Heald lifting mechanism of jacquard

A technology of jacquard machine and arm plate, applied in the direction of jacquard machine, textile, textile and paper making, etc., can solve the problems of notch cracking, fracture, affecting the safe operation of the jacquard machine, etc., to achieve the effect of eliminating stress concentration and meeting the requirements of lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

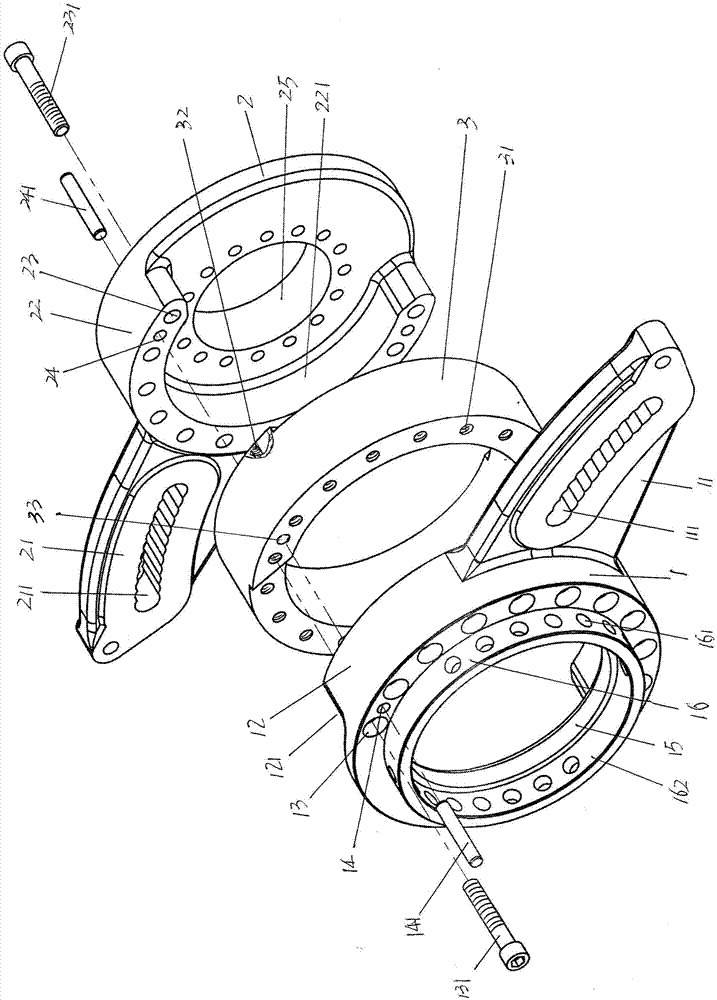

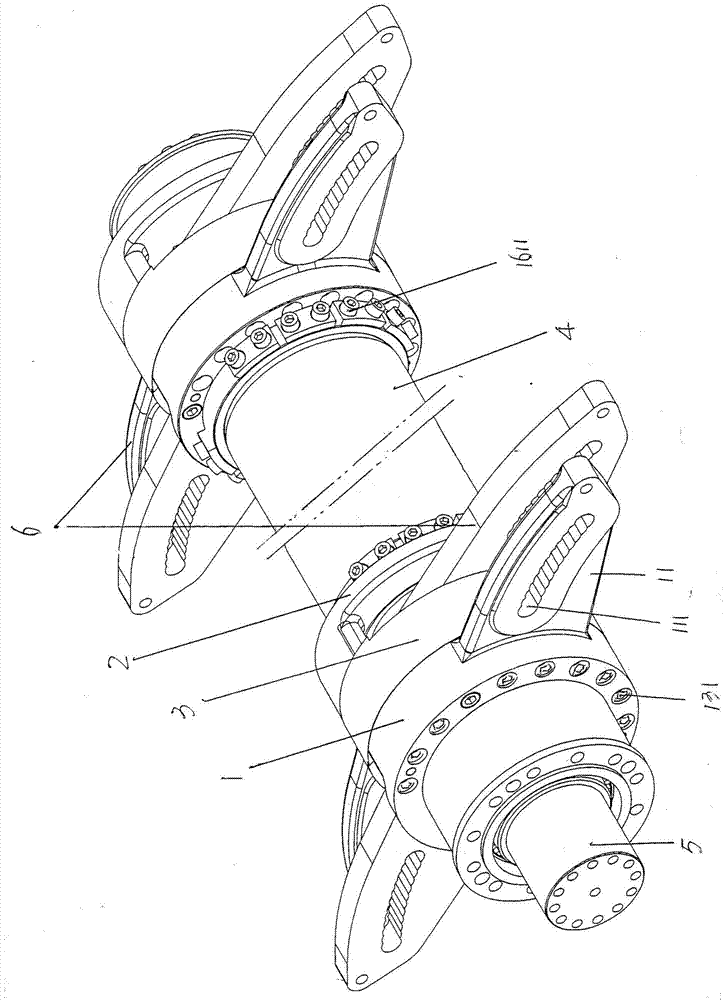

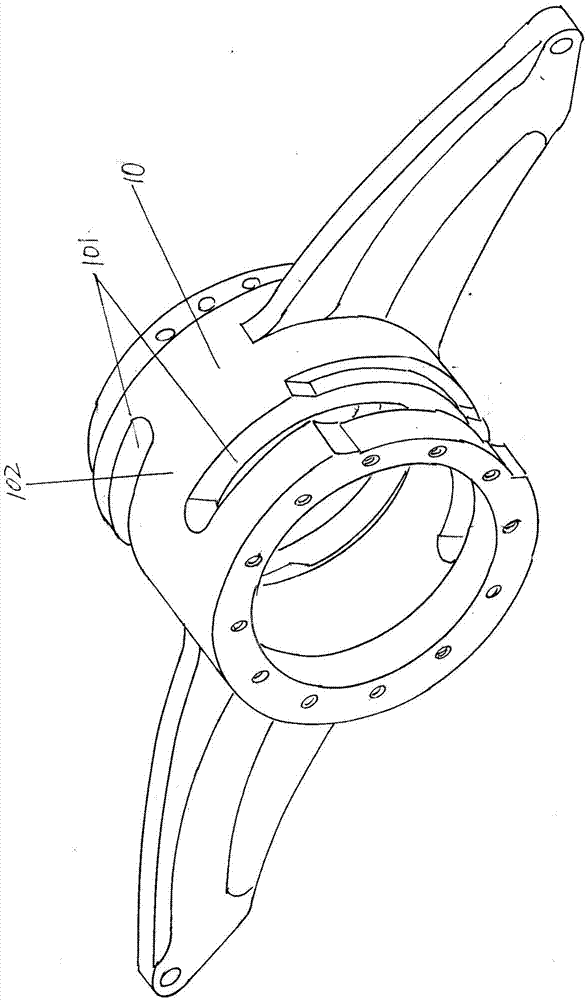

[0018] See figure 1 , provides a left outer swing arm disc 1, a right outer swing arm disc 2 and a left outer swing arm disc 1 and a right outer swing arm disc 2 that belong to the structural system of the heald lifting mechanism of the jacquard machine of the present invention. The partition plate 3, the left outer swing arm plate 1 and the left side of the spacer plate 3 are fixed on the left outer swing arm plate 1 and located on the front side of the left outer swing arm plate 1 so as to be perpendicular to the left outer swing arm plate 1 A left outer swing arm 11 is fixed, and the right outer swing arm plate 2 and the right side of the spacer 3 are fixed on the right outer swing arm plate 2 and positioned at the rear side of the right outer swing arm plate 2 so as to be perpendicular to the right outer swing arm plate The state of 2 has a right outer swing arm 21.

[0019] A left outer swing arm disc arc-shaped protrusion 12 is formed on the side of the left outer swin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap