Blue-green hollow monox photonic crystal structural color film and preparing method thereof

A technology of hollow silicon oxide and photonic crystals, which is applied in the field of blue-green hollow silicon oxide photonic crystal structural color thin films and its preparation, and can solve the problems of low reflection intensity of photonic crystals, limiting the application of hollow spherical photonic crystals, and small modulation of effective refractive index. , achieve bright colors, high saturation, and solve the effect of easy fading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for preparing a blue-green hollow silicon oxide photonic crystal structural color thin film, comprising the following steps:

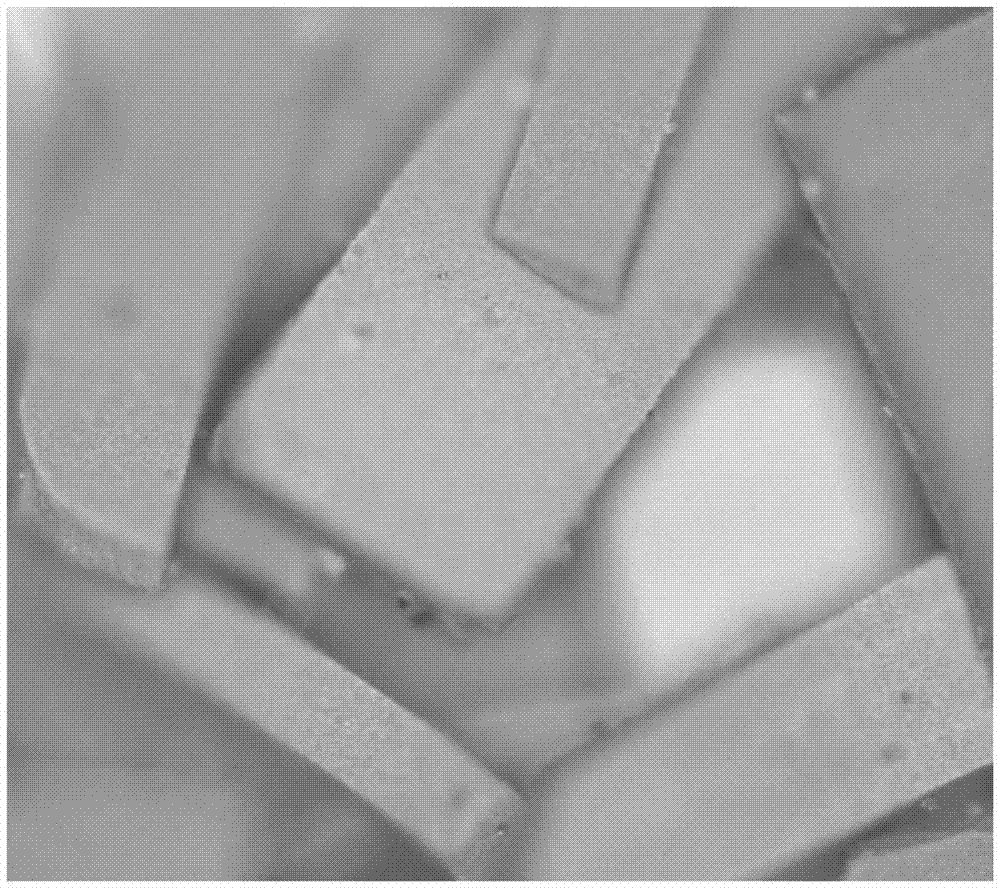

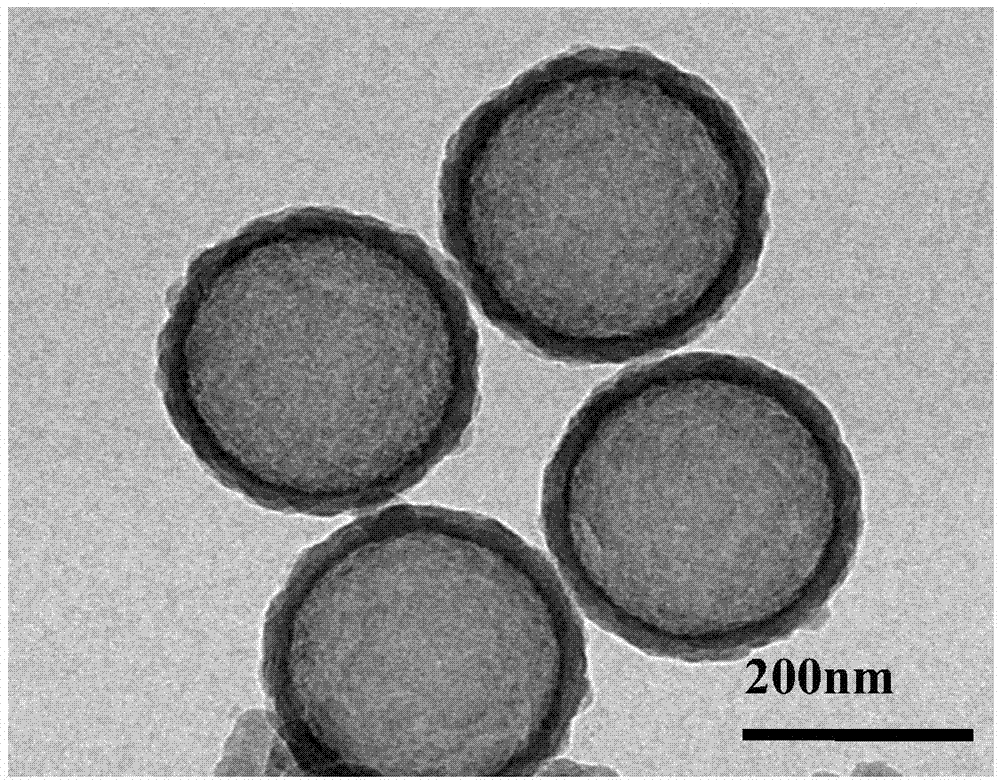

[0026] (1) According to the dosage ratio of 0.03g:30mL:2mL of polystyrene (PS) microsphere powder, ethanol and deionized water, weigh PS microsphere powder with a particle size of 240±5nm and ultrasonically disperse it in anhydrous In the mixture of ethanol and deionized water, after the dispersion is complete, add 0.3mL of ammonia water to the mixture according to the ratio of 0.3mL of ammonia water per 30mL of the mixture, stir magnetically at room temperature for 30min, and then quickly add 200uL orthosilicon to the reaction system Ethyl acetate was used as the silicon source, and the PSSiO 2 The core-shell microsphere has a diameter of 300±5nm and a shell thickness of 30±5nm.

[0027] (2) Accurately weigh step (1) to obtain PSSiO 2 Core-shell structure microspheres 0.1g, ultrasonically dispersed in 10mL of absolute ethanol, prepar...

Embodiment 2

[0032] A method for preparing a blue-green hollow silicon oxide photonic crystal structural color thin film, comprising the following steps:

