Corrugated tube stop valve

A bellows stop valve and bellows technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of large valve core, no bellows rupture alarm function, medium erosion and other potential safety hazards, so as to eliminate potential safety hazards , to ensure adjustability, to improve the effect of working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

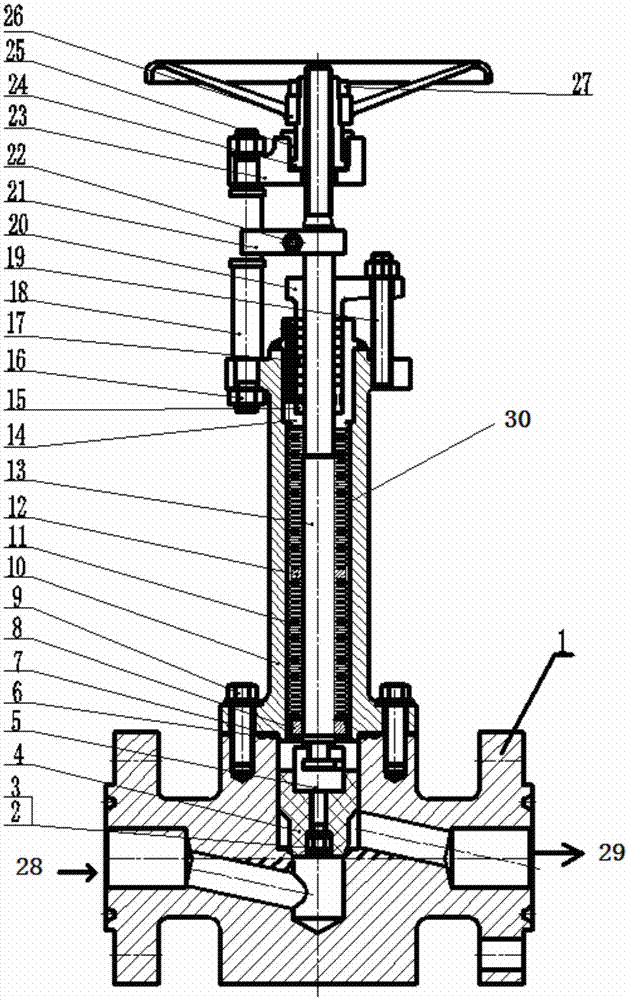

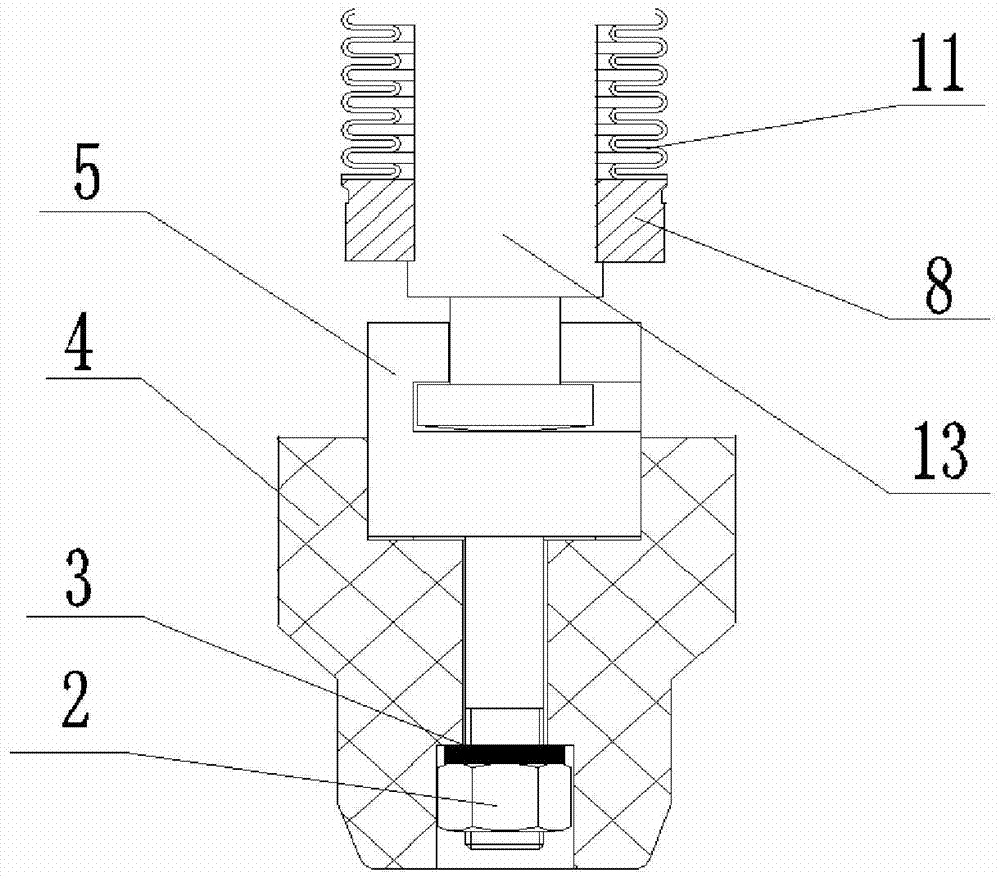

[0023] Such as figure 1 As shown, the bellows stop valve of the present invention is a low-in and high-out valve, including a handwheel 16, a valve stem 3, a packing assembly, a bellows assembly, a valve cover 10, a valve body 1 and The spool 4 and the valve body 1 are provided with an inlet 28, a vertical