A Chipless Cutting Machine for Irradiation Boxes

A technology of irradiation box and cutting machine, which is applied in the direction of metal processing machinery parts, clamping, support, etc., can solve the problem of chip-free cutting, etc., and achieve the effect of compact structure, stable operation and good safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

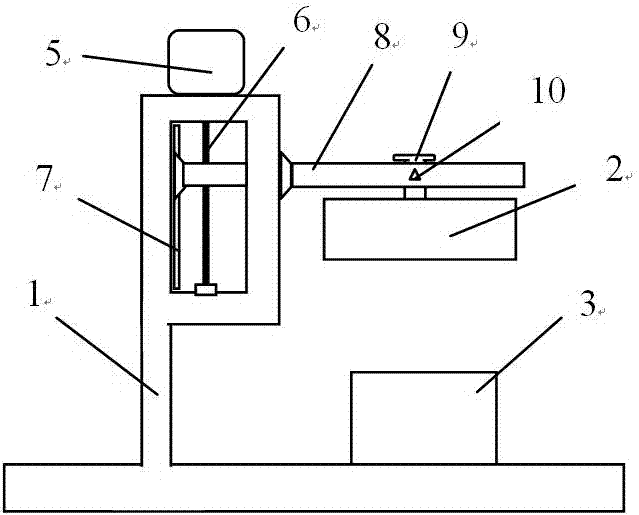

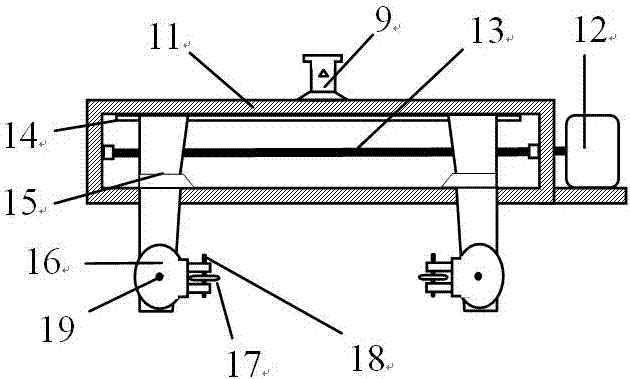

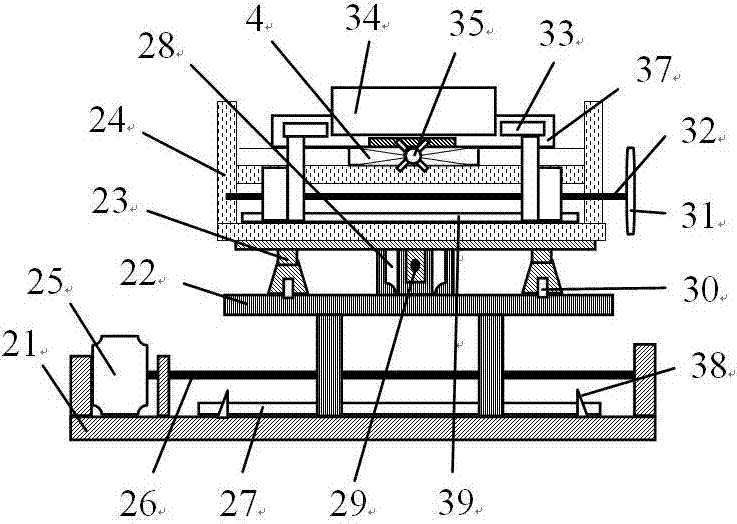

[0031] figure 1 It is a schematic layout diagram of the overall structure of an irradiation box chipless cutting machine of the present invention, figure 2 It is a schematic diagram of the cross-section structure of the cutting mechanism in the present invention, image 3 It is a schematic diagram of the cross-section structure of the tooling table in the present invention, Figure 4 It is a schematic top view of the tooling platform in the present invention, Figure 5 It is a schematic diagram of the longitudinal section structure of the cutting mechanism in the present invention, Figure 6 It is a schematic top view of the clamping platform in the present invention, Figure 7 It is a schematic diagram of the longitudinal section structure of the clamping platform in the present invention, Figure 8 It is a schematic diagram of the longitudinal section structure of the square irradiation box slot in the present invention, Figure 9 It is a schematic diagram of the longi...

Embodiment 2

[0048] Figure 9 It is a schematic diagram of the longitudinal section structure of the circular irradiation box slot in the present invention. The structure of this embodiment is the same as that of Example 1, the difference is that the cylindrical irradiation box 34 in this embodiment is selected to match it The positioning of the draw-in slots 37, the positioning columns 41 at the bottom of the draw-in slots 37 of different structures are all matched with the positioning slots 40 on the lifting platform 4 faces. like Figure 9 shown.

[0049] In the present invention, the blade rest 16 can be arbitrarily arranged within 90 degrees of the horizontal direction downwards under the drive of the motor V20 to adapt to the cutting requirements of different irradiation boxes, but the blade 17 should be as close as possible to the The cut surface of the irradiation box 34 is vertical. And when the blade 17 is not set horizontally to cut a square, especially a cylindrical irradiat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com