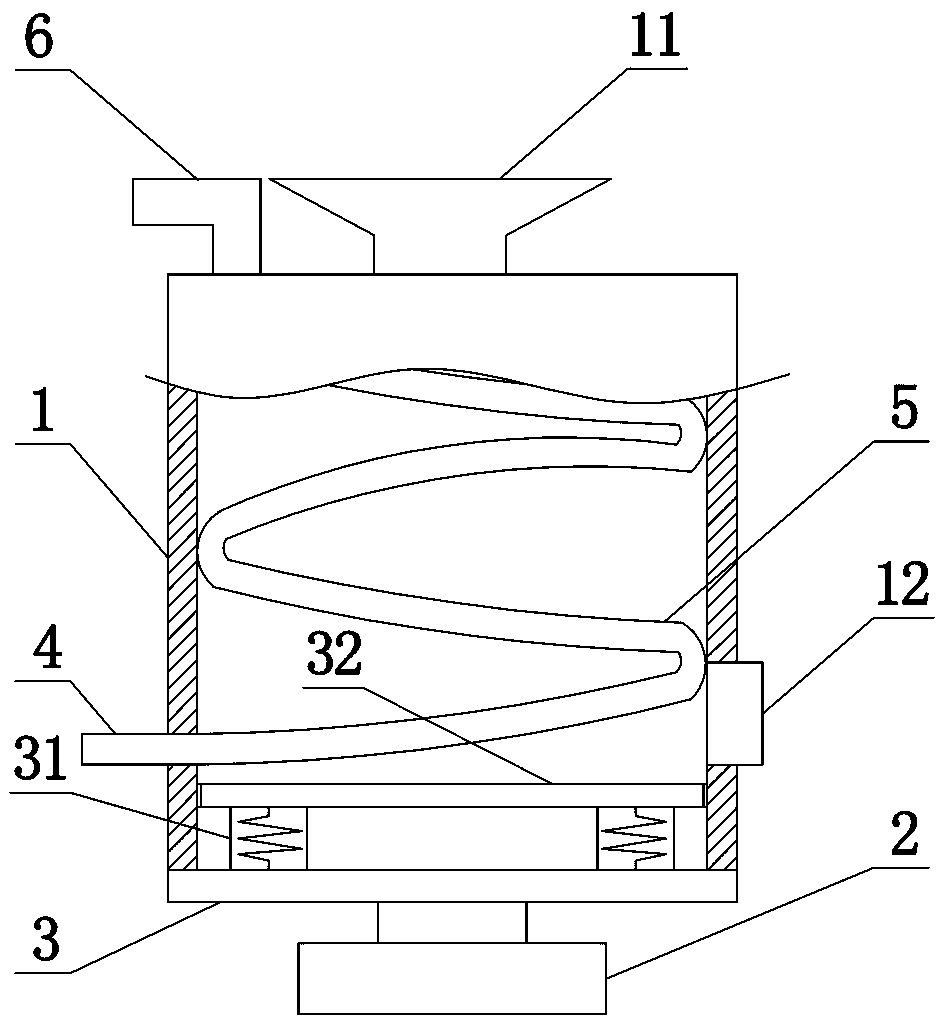

[0015] Such as figure 1 As shown, a kind of heat removal device for finished biomass particles, it includes a frame, a vibrating frame installed on the frame and a vibrating motor 2 driving the vibrating frame, the device can process the finished biomass particles containing heat Heat removal treatment is carried out to ensure that the produced biomass pellets do not contain heat. A heat removal cylinder 1 with an open bottom is installed on the frame, and the bottom of the heat removal cylinder 1 is sealed and connected with the vibrating frame, so as to ensure the airtightness of the entire heat removal cylinder. The vibrating frame is provided with a vibrating screen 32, and the biomass particles entering the heat removal cylinder 1 are vibrated by the vibrating screen to avoid sticking problems caused by long-term contact between bio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com