Moisture content dynamic testing device and moisture content testing system

A technology of dynamic testing and moisture content, applied in the field of geotechnical engineering, to achieve continuous feedback and overcome the effect of dynamic real-time detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

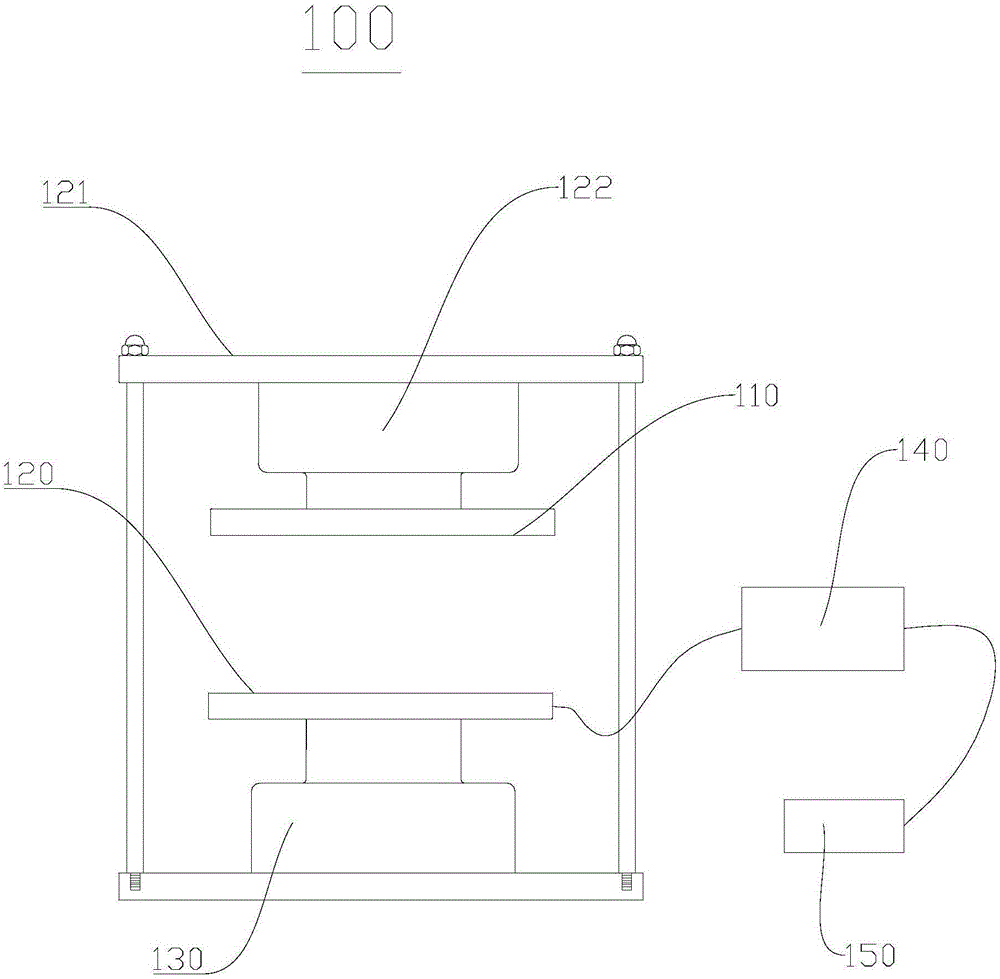

[0034] Please refer to figure 1 , the embodiment of the present invention provides a moisture content dynamic testing device 100 , which includes a first squeeze plate 110 , a second squeeze plate 120 , a loading device 130 , a resistance tester 140 and a control system 150 .

