Wide-range FRP (fiber reinforced plastic) embedded steel wire composite optical fiber smart rebar and preparation method thereof

A composite optical fiber and large-scale technology, which is applied in the direction of measuring, measuring force, and measuring devices through the measurement of the change in optical properties of materials when they are stressed, can solve the problem of limited ultimate strain, limit the application of smart tendons, and cannot meet a large number of applications. Process monitoring and other issues to achieve the effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0040] In order to achieve the purpose of the present invention, in some embodiments of the large-scale FRP embedded steel wire composite optical fiber smart rib and its preparation method,

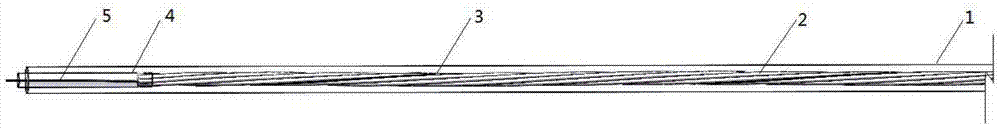

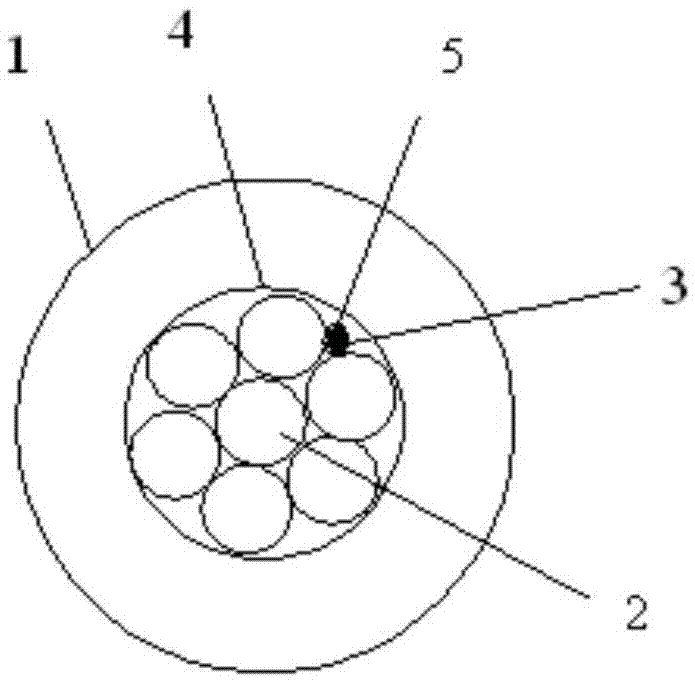

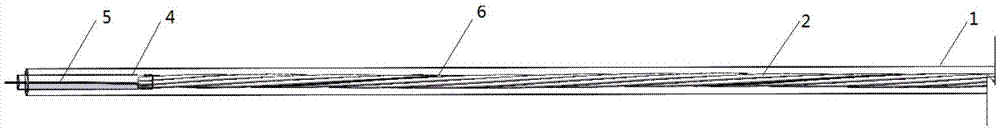

[0041] Such as Figure 1-4 As shown, the large-scale FRP embedded steel wire composite optical fiber smart tendon includes: steel strand 2, optical fiber 3 or optical fiber grating 6, and a wrapping layer 1 made of fiber-reinforced composite material. In the following embodiments, the large-scale FRP embedded steel wire composite optical fiber smart tendon is referred to as smart tendon.

[0042] The steel strand 2 is arranged in the center of the smart tendon, and the optical fiber 3 or the fiber grating 6 is spirally wound on the steel strand 2 along the length direction of the steel strand 2, and the outer side of the optical fiber 3 or the fiber Bra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com