hole and an outlet 29 connected to each other. Under the rotation of the hand wheel 16, the valve stem 3 drives the spool 4 to move up and down in the vertical hole to realize the inlet 28. and the conduction or closure of the outlet 29, in order to ensure the tight sealing of the valve, the valve stem of the valve adopts two seals of the bellows assembly and the packing.

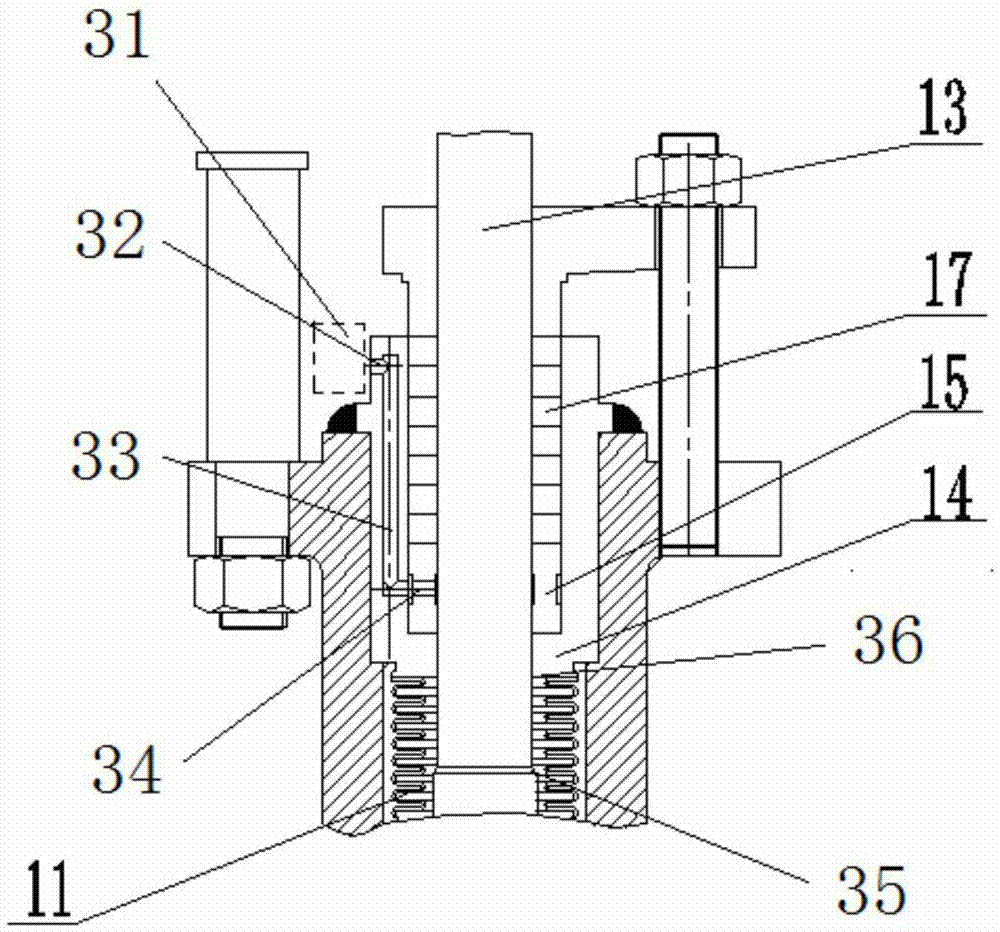

[0024] Such as figure 2 As shown, the packing assembly includes a stuffing box 14, a stuffing ring 15, a stuffing 17, and a packing gland 20. The stuffing 17 is installed in the stuffing box 14, and the stuffing 17 is in close contact with the valve stem 13 through the stuffing gland 20, so that the stu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com