[0033] (1) According to the dosage ratio of 0.03g:35mL:3mL of polystyrene (PS) microsphere powder, ethanol and deionized water, weigh PS microsphere powder with a particle size of 240±5nm and ultrasonically disperse it in anhydrous In the mixture of ethanol and deionized water, after the dispersion is complete, add 0.4mL of ammonia water to the mixture according to the ratio of 0.4mL of ammonia water per 35mL of the mixture, stir and mix by magnetic force at room temperature for 40min, then quickly add 230uL orthosilicon into the reaction system Ethyl acetate was used as a silicon source, and after 8 hours of magnetic stirring at room temperature, it was washed, centrifuged, and dried to obtain PSSiO 2 Core-shell structure microspheres, hollow silicon oxide core microspheres, the diameter of which is 300±5nm, and the thickness of the sh...

Embodiment 3

[0037] A method for preparing a blue-green hollow silicon oxide photonic crystal structural color thin film, comprising the following steps:

[0038](1) According to the dosage ratio of polystyrene (PS) microsphere powder, ethanol and deionized water according to the dosage ratio of 0.03g:40mL:4mL, the PS microsphere powder with a particle size of 240±5nm was ultrasonically dispersed in anhydrous In the mixture of ethanol and deionized water, after the dispersion is complete, add ammonia water to the mixture according to the ratio of 0.5mL ammonia water per 45ml mixture, stir and mix with magnetic force at room temperature for 50min, then quickly add 250uL orthosilicic acid into the reaction system Ethyl ester was used as a silicon source, and after 10 hours of magnetic stirring reaction at room temperature, it was washed, centrifuged, and dried to obtain PSSiO 2 Core-shell microspheres.

[0039] (2) Accurately weigh step (1) to obtain PSSiO 2 Core-shell structure microspher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com