A method for detecting robot precision using projection imaging of solid-liquid phase rapid conversion materials

A rapid conversion and imaging detection technology, applied in the direction of instruments, measuring devices, optical devices, etc., can solve the problems of multiple models, complex access structure, low efficiency, etc., to achieve enhanced test accuracy, high degree of intelligence, and convenient recycling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

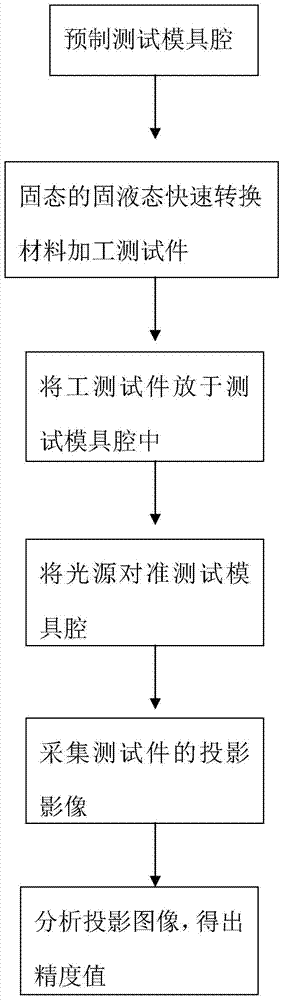

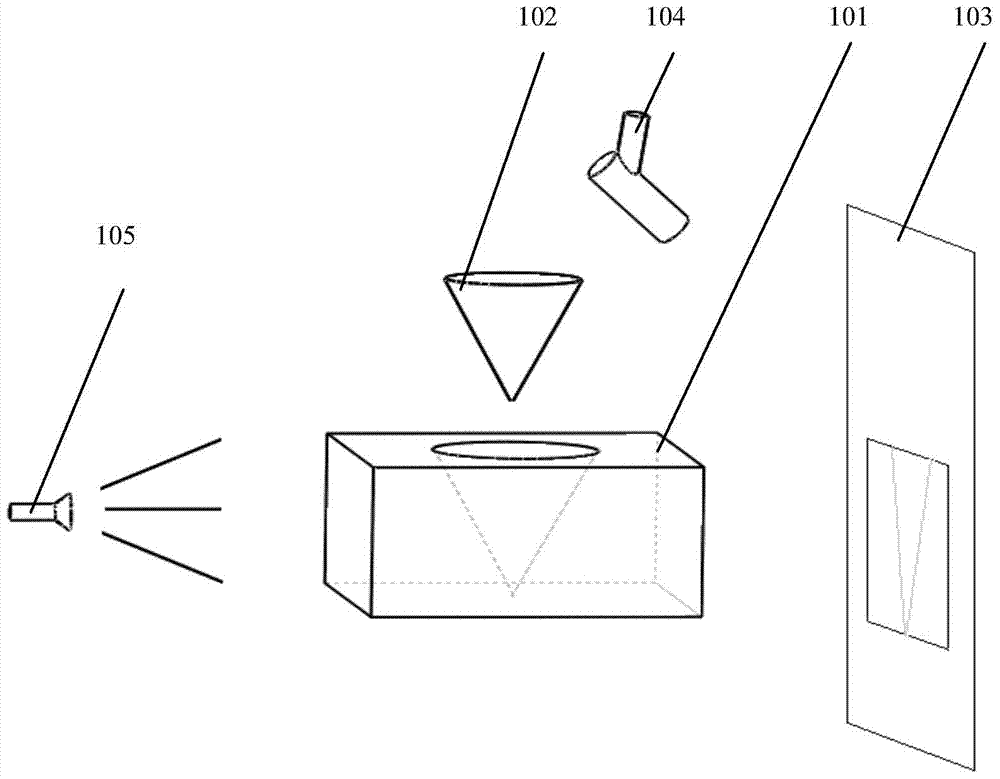

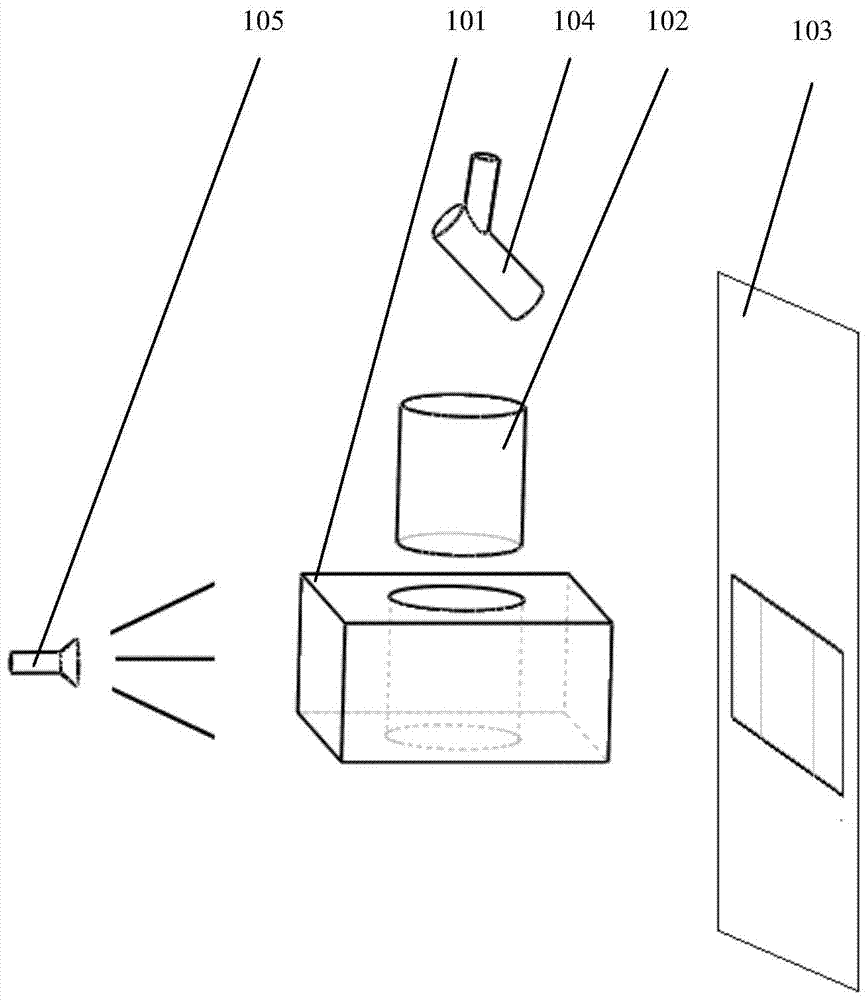

[0030] Such as Figure 1 to Figure 7 Shown: a method for detecting the accuracy of a robot using projection imaging of solid-liquid phase rapid conversion materials, the specific steps are as follows,

[0031] Step 1: Prefabricate a test mold cavity made of transparent glass, and the test mold cavity can be concave conical, circular, square, hexagonal, hemispherical, or in various shapes as required The combination;

[0032] Step 2: Use the tested robot to process ice cubes from -18 degrees Celsius to -4 into cones, cylinders, cuboids, tetrahedrons, cuboids, or hemispherical test pieces. Use dry ice mist to maintain the temperature of the ice c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com