Hydraulic system, motor sweeper hydraulic system and motor sweeper with motor sweeper hydraulic system

A technology of hydraulic system and hydraulic oil, applied in the field of sweepers, can solve the problem of high cost and achieve the effect of reducing equipment cost, reducing requirements and saving size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

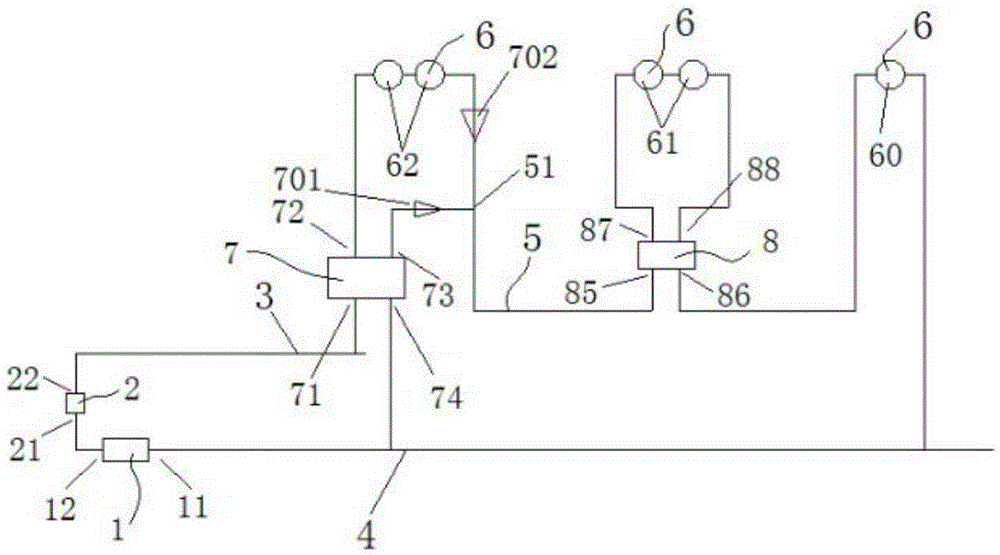

[0053] This embodiment provides a specific implementation of a hydraulic system, such as figure 1 As shown, the hydraulic system includes:

[0054] Hydraulic oil tank 1, used to store hydraulic oil, has a hydraulic oil inlet 11 and a hydraulic oil outlet 12;

[0055] The hydraulic pump 2 has a hydraulic pump inlet 21 and a hydraulic pump outlet 22, and the hydraulic pump inlet 21 communicates with the hydraulic oil outlet 12 through a pipeline;

[0056] The oil delivery pipe 3 communicates with the hydraulic pump outlet 22 and is used to supply the hydraulic oil in the hydraulic oil tank 1 to the hydraulic motor 6;

[0057] The oil return pipe 4 communicates with the hydraulic oil inlet 11 and is used to recover the hydraulic oil in the pipeline to the hydraulic oil tank 1;

[0058] There is at least one oil pipe 5, and its two ends communicate with the oil outlet of the oil delivery pipe 3 and the oil inlet of the oil return pipe 4 respectively;

[0059] There are multiple...

