Method for producing a monofilament and use of the monofilament

A monofilament, thermoplastic polymer technology, applied in the field of preparation of monofilament and the application of the monofilament, can solve the problem of unattractiveness, and achieve the effect of improving bending recovery, low friction coefficient, and good bending recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The polymeric material used to make the monofilaments comprises preferably 10% to 99.99% by weight, more preferably 50% to 99.8% by weight, and especially 80% to 99.5% by weight polyester. Also included are preferably 0.01% to 50% by weight of nanoparticles, more preferably 0.2% to 10% by weight and especially 0.5% to 5% by weight of nanoparticles. The proportion of other additives is preferably 0% to 60% by weight, more preferably 1% to 40% by weight, and especially 2% to 20% by weight.

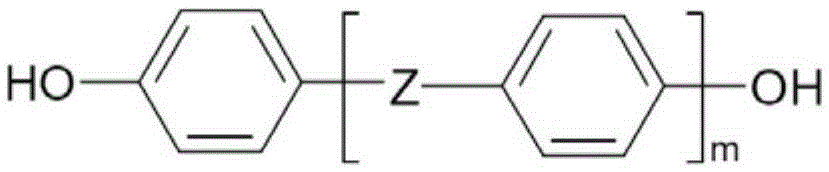

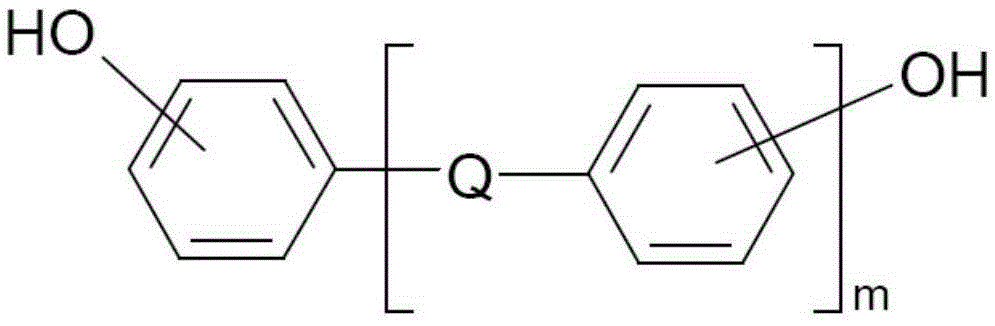

[0012] The polyesters in the thermoplastic polymer material are preferably polyesters based on aromatic dicarboxylic acids and aliphatic or aromatic dihydroxy compounds.

[0013] Preferred polyesters are polyalkylene terephthalates, especially polyalkylene terephthalates having 2 to 10 carbon atoms in the alcohol moiety.

[0014] Such polyalkylene terephthalates are known per se and are described in the literature. Its backbone includes an aromatic ring derived from an aromatic dica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com