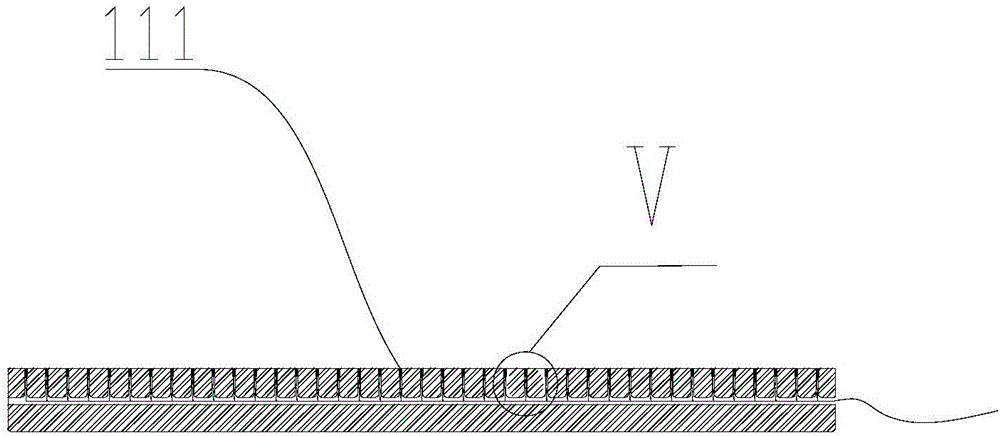

[0035] The first squeeze plate 110 is the working surface of the whole device, the soil sample is placed on the first squeeze plate 110, and the bottom of the first squeeze plate 110 is connected with a loading device 130, so that the first squeeze plate 110 can be Lift up and approach the second squeeze disc 120, thereby realizing the squeeze of the soil sample. In this embodiment, the surface of the first squeeze disc 110 used to place the soil sample has a certain roughness, and the working surface of the second squeeze disc 120 used to squeeze the soil sample also has a certain roughness . In this way, it can be ensured that in the process of extruding the soil, the soil sample will be consolidate...

no. 2 example

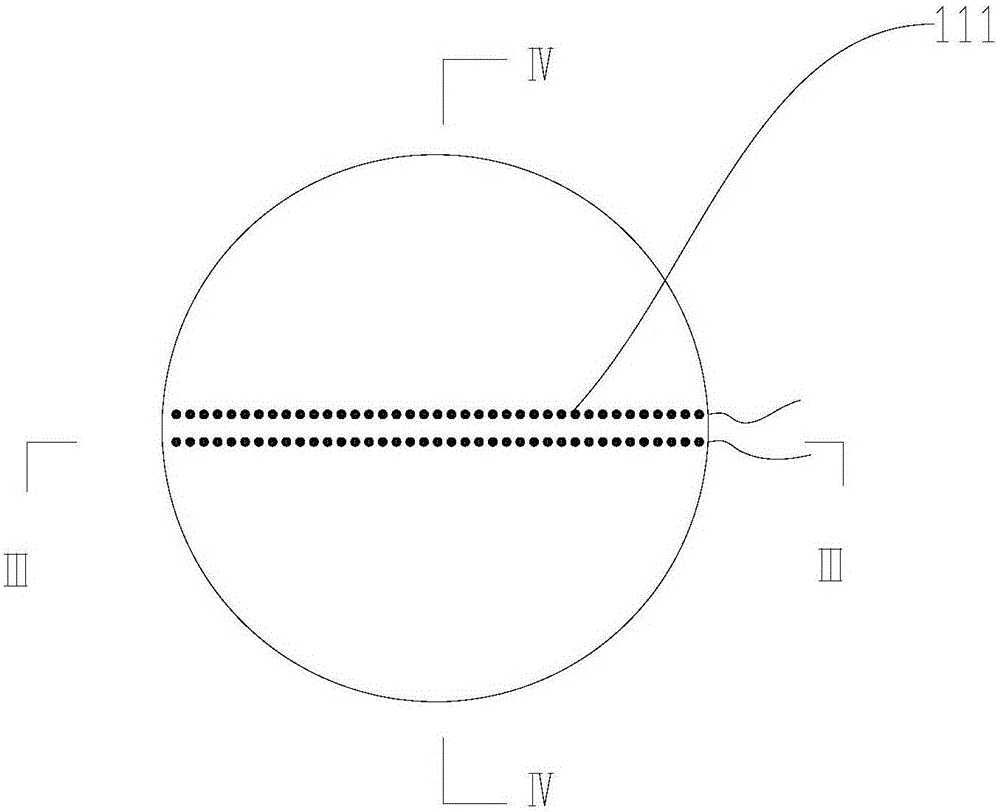

[0053] Please refer to Figure 7 The difference between this embodiment and the first embodiment is that the first extrusion disk 110 and the second extrusion disk 120 are both circular, and the pairs of electrode holes on the first extrusion disk 110 are based on the first extrusion disk. The center of the circle of the pressure plate 110 is the center, and is arranged in a manner of radiating around the first pressure plate 110 . The electrodes 111 are disposed in the electrode holes. This radial arrangement can test the moisture content distribution of the extruded soil sample more comprehensively and accurately.

[0054] The test process is as follows: the resistance tester 140 measures the resistance values of multiple rows of electrode pairs, the control system 150 collects the data, and the software system processes and fits the data. Specifically, during the testing process, the control system 150 averages the resistance measurements at multiple locations at the sa...

no. 3 example

[0058] An embodiment of the present invention also provides a moisture content testing system, including a moisture analyzer for testing the average moisture content of the soil before compression and the moisture content dynamic testing device in the first embodiment or the second embodiment. It can measure the moisture content of soil more comprehensively.

[0059] It should be noted that the above-mentioned moisture meter can be selected from other devices for measuring moisture content such as chemical moisture meters in the prior art.

[0060] During use, the average moisture value of multiple groups of soil samples to be tested before being compressed is measured by a moisture analyzer to obtain multiple groups of soil samples with known moisture content, and then use the first embodiment or the first embodiment The moisture content dynamic testing device in the second embodiment tests the resistance value of these soil samples with known moisture content, thereby the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com