Retaining device for effectively preventing lifting platform from falling

A technology of a stop device and a lifting platform, which is applied in the direction of the lifting device, etc., can solve the problems such as the inability to weld the brake guide rails.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way, and any changes or improvements based on the teaching of the present invention fall within the scope of protection of the present invention.

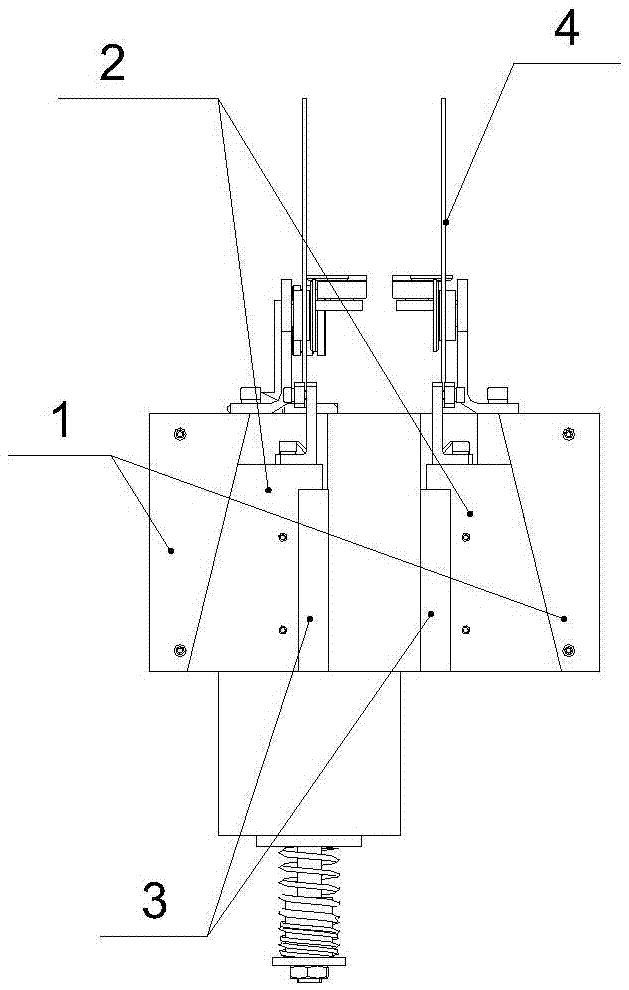

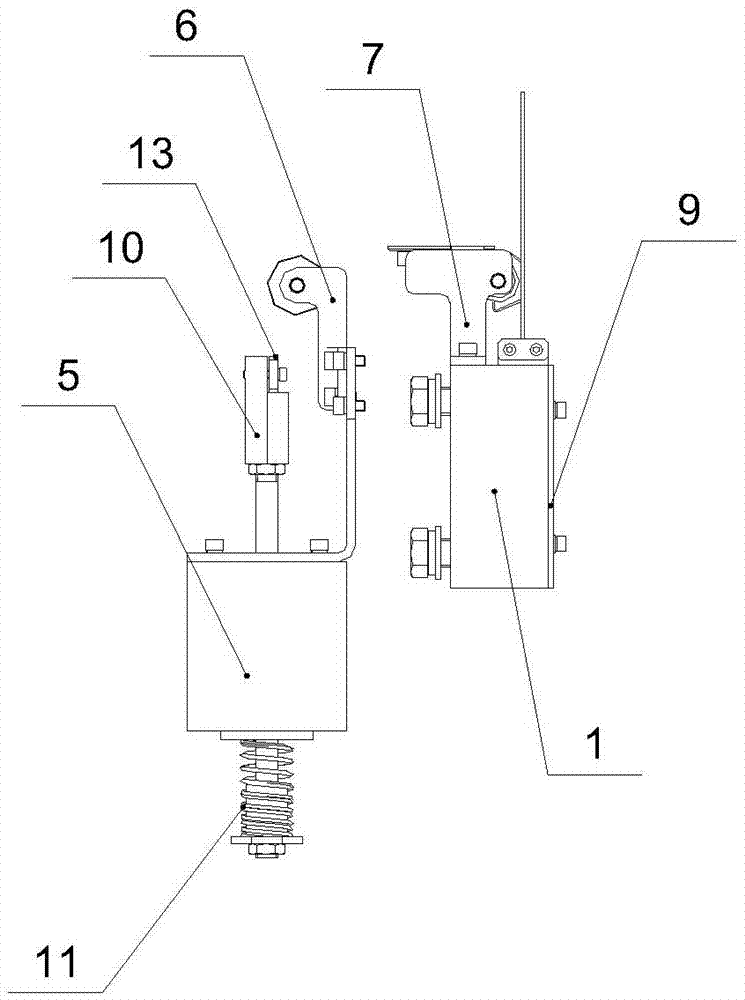

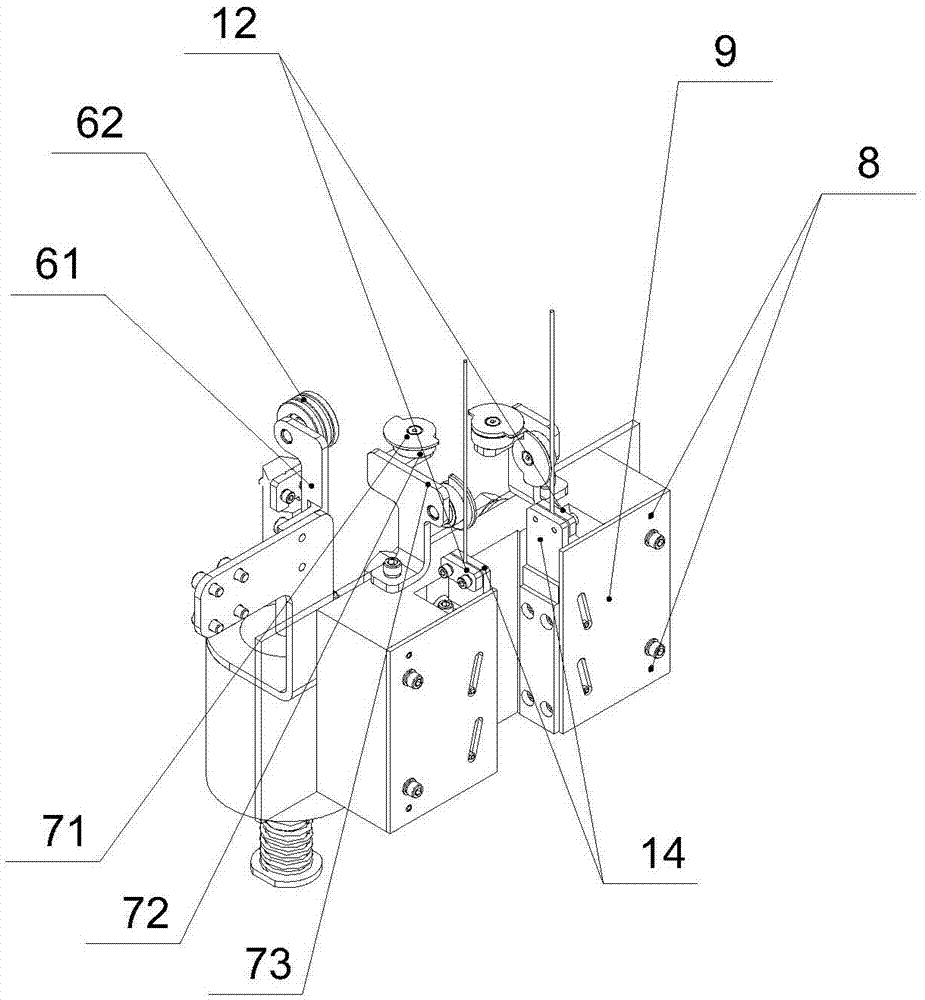

[0019] Such as Figure 1~3 As shown, a stop device for effectively preventing the lifting platform from falling, the present invention is characterized in that it includes two parts, the brake block 1 and the overspeed trigger device 5, and the wedge block 2 and the brake block 1 adopt a wedge with a slope. Wedging of joint surfaces, a pressure plate 9 is connected to the brake block 1, and a steel wire rope 4 is connected to the wedge block 2; wherein, the friction plate 3 is fixedly connected to the side of the wedge block 2, and the support block 14 is fixed to the wedge The top of the block 2; the top of the brake block 1 is provided with a guide wheel bracket II7; the press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com