A non-contact high-precision tool setting system based on optical evanescent waves

A non-contact, high-precision technology, applied in metal processing equipment, measuring/indicating equipment, metal processing machinery parts, etc., can solve problems such as difficult tool calibration, difficult, and inability to form a precise contact interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

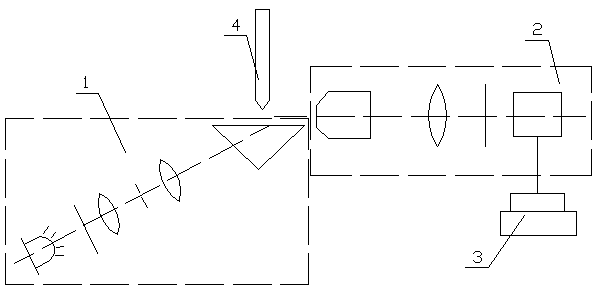

[0029] Such as figure 1 As shown, the present invention discloses a non-contact high-precision tool setting system based on optical evanescent waves, which is used to calibrate the tools 4 in mechanical equipment with high precision, including an evanescent wave generation module 1, a signal detection module 2 and a computer 3, the computer 3 is connected with the signal detection module 2.

[0030] The evanescent wave generation module in this embodiment is an existing known technology, and there are mainly three different configurations, namely:

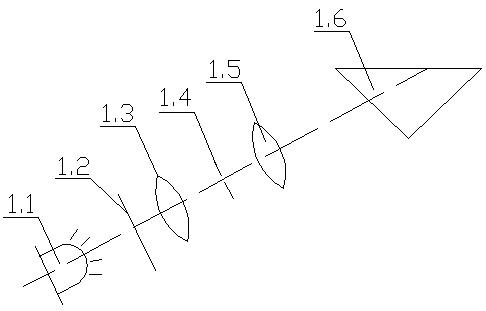

[0031] 1) if figure 2 As shown, the evanescent wave generating module 1 of the first configuration includes a first light source 1.1, a first polarization adjuster 1.2, a first convex lens 1.3, a first pinhole 1.4, a second convex lens 1.5 and a triangular prism 1.6, the first light source After the light emitted by 1.1 is adjusted to the P-type polarization state by the polarization adjuster 1.2, it passes through the first con...

no. 2 example

[0048] Such as Figure 7 , 8 , 9, the difference between the second embodiment and the first embodiment is that the optical axis of the signal detection module 2 is parallel to the normal direction of the evanescent wave interface generated by the evanescent wave generation module 1, and the signal detection module 2 It is arranged under the high refractive index medium of the evanescent wave generation module 1, and the objective lens of the signal detection module 2 is vertically facing the lower plane of the high refractive index medium of the evanescent wave generation module 1, and at the same time, the tool 4 enters the evanescent wave generation module 1 After the evanescent electromagnetic field layer, the cutter is within the field of view and depth of field of the objective lens.

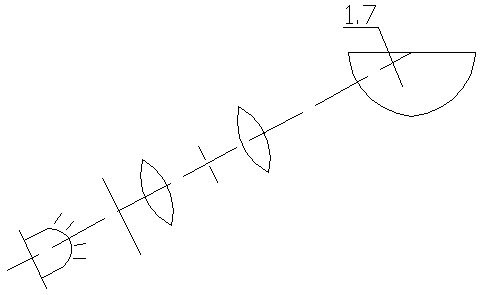

[0049] The above-mentioned high refractive index medium is: the triangular prism in the first configuration of the evanescent wave generating module, the hemispherical prism in the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com