Hydraulic booster for automobile braking

An automobile braking and hydraulic boosting technology, applied in the field of auto parts, can solve the problems of abnormal brake pedal shaking, poor driving comfort, and the brake pedal cannot produce a braking feeling, so as to improve driving comfort and avoid abnormal dithering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

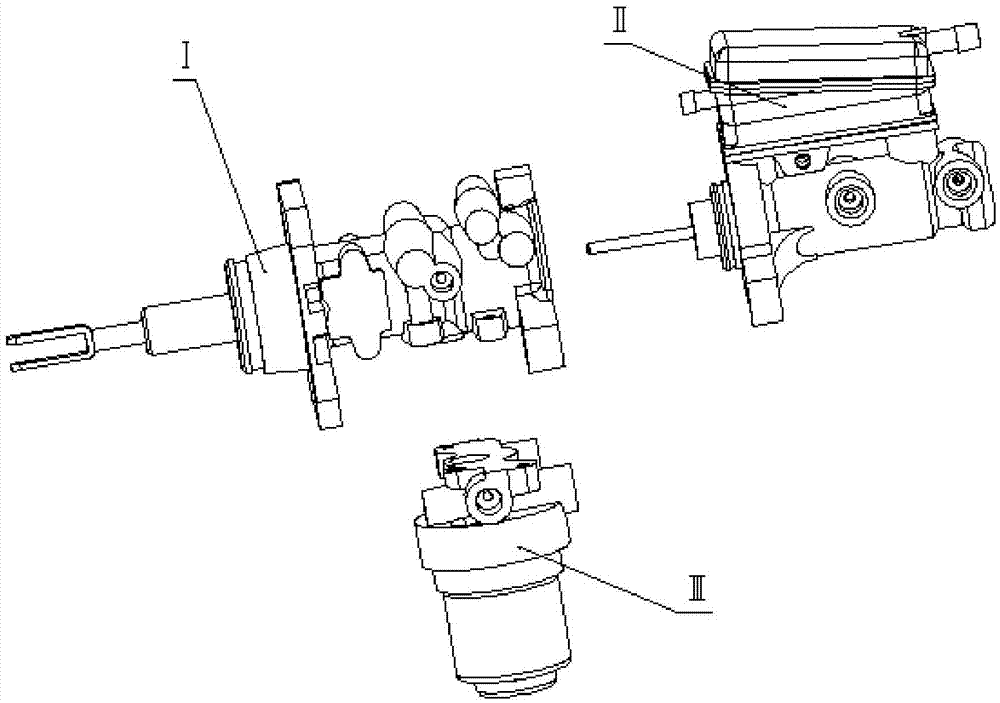

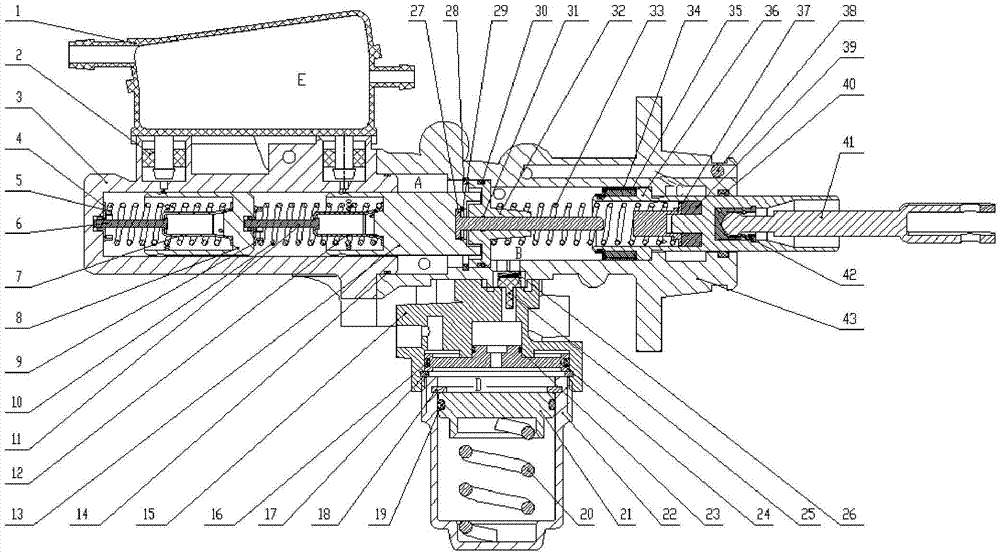

[0023] In electric vehicles and hybrid vehicles, an electronically controlled hydraulic power assist system is installed, and a hydraulic source is used instead of a vacuum source as a power source to implement driving assist actions. The system includes a hydraulic booster and a hydraulic control module.

[0024] The hydraulic control module is the pressure control part of the system, including the electronic control unit, increasing and decreasing solenoid valves, hydraulic sensors, motors, oil pumps, high-pressure accumulators, check valves, etc. Its function is to receive the CAN signal and braking signal of the whole vehicle, make a judgment on the braking condition, and according to the corresponding logic algorithm, control the action of the pressure increase and decrease valve, release the oil pressure in the high pressure accumulator, and enter the corresponding brake circuit . Finally, it acts on the hydraulic booster to generate braking force. Its motor and oil pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com