Subway overhead line system overhaul barrow

A catenary and pay-off car technology, applied in the direction of overhead lines, etc., can solve the problems of cumbersome use, waste of energy, difficult operation, etc., and achieve the effect of full utilization, convenient use and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the present invention is described in further detail:

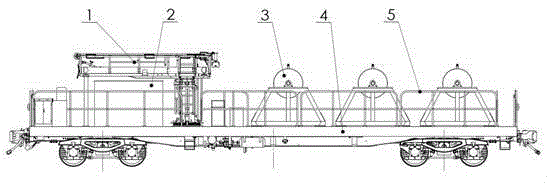

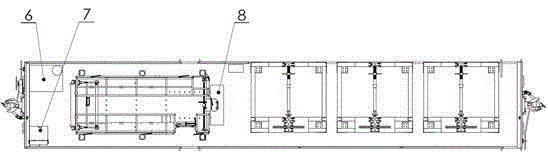

[0014] Such as figure 1 , 2 As shown, a kind of subway catenary maintenance pay-off car of the present invention comprises track flat car 4, and track flat car 4 is provided with generator set 2, electric control console 7 and hydraulic power unit 6, and track flat car 4 top is arranged There is a pay-off device 3 and a lifting and rotating operation platform 1, and working tools are arranged on the lifting and rotating operation platform 1. The track flat car 4 is used to carry the equipment on the car and walk on the track, and is pulled by a locomotive. The generator set 2 provides power for the whole vehicle. The hydraulic power unit 6 is used to drive the lifting and turning work platform 1 to lift and turn. Lifting and rotating operation platform 1 The lifting height range is 2.8 meters to 4.6 meters (from the rail surface), and the rotation range is 120° le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com