Topological optimization design method for cold plate liquid flow channel of electric-electronic integration module

A technology of liquid flow channels and integrated modules, applied in the field of topology optimization design of cold plate liquid flow channels of power electronic integrated modules, can solve problems such as lack of theoretical basis, failure to achieve goals, and heat generation conditions that do not necessarily match.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments. The design method proposed by the present invention can optimize the design of the liquid flow channel layout for various heat dissipation structures. The heat dissipation area is uniformly generated in the following, and a point on the boundary of the area is a heat sink. Taking the problem as an example, the present invention will be described.

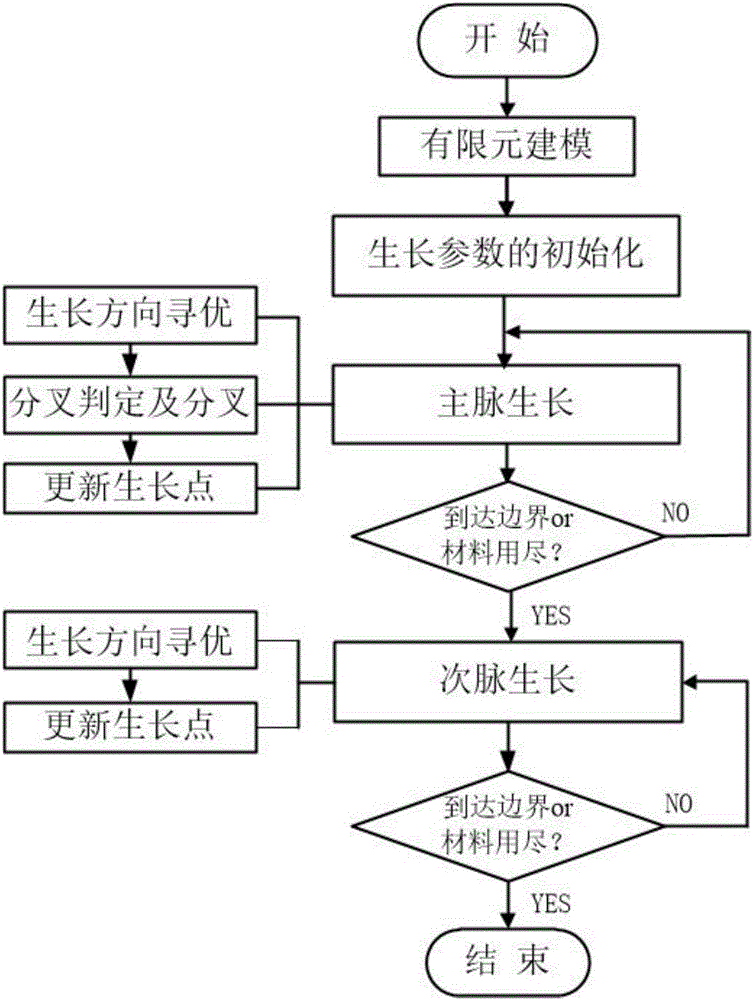

[0087] refer to figure 1 , a topology optimization design method for a cold plate liquid flow channel of a power electronics integrated module, comprising the following steps:

[0088] 1) Initialization of the adaptive growth of the cold plate liquid flow channel:

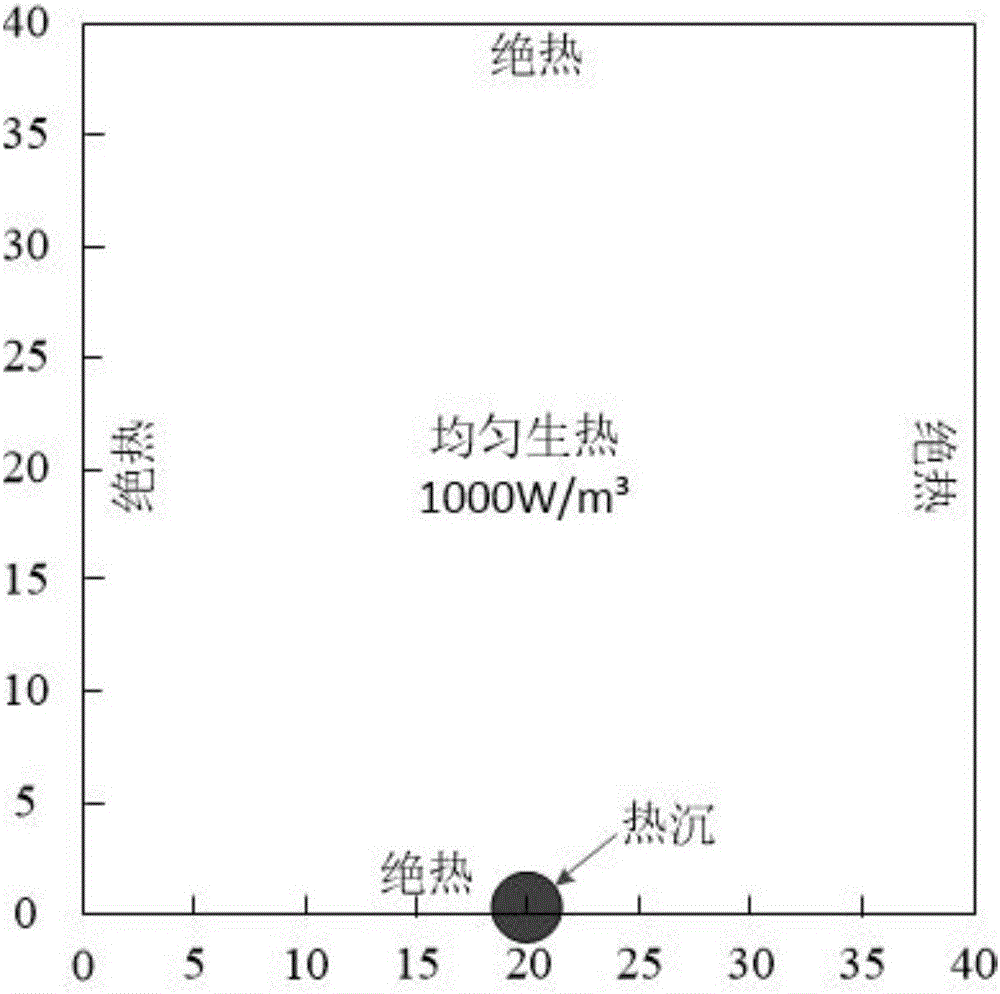

[0089] 1.1) Construction of the growth area: the base structure (radiation area) and its thermal load boundary conditions are as follows figure 2 As shown; the size of the area is 40mmX40mm; the heat is uniformly generated in the area, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com