An Efficient Vacuum Interrupter Brush Plating Equipment

A technology of vacuum interrupter and brush plating, applied in the direction of plating tanks, etc., can solve the problems of inconvenient use, low efficiency of brush plating, time-consuming and laborious, etc., and achieve the effects of efficiency improvement, high brush plating efficiency, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

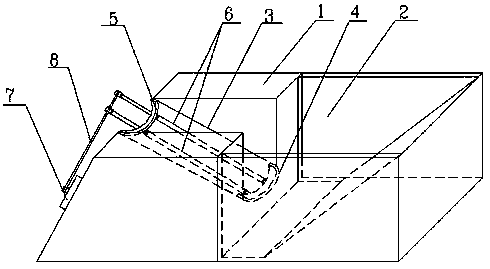

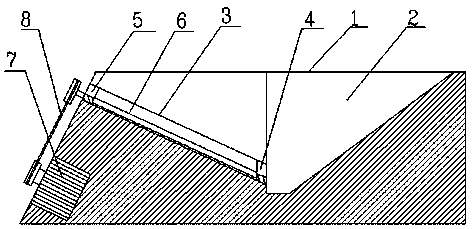

[0016] Embodiment of the present invention: a high-efficiency vacuum interrupter brush plating equipment, as attached Figure 1-2 As shown, housing 1 is included, and housing 1 is provided with upper and lower plating solution tank 2, and the tank wall on one side of plating solution tank 2 is provided with chute 3, and the lower end of chute 3 is connected with the The plating solution tank 2 is connected, the upper and lower ends of the chute 3 are respectively provided with an upper fixture 5 and a lower fixture 4, and two parallel rotating shafts 6 are arranged between the upper fixture 5 and the lower fixture 4.

[0017] As preferably, by designing the angle between the chute 3 and the horizontal plane to be 0°-90° (optimally, the angle between the chute 3 and the horizontal plane is 30°-45°), ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com