Water-retaining construction technology for locked steel pipe piles

A construction technology, steel pipe pile technology, applied in the direction of infrastructure engineering, construction, etc., can solve problems such as constraints, and achieve excellent water stop, high construction efficiency, and good water stop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail in conjunction with a certain bridge engineering project using lock steel pipe pile cofferdam waterstop construction as an example.

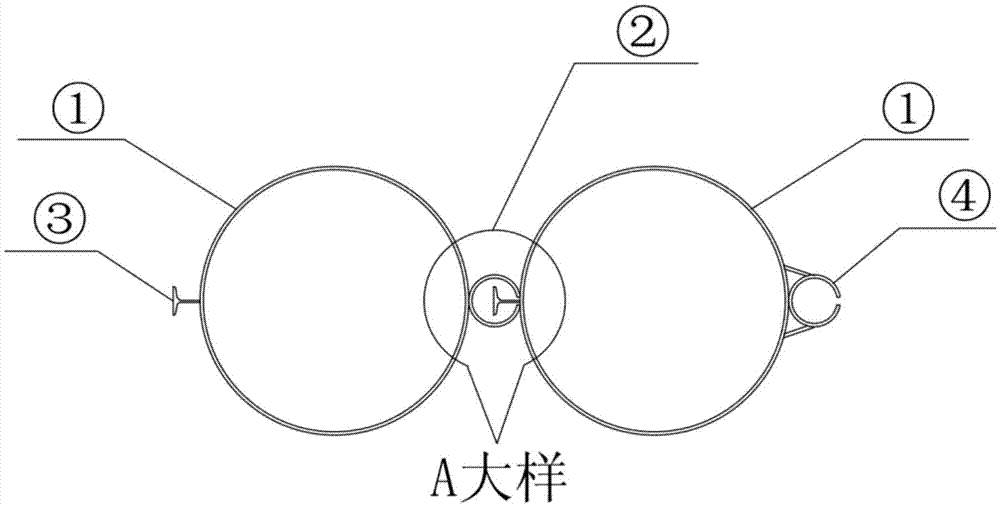

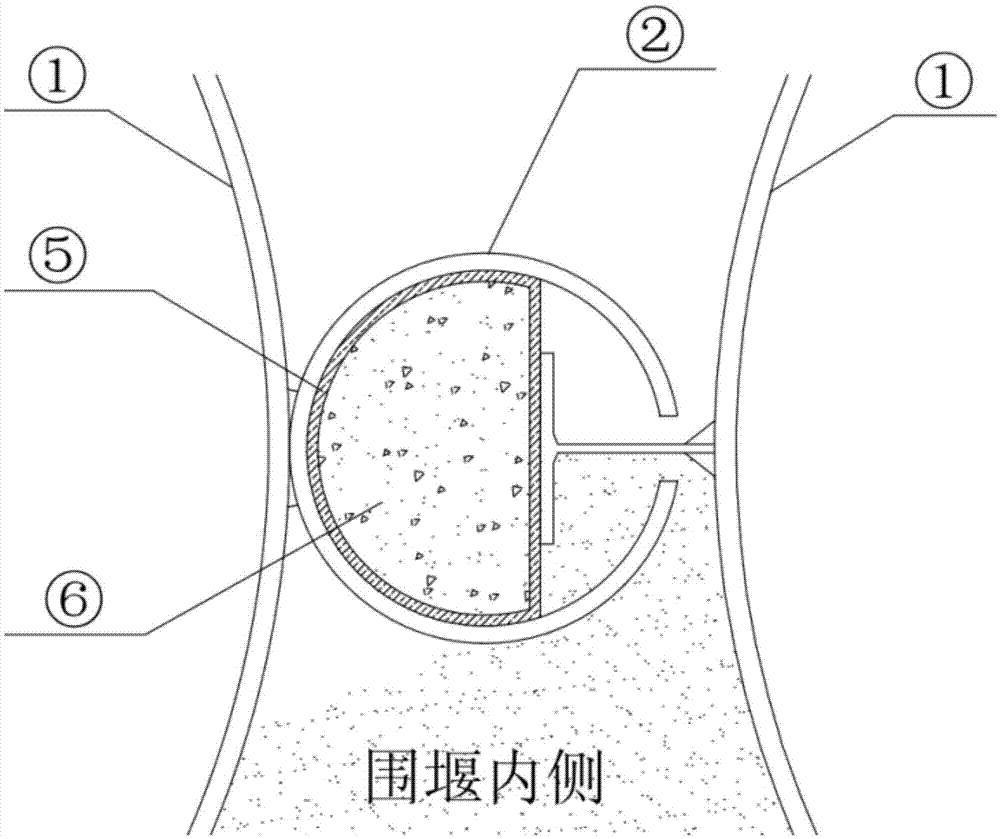

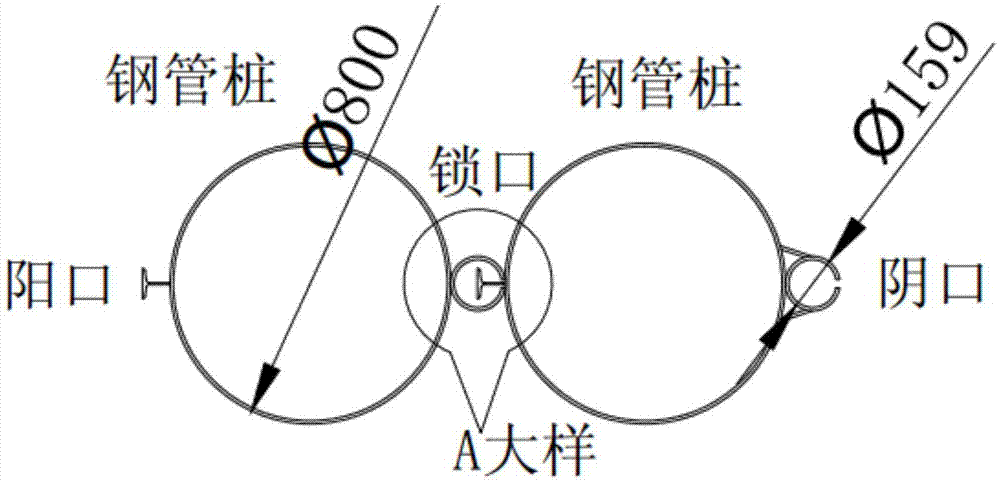

[0031] The bridge auxiliary pier cap is 37m long, 10.5m wide and 4m high, and the total square capacity of the cap is 1372m 3 , Locked steel pipe piles are used as water-stop cofferdams during construction. The water-stopping construction process of lock steel pipe piles is as follows: design and process TC type lock steel pipe piles → insert and drive lock steel pipe piles → lock cleaning → insert waterproof cloth belt and grouting pipe into the lock → adjust low strength and high strength Mortar→mortar injected into the lock→health preservation

[0032] 1. During construction, design the lock as a TC-type lock for insertion and punching. The steel pipe adopts a diameter of Φ800*10mm, the T-shaped male port of the lock is cut in half with I16 I-shaped steel, and the C-shaped fem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com