Measuring scale and measuring method for automatically-centralized level gauge

A technology for measuring rulers and leveling rods, applied in height/horizontal measurement, measuring devices, measuring inclination, etc., can solve the problems of high labor intensity, low measurement efficiency, and large measurement error, so as to reduce labor intensity and low input cost , the effect of workload reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

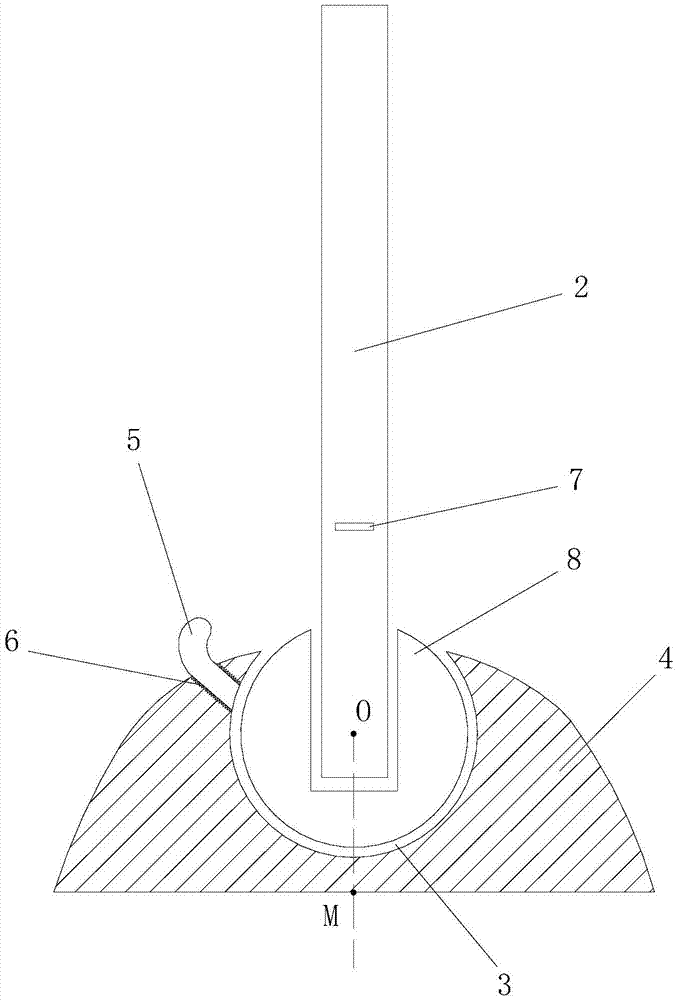

[0047] Such as figure 1 The shown measuring scale of a self-erecting level includes a base 4, a leveling staff 2 mounted on the base 4 and used in conjunction with the leveling instrument 1, and a leveling staff fixed on the leveling staff 2 and measuring the verticality of the leveling staff 2. A level 7, the level 7 is located on the central axis of the leveling staff 2 and is arranged vertically to the leveling staff 2 . The leveling rod 2 is located above the base 4 and its bottom is installed on the base 4 through a ball joint. The bottom of the leveling rod 2 is provided with a ball joint head 8, and the ball joint head 8 is located at the inner middle part of the base 4. The base 4 is a ball joint base for the installation of the ball joint head 8, and the upper part of the ball joint base is provided with a spherical groove 3 for the ball joint head 8 to snap into. Lock and fix.

[0048] In this embodiment, the level 7 is arranged on the body of the leveling staff 2 ...

Embodiment 2

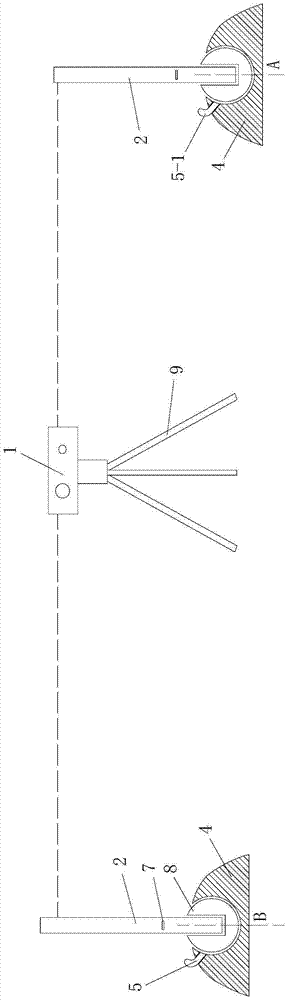

[0091] In this embodiment, the structure and connection relationship of the measuring scale of the automatic leveling instrument used are the same as those in Embodiment 1.

[0092] In this embodiment, the method for leveling using the measuring scale adopted is different from Embodiment 1 in that: the bottom surface of the base 4 in step one is a circular plane and the radius of the bottom surface is r; step three When carrying out leveling measurement in the center, first measure according to the conventional leveling method, and use the leveling instrument 1 to read the readings of the leveling staff 2 in the two measuring scales respectively, wherein the leveling in the measuring scale installed on the known elevation point A is The reading on scale 2 is denoted as H A , the reading of the leveling staff 2 in the measuring scale installed on the point B to be measured is denoted as H B ; After that, according to the formula H AB =H A '-H B '(3), calculate the elevation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com