Bridge with bracket tension and compression transfer beam and construction method of bridge

A construction method and a technology of compression conversion, which is applied to bridges equipped with support tension-compression conversion beams and their construction fields, which can solve the problems of high price, small tension, and easy damage, so as to enhance the tensile bearing capacity and reduce construction costs , cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

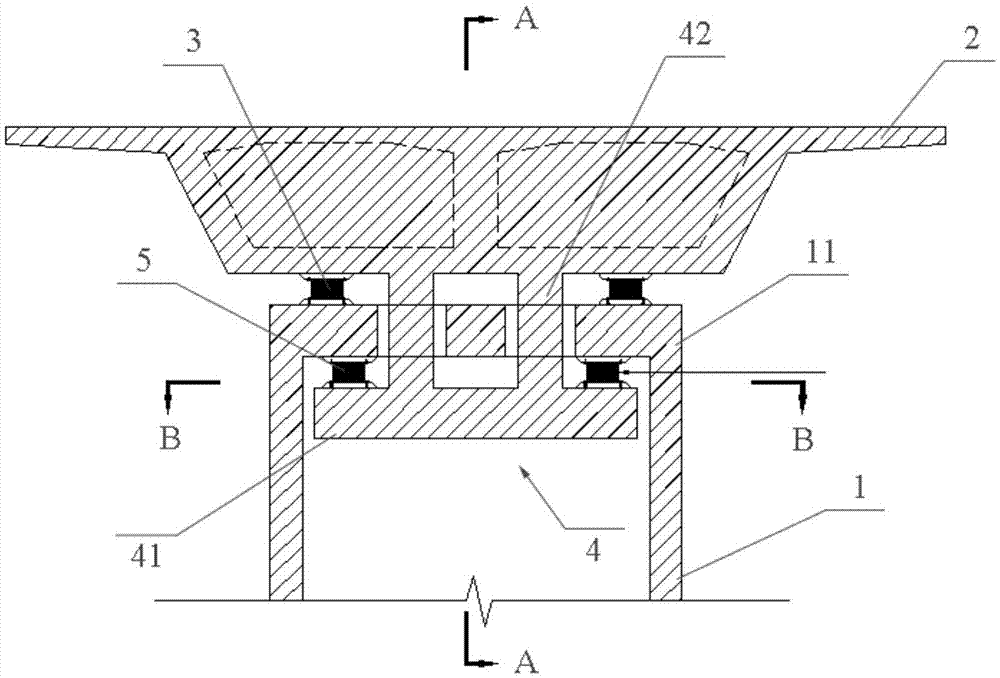

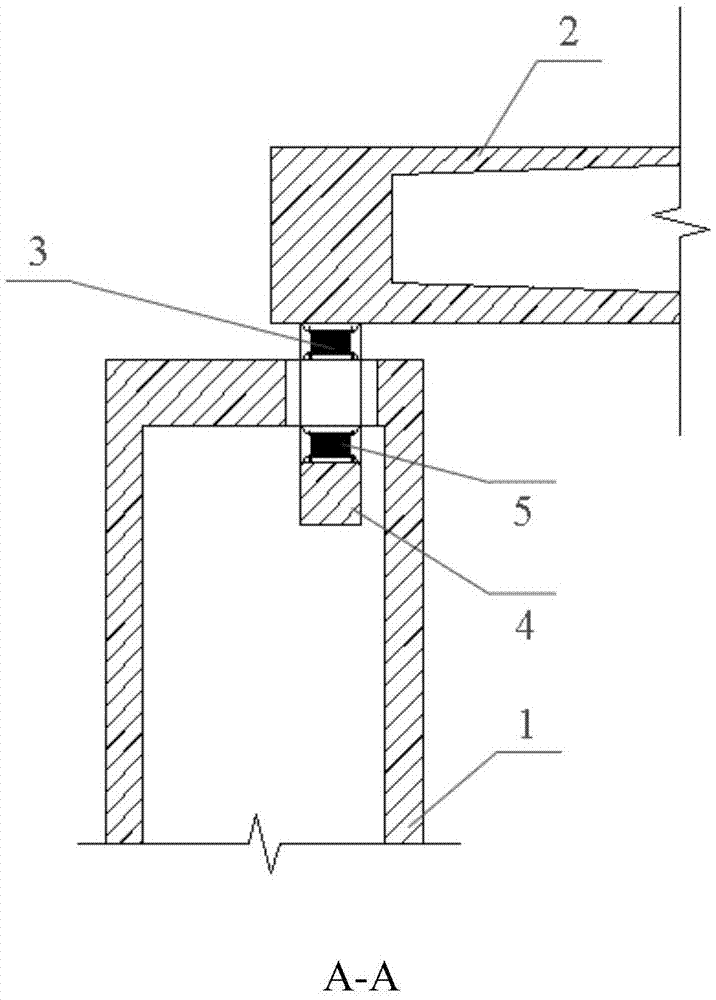

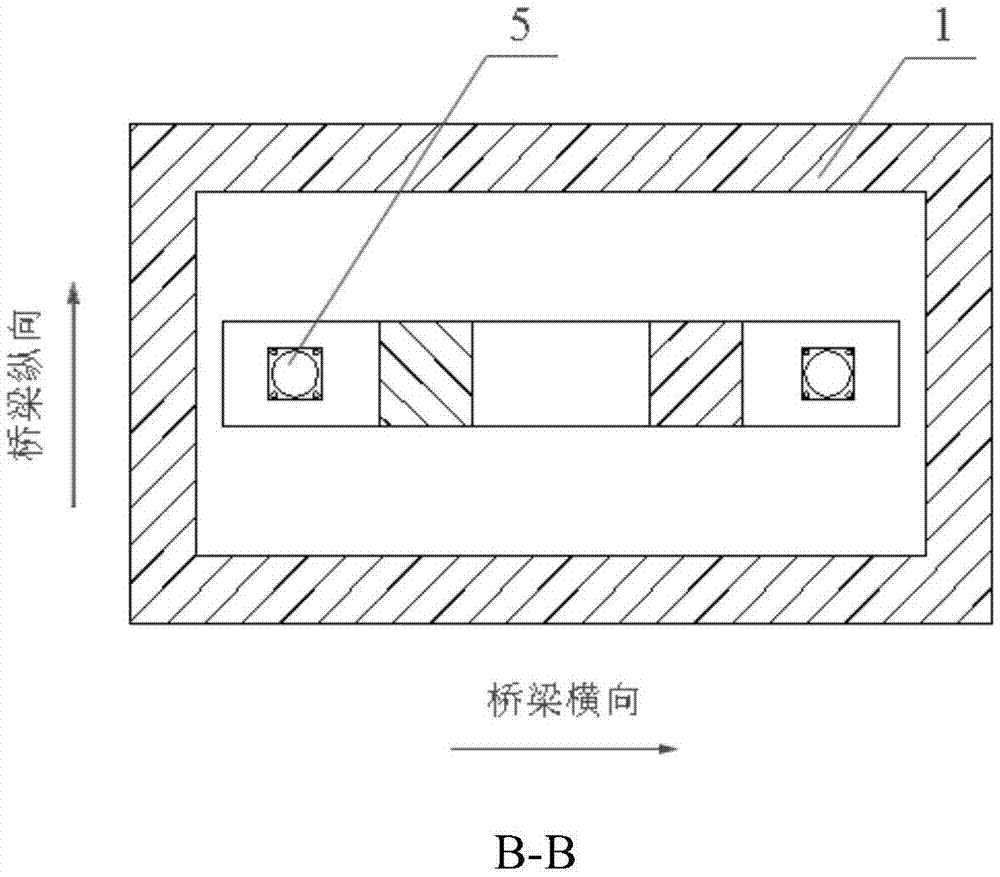

[0027] see figure 1 As shown, the present invention provides a bridge with support tension-compression conversion beams, which includes a plurality of hollow thin-walled piers 1, a main beam 2, an upper support 3, a support tension-compression conversion beam 4 and a lower support 5 .

[0028] The number of hollow thin-walled piers 1 can be reasonably determined according to the span of the bridge. There is a roof 11 on it, the main beam 2 is arranged on the roof 11, and a row of upper supports 3 is arranged between the bottom of the main beam 2 and the roof 11. There are two upper supports 3 in the invention, which are arranged symmetrically along the transverse direction of the bridge, and are used to support the main girder 2 .

[0029] The support tension-compression conversion beam 4 includes a beam 41 and a vertical beam 42 , wherein the beam 41 is em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com