Circuit breaker and solid-sealed pole thereof

A technology for solid-sealing poles and assembly holes, which is applied to high-voltage air circuit breakers, circuits, electrical components, etc., can solve the problems of contact surface wear, affecting the current conductivity performance of solid-sealing poles, and reducing the reliability of conductive contacts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

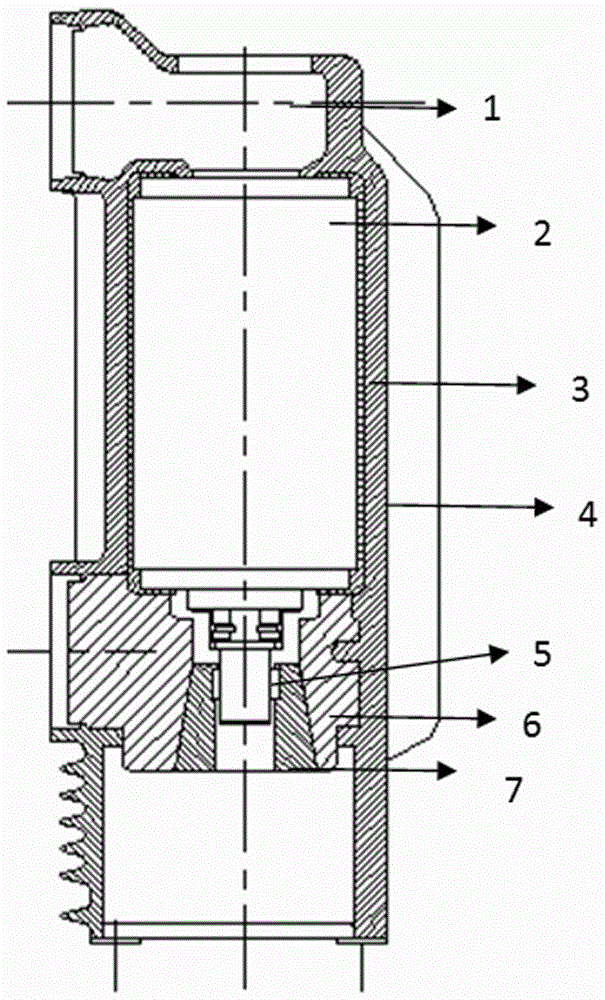

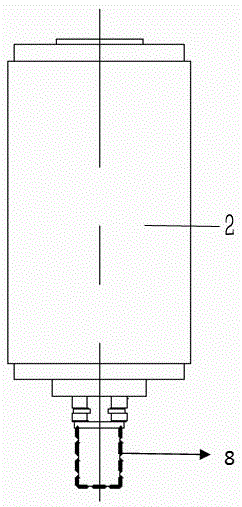

[0020] The embodiment of circuit breaker in the present invention: as figure 1 and figure 2 As shown, the circuit breaker is a DC vacuum circuit breaker, including the operating mechanism and several solid-sealed poles connected by transmission on the output end. Connect the upper outgoing line 1, the vacuum interrupter 2, and the lower outgoing line 6. The lower end of the vacuum interrupter 2 is provided with a vertically extending movable end conductive rod 8, and the movable end conductive rod 8 moves along the up and down direction and is mounted on the lower outgoing line 6. In the upper and lower extension assembly holes opened, the bottom of the hole wall of the assembly hole is a tapered hole section that gradually increases from top to bottom, and the conductive hole sleeved on the outer circumference of the movable end conductive rod 8 is fixed in the tapered hole section through the cooperation of the tapered surface. Sleeve 7, the inner hole of the conductive sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com