Method for formation lithology analysis while drilling in gas drilling

A technology of gas drilling and formation lithology, which is applied in material analysis using radiation diffraction, earthwork drilling, wellbore/well components, etc., which can solve the problems of high analysis cost, inability to analyze formation while drilling, and inability to accurately determine mineral components And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0114] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0115] Such as Figure 7 Shown, the gas drilling of the present invention analyzes the method for stratum lithology while drilling,

[0116] Determination of cuttings late arrival time;

[0117] Obtain the cuttings corresponding to the depth of the well according to the late arrival time of the cuttings. The cuttings are obtained every 1 to 2 meters according to the drilling depth from shallow to deep;

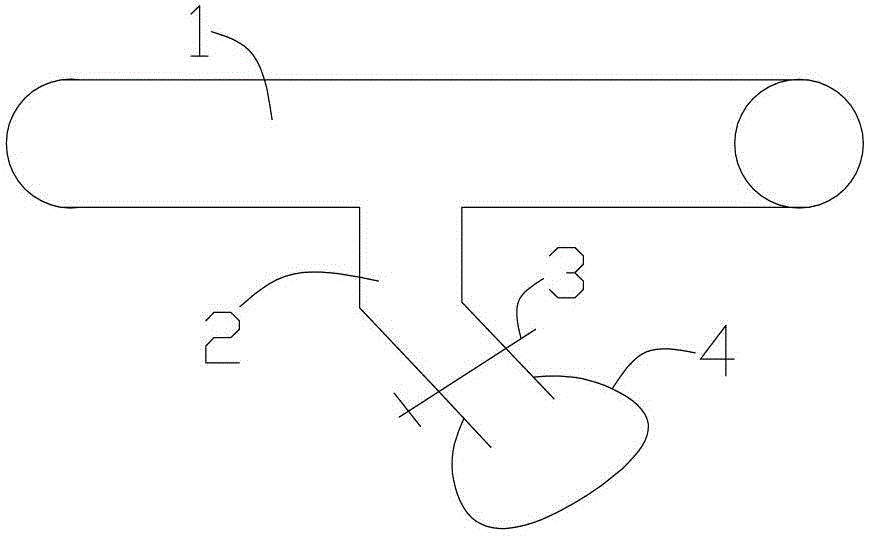

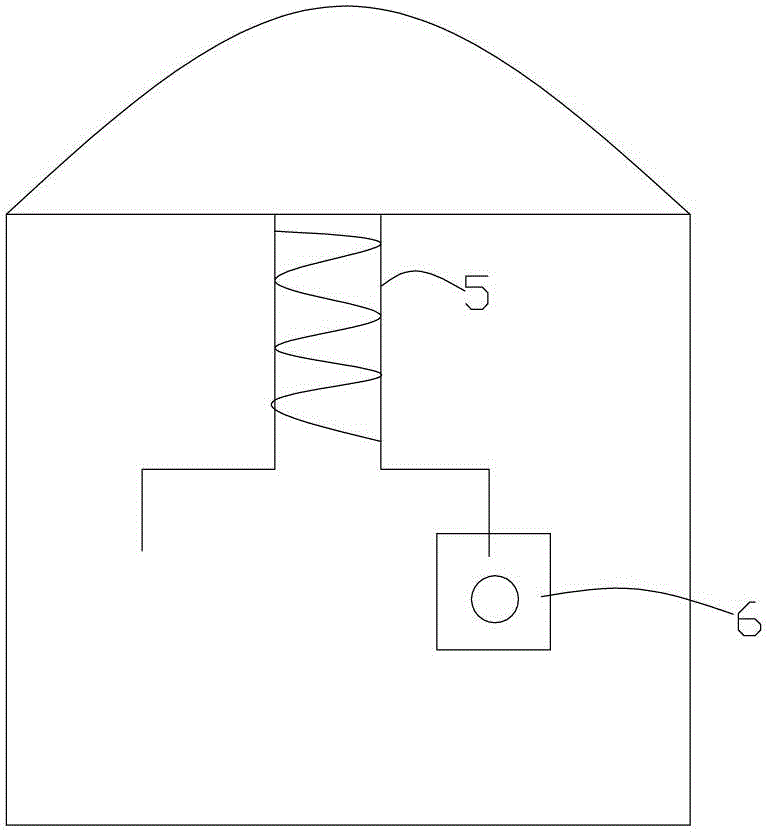

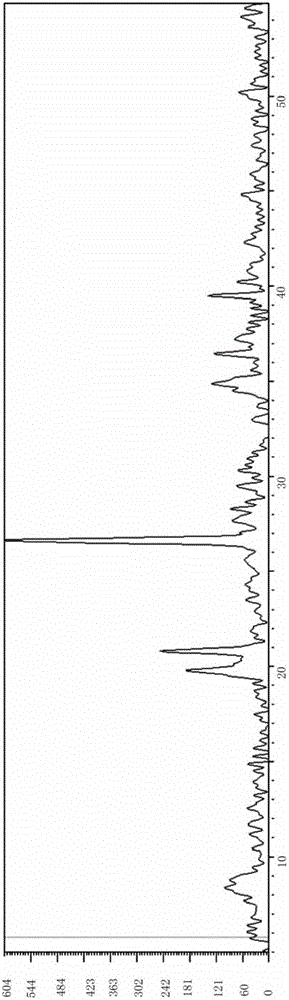

[0118] X-ray diffraction analysis of the cuttings is carried out at the drilling site after each cuttings acquisition, and the X-ray diffraction data of the cuttings are obtained, and the lithology is judged at the drilling site through the X-ray diffraction data: firstly, the X-ray diffraction pattern is obtained according to the X-ray diffraction data, Then compare the X-ray diffraction pattern with the mineral composition database to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com