Embodiment 2

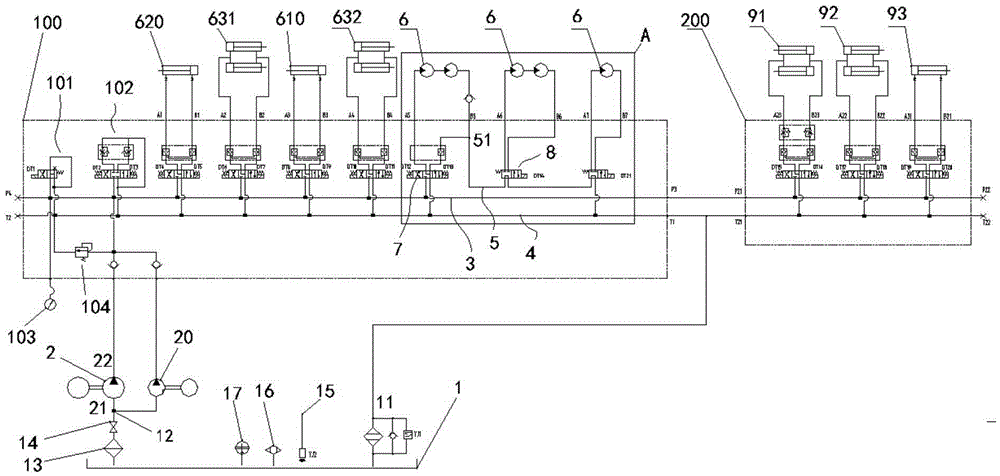

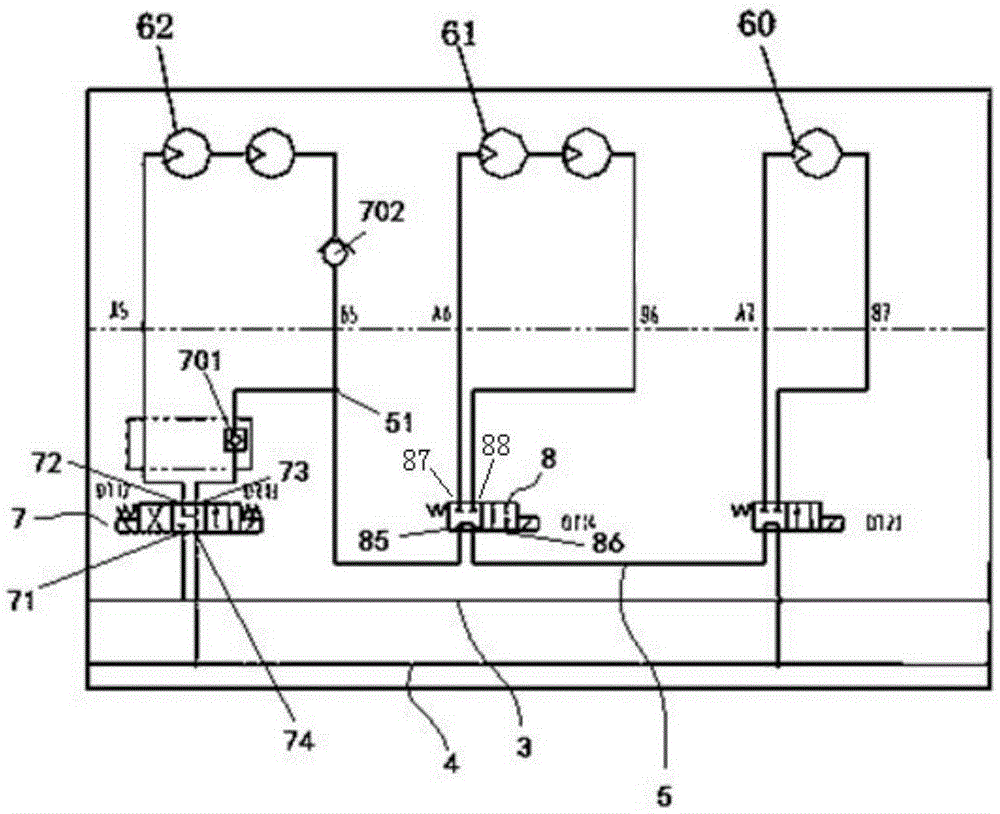

[0078] This embodiment provides a sweeping vehicle hydraulic system, which is a specific application of the hydraulic system provided in Embodiment 1, such as figure 2 and image 3 As shown, the sweeper hydraulic system includes:

[0079] Hydraulic oil tank 1, used to store hydraulic oil, has a hydraulic oil inlet 11 and a hydraulic oil outlet 12;

[0080] The hydraulic pump 2 has a hydraulic pump inlet 21 and a hydraulic pump outlet 22, and the hydraulic pump inlet 21 communicates with the hydraulic oil outlet 12 through a pipeline;

[0081] The oil delivery pipe 3 communicates with the hydraulic pump outlet 22 and is used to supply the hydraulic oil in the hydraulic oil tank 1 to the hydraulic motor 6;

[0082] The oil return pipe 4 communicates with the hydraulic oil inlet 11 and is used to recover the hydraulic oil in the pipeline to the hydraulic oil tank 1;

[0083] An oil pipe 5 is one, and its two ends communicate with the oil outlet of the oil delivery pipe 3 and th...

Embodiment 3

[0096] This embodiment provides a sweeping vehicle, which includes a hydraulic system, two left sweeping discs located on the left side of the sweeping vehicle along the traveling direction of the sweeping vehicle, two right sweeping discs located on the right side of the sweeping vehicle, and A rolling sweep at the bottom. Wherein, the hydraulic system is the hydraulic system of any one of the implementations described in Example 1 or Example 2.

[0097] Owing to having the above hydraulic system, it has the advantages described in any one of the above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com