Printing nozzle

A technology for printing nozzles and nozzles, which is applied in the field of printer parts and components, and can solve problems such as the inability to adjust the type of raw materials, single color, and the inability to effectively print products of various colors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

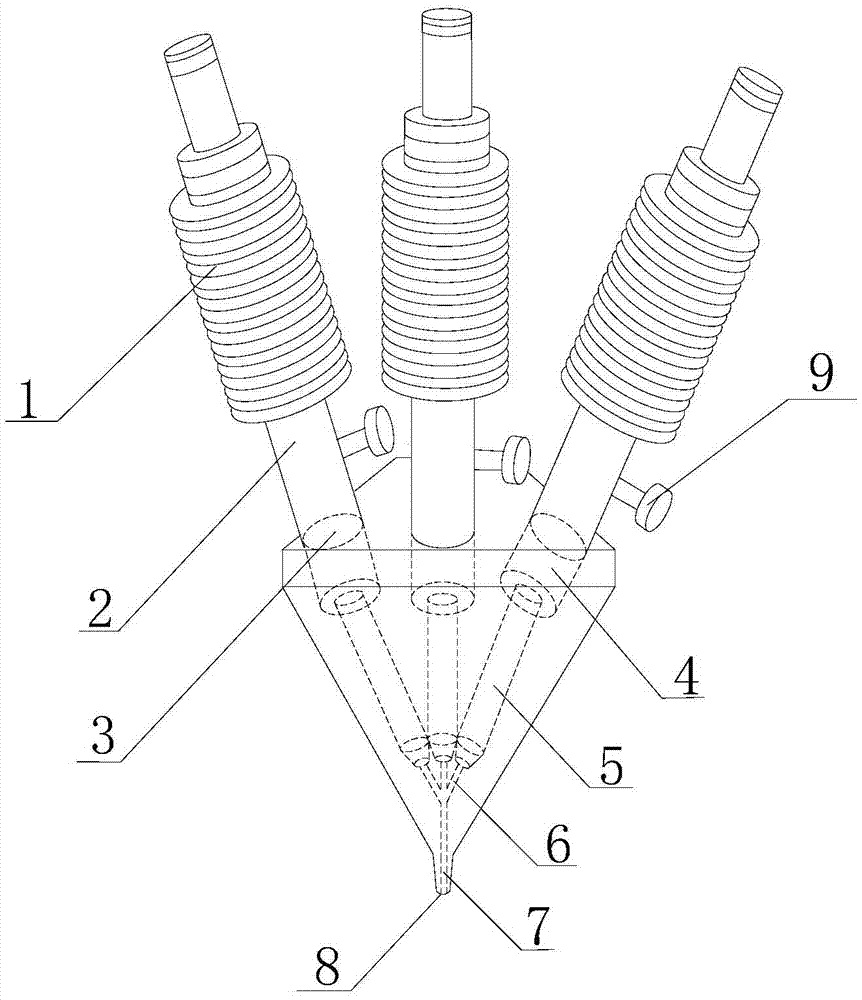

[0023] Such as figure 1 , the present invention provides a print nozzle, wherein the print nozzle includes: a heat dissipation pipe 1, a throat 2 and a nozzle connected in sequence from top to bottom, the throat 2 is provided with a heating device, and the nozzle It is an inverted and vertically arranged cone, and there are at least 3 channels inside the spray head, the opening 3 of the channel is located on the upper surface of the spray head, and the channels at least include sequentially connected from top to bottom with decreasing diameters. The fixed hole 4, the first connecting pipe 5 and the second connecting pipe 6, the inside of the spray head is also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com