Displacement sensor calibration device and method based on rotary table

A displacement sensor and calibration device technology, applied in the direction of measuring devices, electrical devices, instruments, etc., can solve the problem of inability to calibrate the displacement sensor, and achieve the effects of high calibration efficiency, small introduction error and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The application will be described in further detail below in conjunction with the accompanying drawings and specific embodiments:

[0040] The embodiments of the present application disclose a turntable-based displacement sensor calibration device and method.

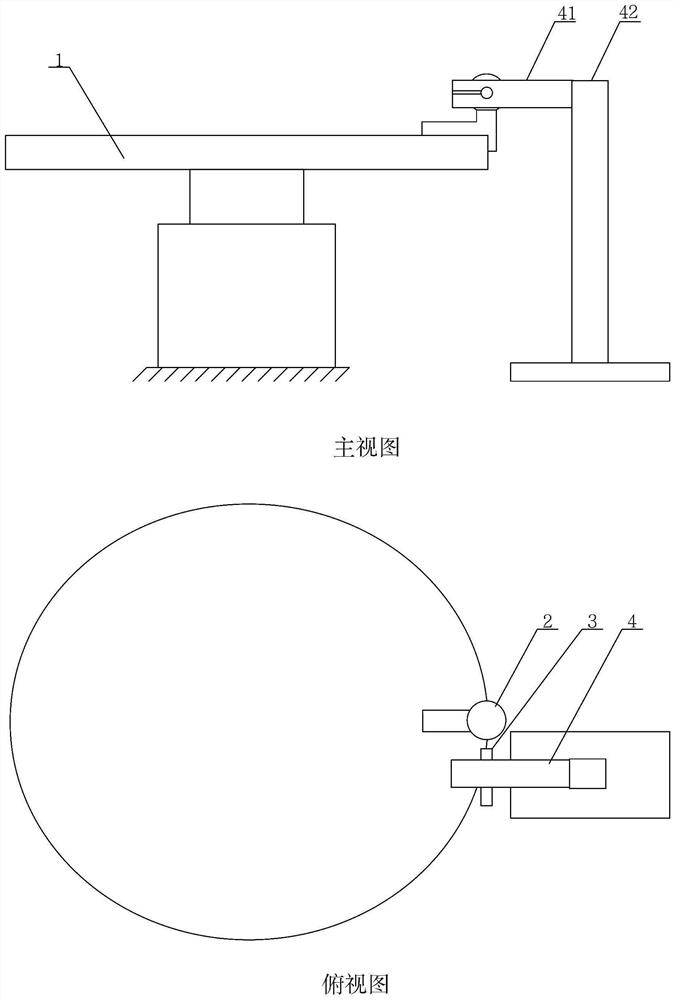

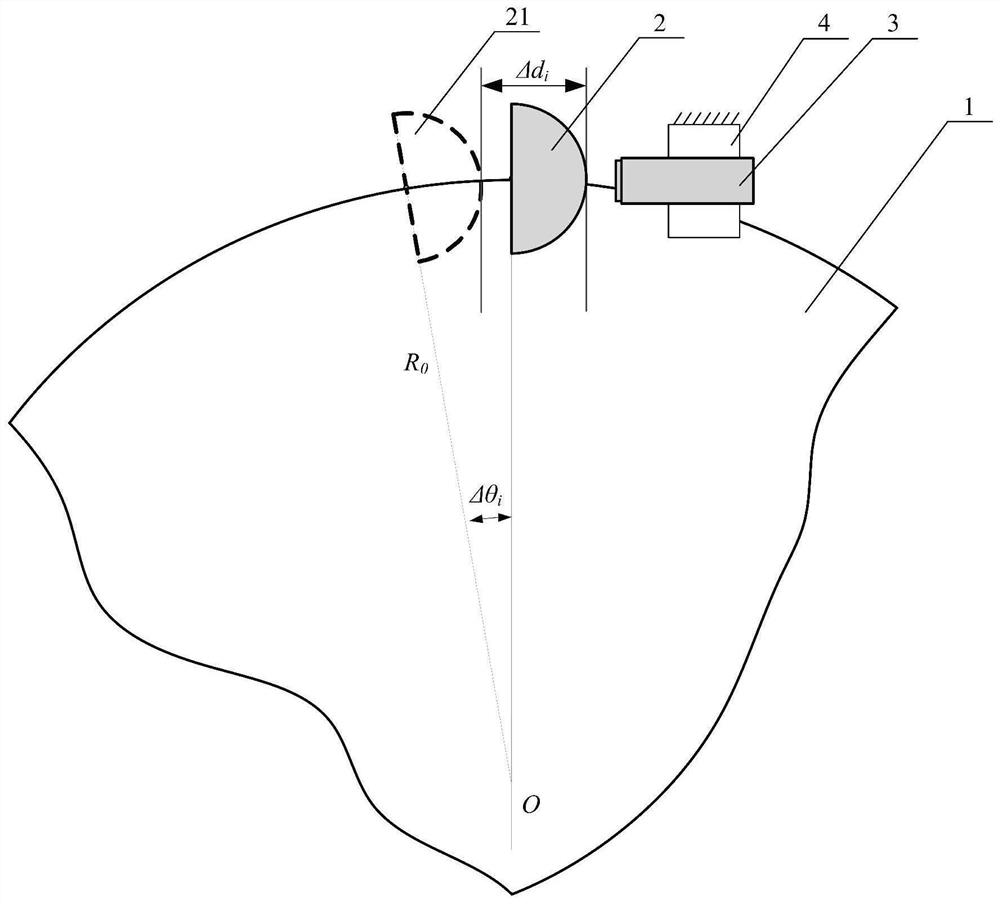

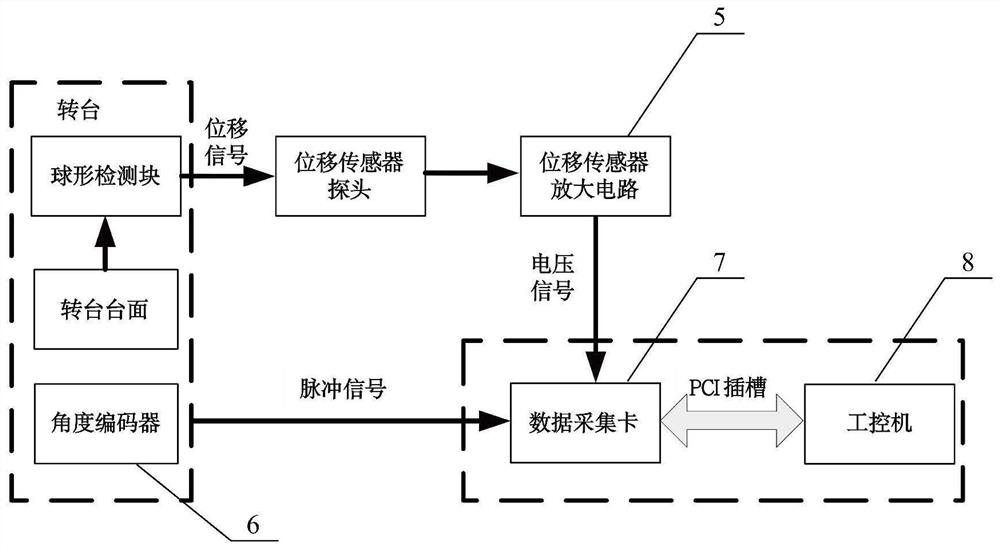

[0041] refer to Figure 1 to Figure 3 , a turntable-based displacement sensor calibration device, including a turntable 1, a spherical detection block 2, a displacement sensor probe 3, a displacement sensor fixed support 4, a displacement sensor conditioning circuit 5, an angle encoder 6, a data acquisition card 7, an industrial computer 8.

[0042] The turntable 1 is a precision turntable with angular position motion function, which can realize angular motion with higher resolution. The spherical detection block 2 is fixedly connected to the table surface of the turntable 1 to ensure that the outer edge of the table surface passes through the spherical center of the spherical detection block 2, that is, the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com