Heat insulation structure of high-temperature valve

A valve and high-temperature technology, which is applied in the field of high-temperature valve heat insulation structure, can solve the problems of valve drive device loss, thermal aging of non-metallic materials, etc., and achieve the effects of ensuring performance reliability and life, reducing heat radiation, and reducing heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

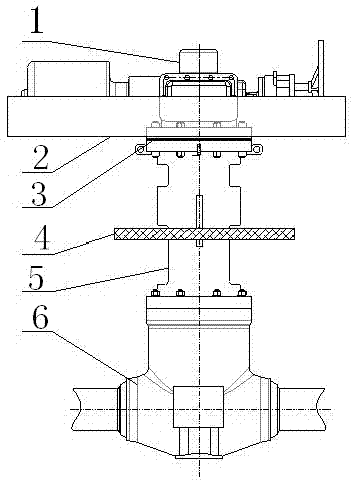

[0015] High temperature valve heat insulation structure: including drive device 1, valve stem, valve body 6, valve core, bracket 5, valve cover, first radiation protection plate 2 and second radiation protection plate 4, valve cover is set on the upper end of valve body 6, valve A valve core is set inside the body 6, the driving device 1 is connected to the valve core through a valve stem, a bracket 5 is arranged outside the valve stem, the top end of the bracket 5 is connected to the driving device 1, the bottom end of the bracket 5 is set on the valve cover, and the first radiation protection plate 2 is set Below the drive device 1 and above the support 5 , a second radiation shield 4 is arranged on the support 5 . The first anti-radiation board 2 and the second anti-radiation board 4 are high-temperature-resistant fiberboards, and an aluminum alloy framework is arranged inside the high-temperature-resistant fiberboards. The top of the bracket 5 is provided with an insulatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com