Synchronization measurement device and method thereof

A technology of measuring devices and measuring methods, which is applied in the direction of measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as large measurement errors, reduce labor force, improve measurement accuracy, and reduce measurement errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

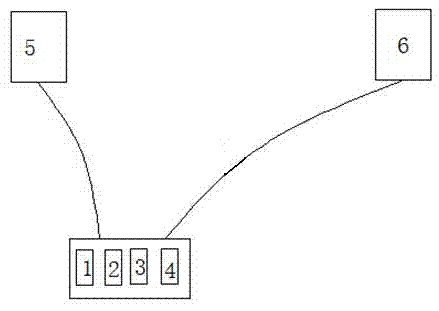

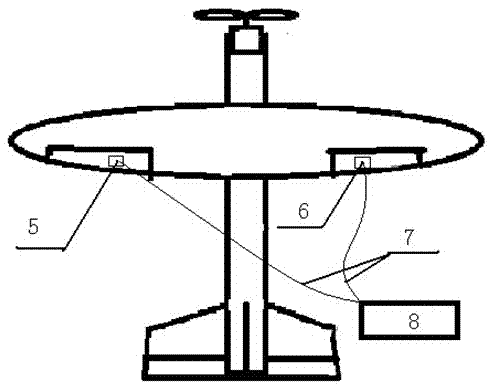

[0009] Such as figure 1 As shown, the synchronization measuring device includes a shock sensor 5 , a shock sensor 6 , a timer 1 , a timer 2 , a timer 3 , a timer 4 , and a wire 7 . The shock sensor 5 is connected to the timer 1 and the timer 2 by wires, and the shock sensor 6 is connected to the timer 3 and the timer 4 by wires. When measuring the movement synchronicity of the moving parts, fix the shock sensor 6 and the shock sensor 5 on the two moving parts respectively, adjust the four timers to zero and start timing. The staff manipulates the movable parts to move. When the movable parts start to move, the timer 1 receives the signal of the vibration sensor 5 to stop timing, and the timer 3 receives the signal of the vibration sensor 6 to stop timing. After the movement of the moving parts ends, the timer 2 receives the signal of the vibration sensor 5 to stop timing, and the timer 4 receives the signal of the vibration sensor 6 to stop timing. The difference between tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com