Barrel cover lifting mechanism for large stirrer

A technology of agitator and bucket lid, which is applied in the field of lifting mechanism of bucket lid for large agitator, which can solve the problems of safety hazard, trouble, heavy weight, etc., and achieve good lifting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

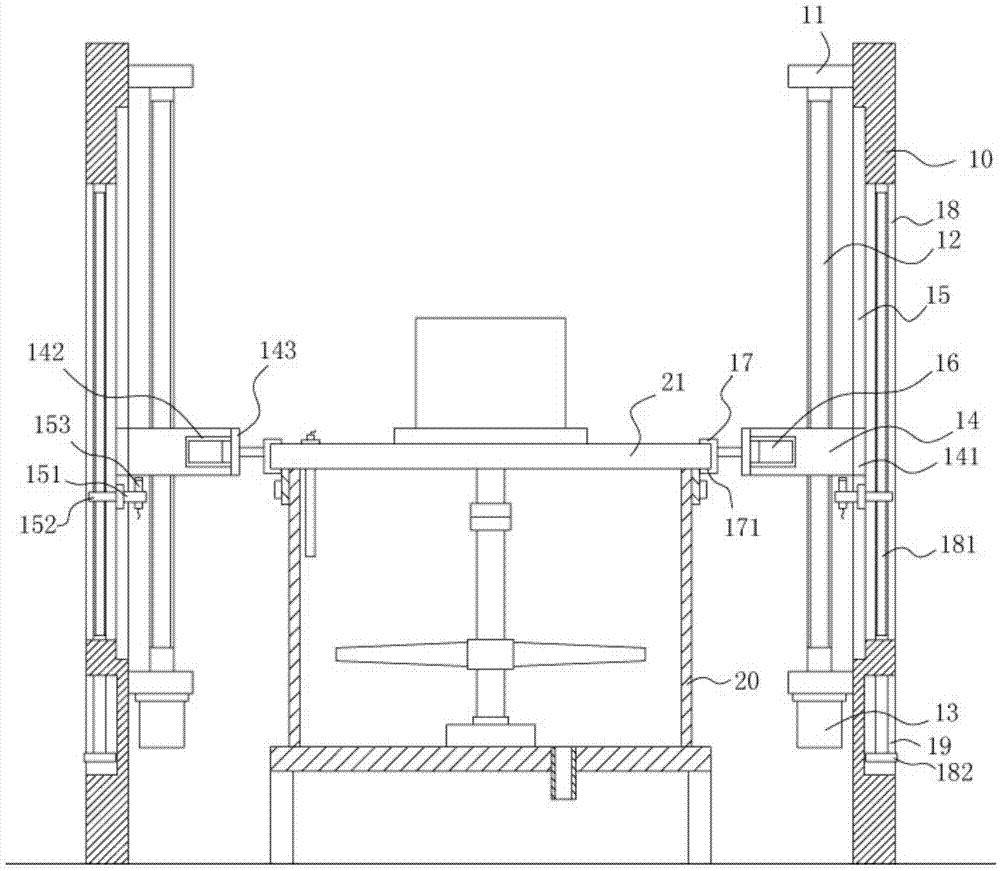

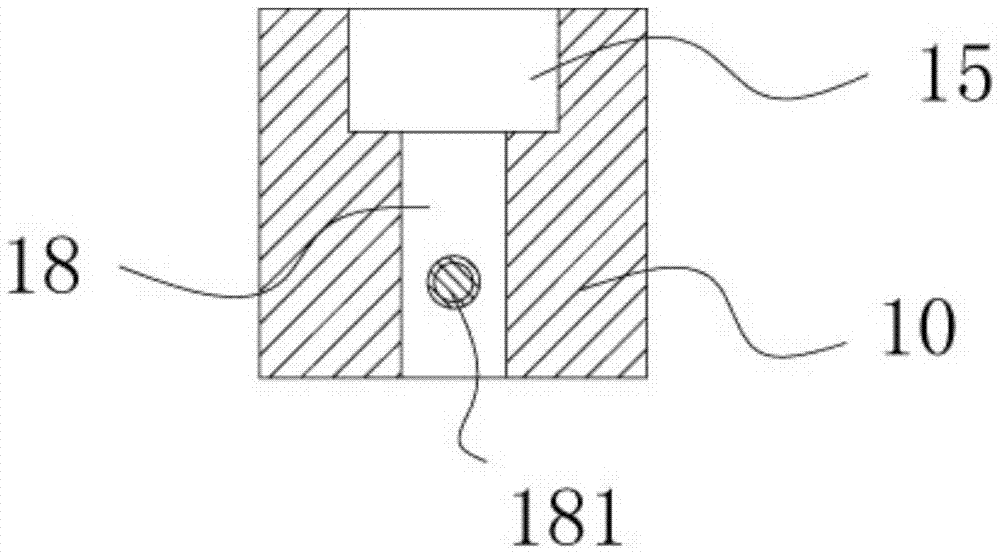

[0013] Example: see Figure 1 to Figure 2 As shown, a bucket lid lifting mechanism for a large-scale mixer includes two support plates 10, and the two support plates 10 are located on the ground on both sides of the mixer barrel 20, and the upper parts of the opposite walls of the two support plates 10 and The lower part is fixed with a connecting plate 11, the two ends of the adjusting screw 12 are hinged on the two connecting plates 11, the connecting plate 11 below is fixed with a drive motor 13, the output shaft of the drive motor 13 is a spline shaft, and the spline shaft is inserted into the sleeve In the spline hole that the lower end surface of the corresponding adjusting screw 12 has, the moving block 14 is screwed in the adjusting screw 12, and the side wall of the support plate 10 facing the adjusting screw 12 has a bar-shaped groove 15, and the moving block 14 There is a protruding part 141 on the top, and the protruding part 141 is inserted in the strip groove 15....

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap