Tire clamping type car carrier

The technology of a car carrier and a clip is applied to the buildings, building types, buildings, etc. where cars are parked, which can solve the problems of high requirements on the clear height of the parking space, high self-height, unstable transmission, etc., and achieves compact structure, controllable Precise and beautiful overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

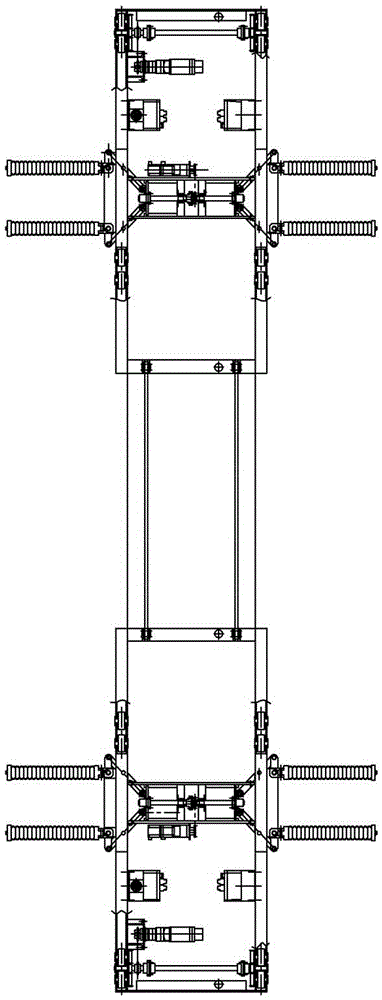

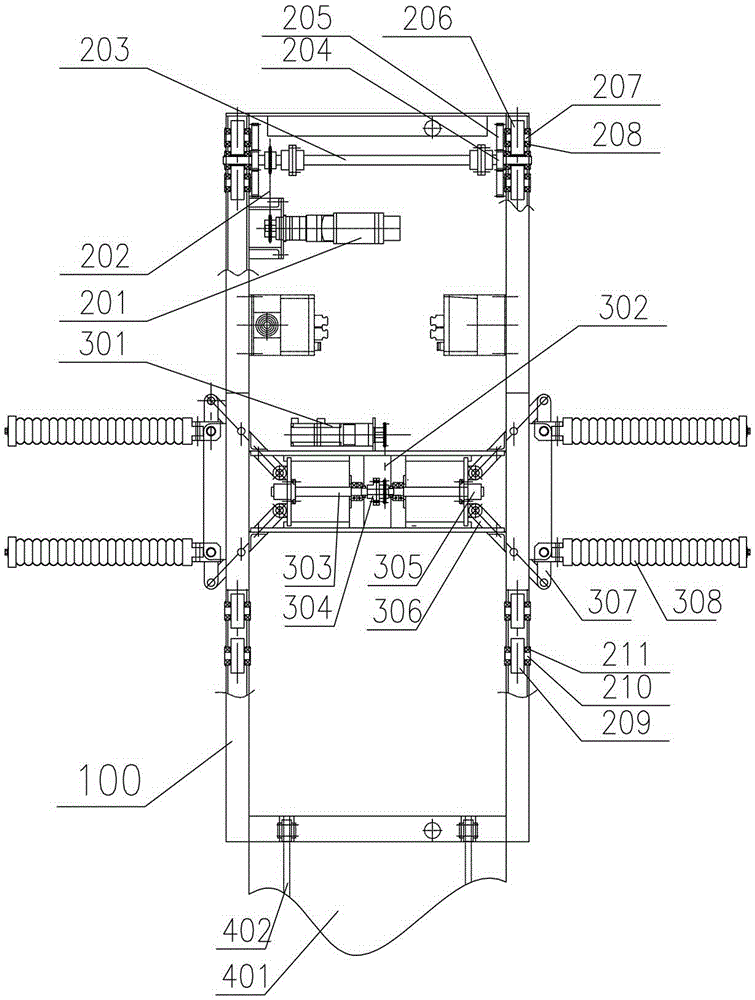

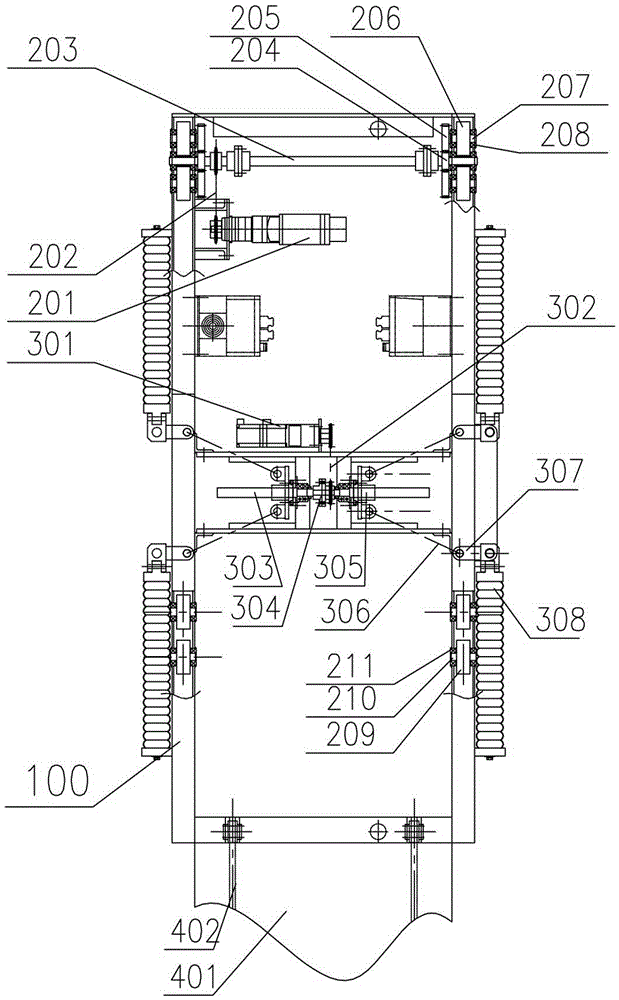

[0027] A vehicle carrier for holding and clamping tires includes two vehicle frames 100, and the two vehicle frames 100 are coaxially connected by a connecting mechanism. Both vehicle frames 100 are provided with a moving mechanism and a clamping mechanism.

[0028] The moving mechanism is provided with a servo motor 201 and traveling wheels. The servo motor 201 drives the traveling wheels to rotate through the chain, thereby controlling the movement of the carrier.

[0029] The clamping mechanism includes a clamping motor 301 and two pairs of arms 308 symmetrically arranged left and right. The clamping motor 301 controls the opening and closing of every pair of arms 308 through a transmission mechanism, so as to realize the putting and lifting of the automobile tires.

[0030] The moving mechanism and the clamping mechanism are further described below.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com