Chassis secondary positioning device

A secondary positioning and chassis technology, applied in workpiece clamping devices, metal processing, metal processing equipment, etc., can solve the problems of many curved surfaces, the feeding jaws cannot meet the feeding requirements of the chassis, etc., to achieve high precision and expand support. range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

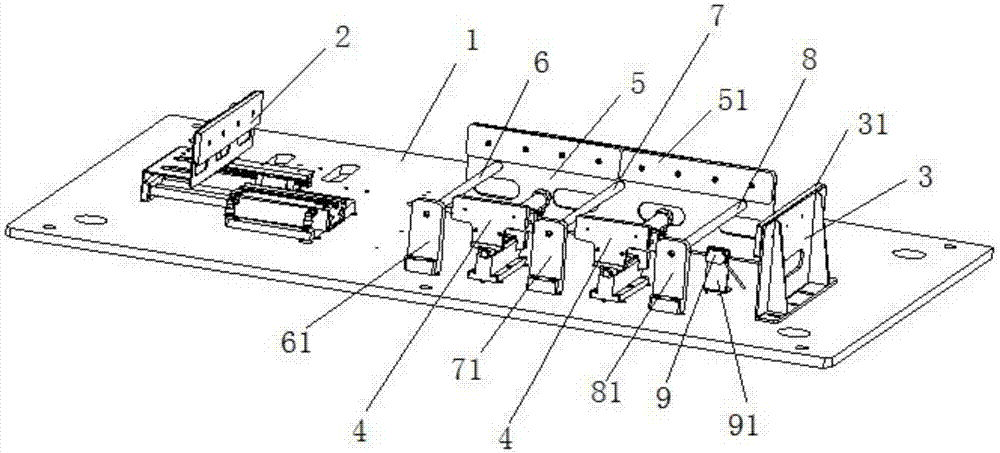

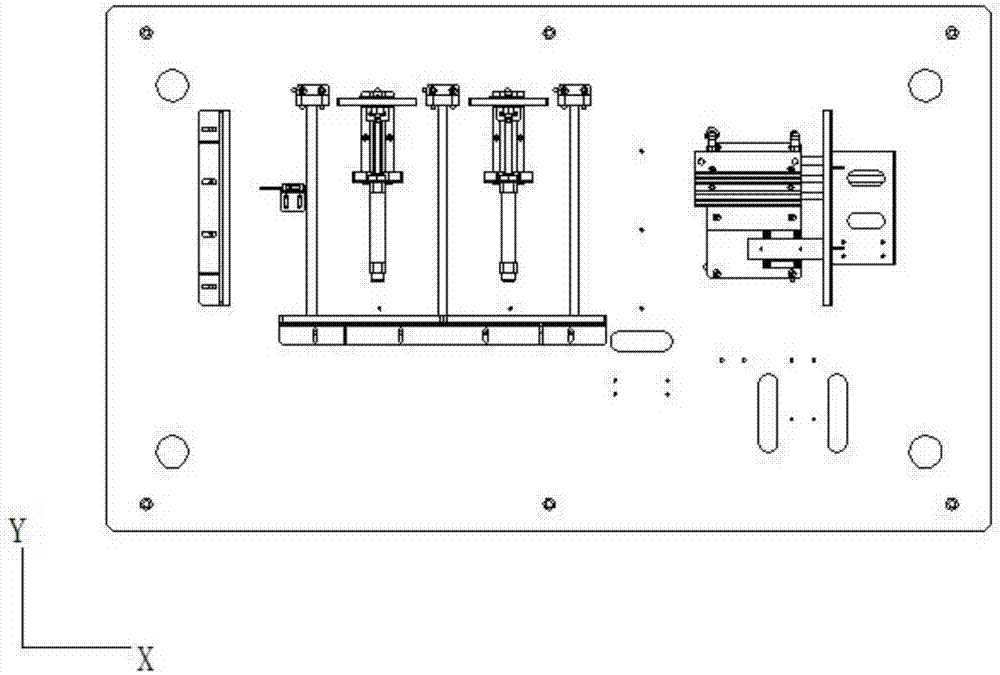

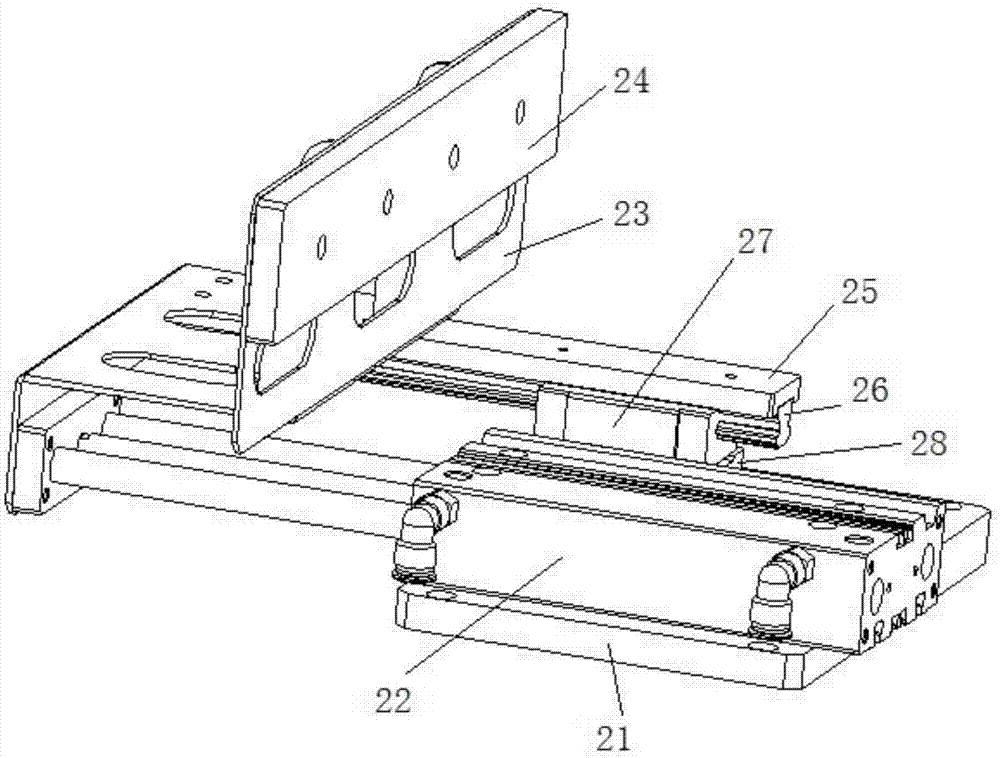

[0022] see Figure 1 to Figure 4 , the chassis secondary positioning device, including base plate 1, X-axis positioning assembly 2 installed on base plate 1, X-axis limiting plate 3, Y-axis positioning assembly 4, Y-axis limiting plate 5, and X-axis limiting plate 3 An X-axis limiting plate buffer pad 31 is provided, a Y-axis limiting plate buffer pad 51 is provided on the Y-axis limiting plate 5, the base plate 1 is rectangular, and the two adjacent sides of the base plate 1 are respectively the X axis and the Y axis, The X-axis positioning assembly 2 is arranged opposite to the X-axis limiting plate 3, the Y-axis positioning assembly 4 is arranged opposite to the Y-axis limiting plate 5, and the base plate 1 is also provided with a first support rod fixing seat 61 and a second support rod fixing seat 71 and the third support rod holder 81, the first support rod holder 61, the second support rod holder 71 and the third support rod holder 81 are respectively provided with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com