Photoelectric tracking detecting mechanism for cold frame bending machine

A photoelectric tracking and detection mechanism technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of steel wires hindering the stability of on-site operation machines, broken steel wires, and difficulty in realizing online control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

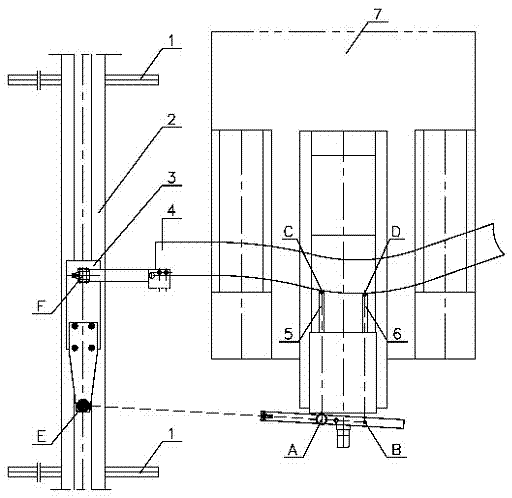

[0018] The present invention is a photoelectric tracking detection mechanism for rib cold bending machine or profile forming machine, characterized in that the photoelectric tracking detection mechanism includes

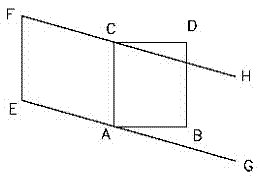

[0019] Probing rods, the probing rods include first probing rods 5 and second probing rods 6 arranged in parallel, the ends of the first probing rods 5 and the second probing rods 6 are always pressed against the tested section steel 4 edge;

[0020] A cross bar, the cross bar is connected with the first probe rod 5 through a hinge A, the cross bar is connected with the second probe rod 6 through a hinge B, and the probe rod is close to the end point of the processed steel 4 to the hinge connected with the cross bar The distance between the axes is the theoretical length of the probe rod, and the theoretical lengths of the first probe rod 5 and the second probe rod 6 are consistent;

[0021] The trolley 3, the movement track of the trolley 3 is parallel to the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com