Preparation method for structured packing for oil-water separation

A technology for structured packing and oil-water separation, which is applied in separation methods, liquid separation, grease/oily substances/floating matter removal devices, etc. It can solve problems such as increased packing resistance, poor oil-water separation effect, and uneven coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

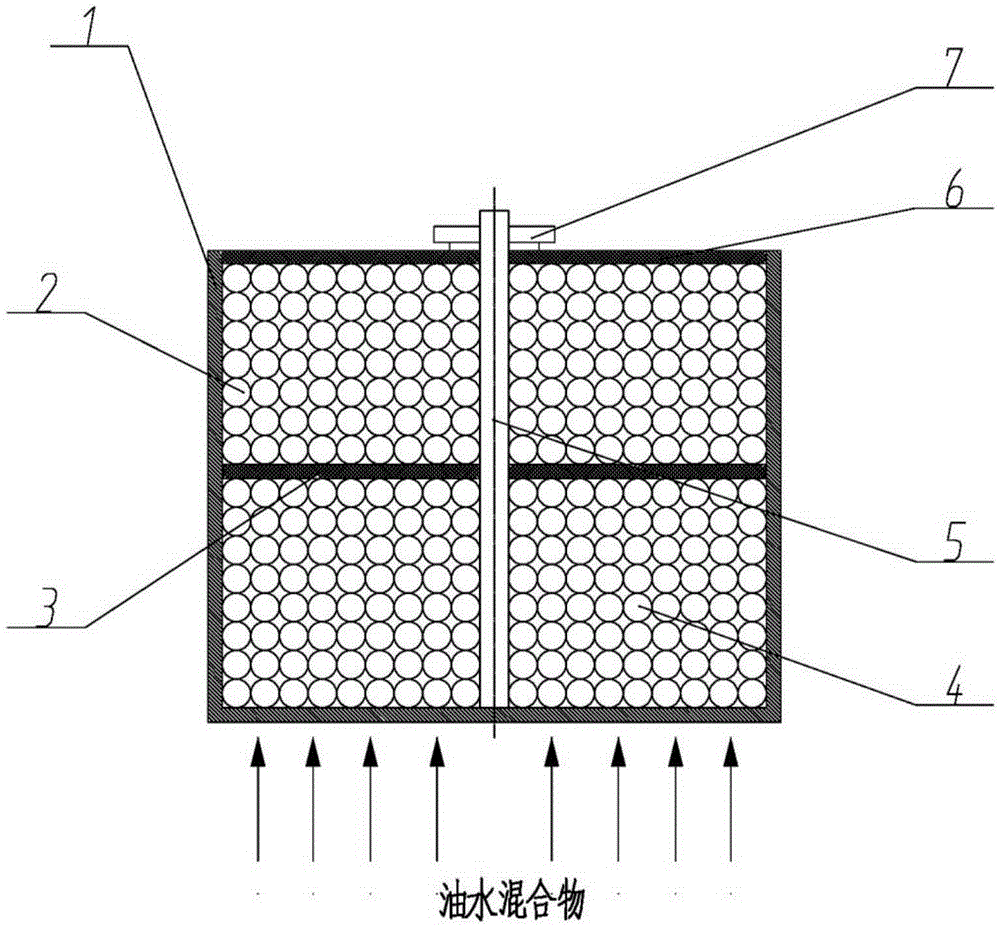

[0016] like figure 1 As shown, the present invention includes: cage 1, particle I2, separator 3, particle II4, shaft 5, cover plate 6, fastener 7; cage 1 is fixedly connected to shaft 5; In the upper area of the frame 1, the particles II4 are arranged in an orderly manner in the lower area of the cage 1, and the area where the particles I2 are located and the area where the particles II4 are located are separated into two areas by the partition 3; the cover plate 6 is located on the area where the particles I2 form The surface; the center of the partition 3 and the cover 6 has a through hole, and the shaft 5 passes through the through hole; the fastener 7 is located at the center of the upper surface of the cover 6 and locks the cover 6.

[0017] oil-water mixture along figure 1 In the direction of the arrow, that is, the lower surface of the structured packing used for oil-water separation enters the area where the particle II4 is located. Under the action of the pores f...

Embodiment 2

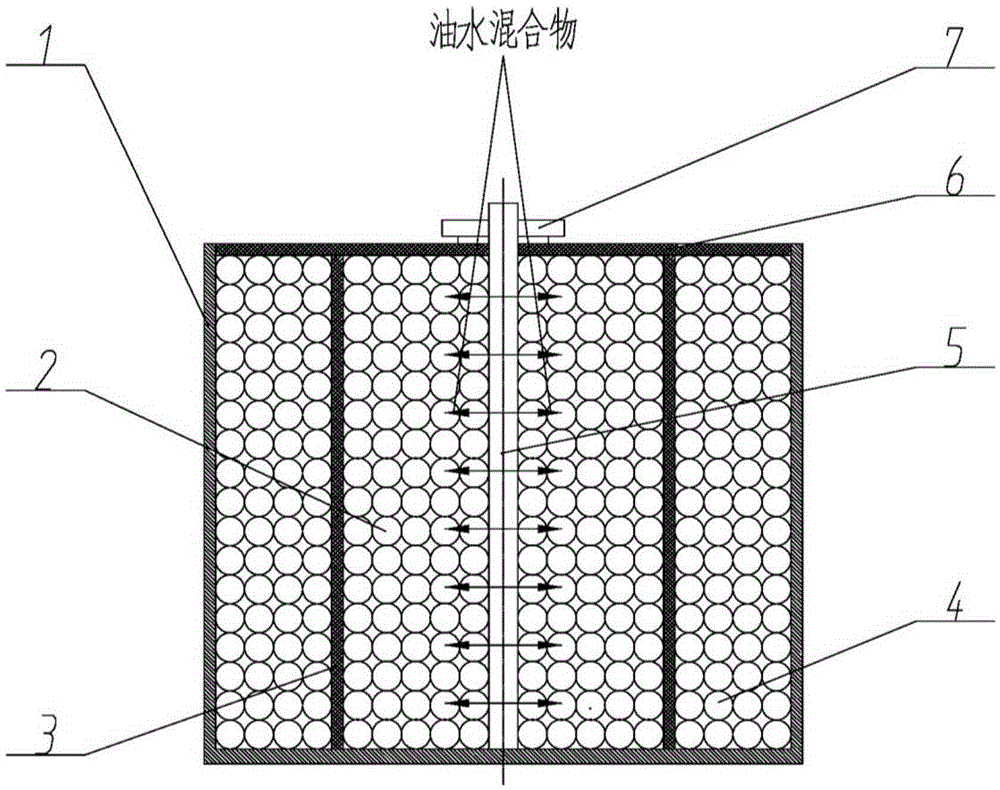

[0019] oil-water mixture along figure 2 In the direction of the arrow, that is, the shaft 5 of the structured packing used for oil-water separation enters the area where the particles I2 are located. Under the action of the pores formed by the particles I2, the oil-water mixture is atomized and divided into extremely fine liquid filaments and liquid droplets, because the material of particle I2 is a surface-modified material with super-oleophilic and super-hydrophobic properties, which increases the collision probability between the oil phase and particle I2, so that the oil phase in the oil-water mixture can easily flow on the particles The surface of I2 spreads and adheres, and finally coalesces into oil droplets and detaches from the surface of particle I2. However, the water phase in the mixture continues to move toward the outer ring to the area where the particle II4 is due to being repelled, and the water phase or the oil-water mixture that is too late to separate thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com