Refrigeration device

A refrigeration device and liquid refrigerant technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of reducing system capacity and energy efficiency, improve capacity and energy efficiency, increase suction specific volume, and solve system energy efficiency reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

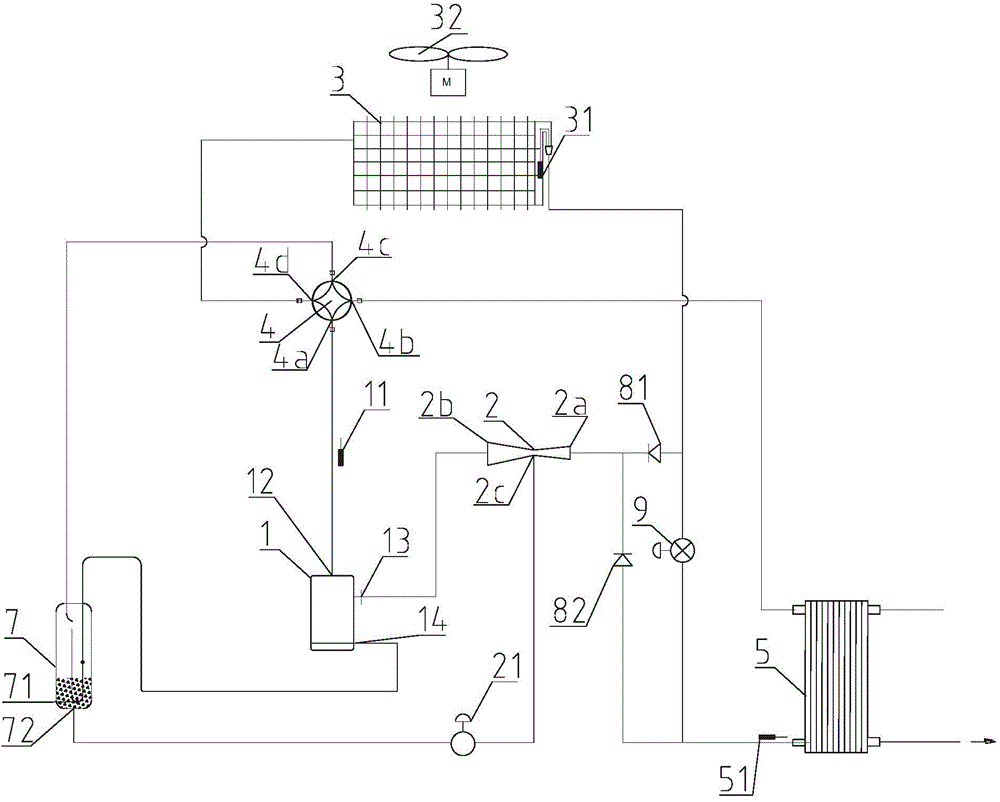

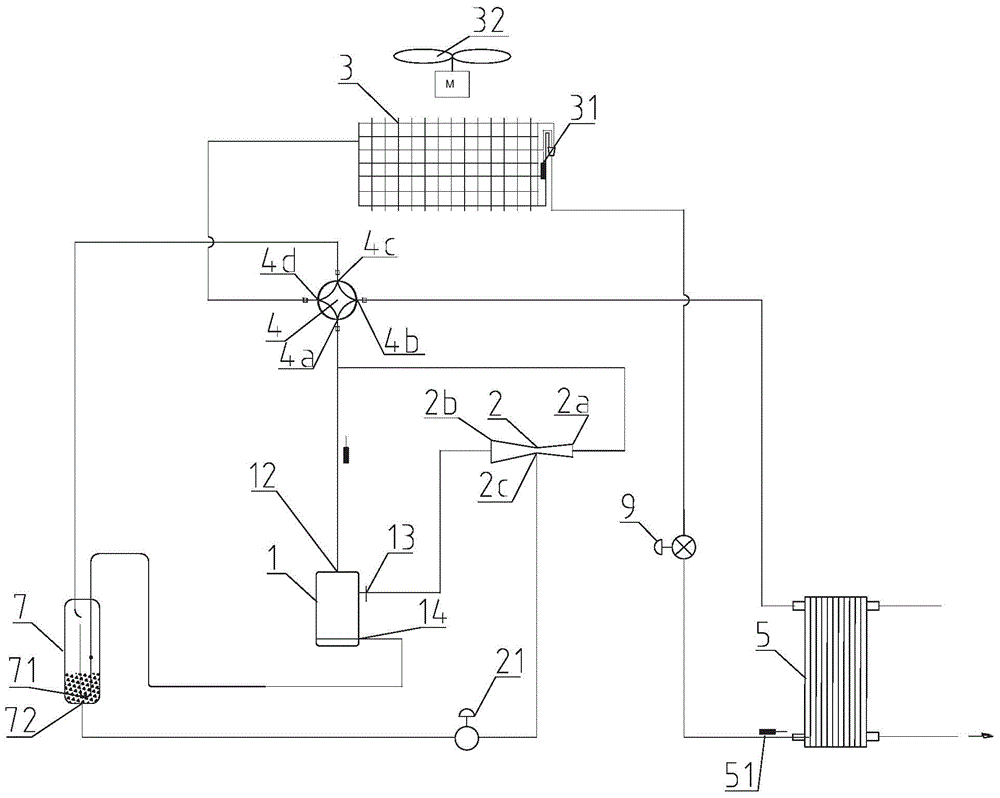

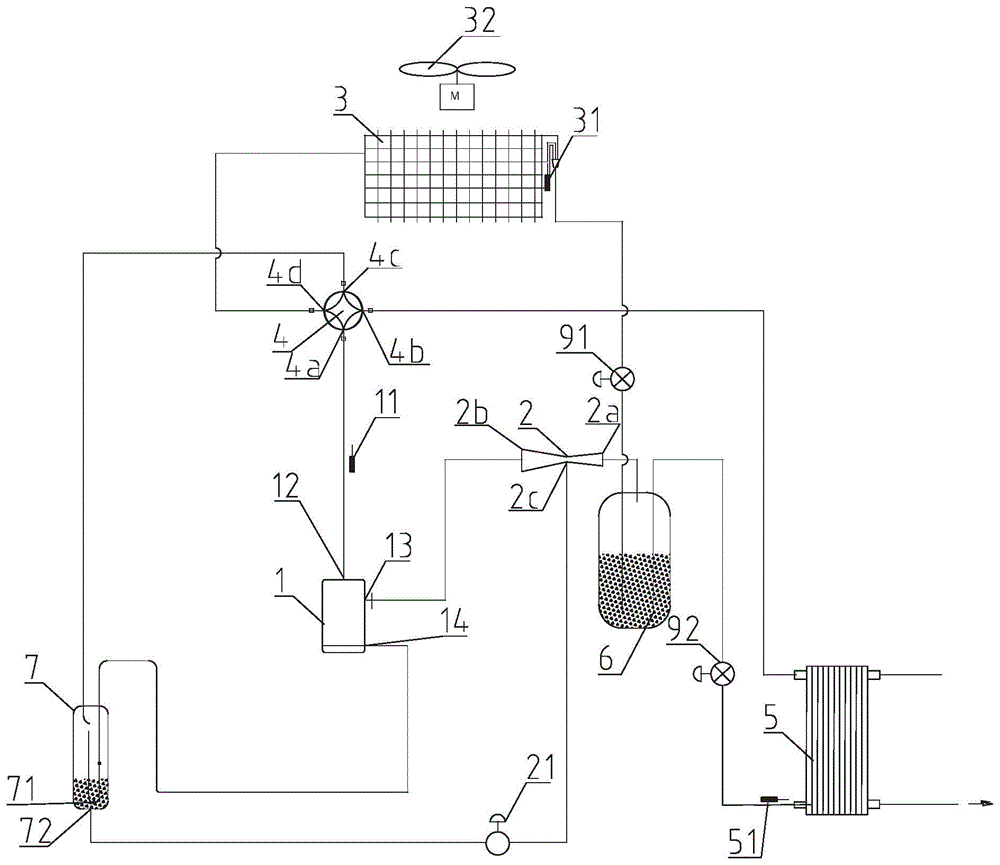

[0032] Preferably, as figure 1 In the shown first embodiment of the present invention, the refrigeration device with ejector is EVI ejector economizer heat pump system, and the gas-liquid separation equipment is gas-liquid separator 7, which is set at the bottom of gas-liquid separator 7 There is a bottom port 72 , and the low-pressure port 2c of the ejector 2 is connected to the bottom port 72 of the gas-liquid separator 7 via the solenoid valve 21 . In the illustrated embodiment, a compressor 1 , an air source heat exchanger 3 , a user side heat exchanger 5 , a gas-liquid separator 7 , an ejector 2 and an expansion valve 9 are included. A first temperature sensor 11 is provided on the air outlet pipeline of the compressor 1 ; a second temperature sensor 31 and a fan 32 are provided on the air source heat exchanger 3 . The solenoid valve 21 is provided between the low-pressure port 2c and the bottom port 72 . The solenoid valve 21 is used to control the switch of the ejecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com