Tank-type breaker and moving-end air retaining device thereof

A circuit breaker and moving end technology, applied in high-voltage air circuit breakers, circuits, electrical components, etc., can solve the problems of hot gas being sprayed on the inner wall of the tank and the gas blocking effect is not ideal, so as to avoid failure of breaking and speed up cooling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

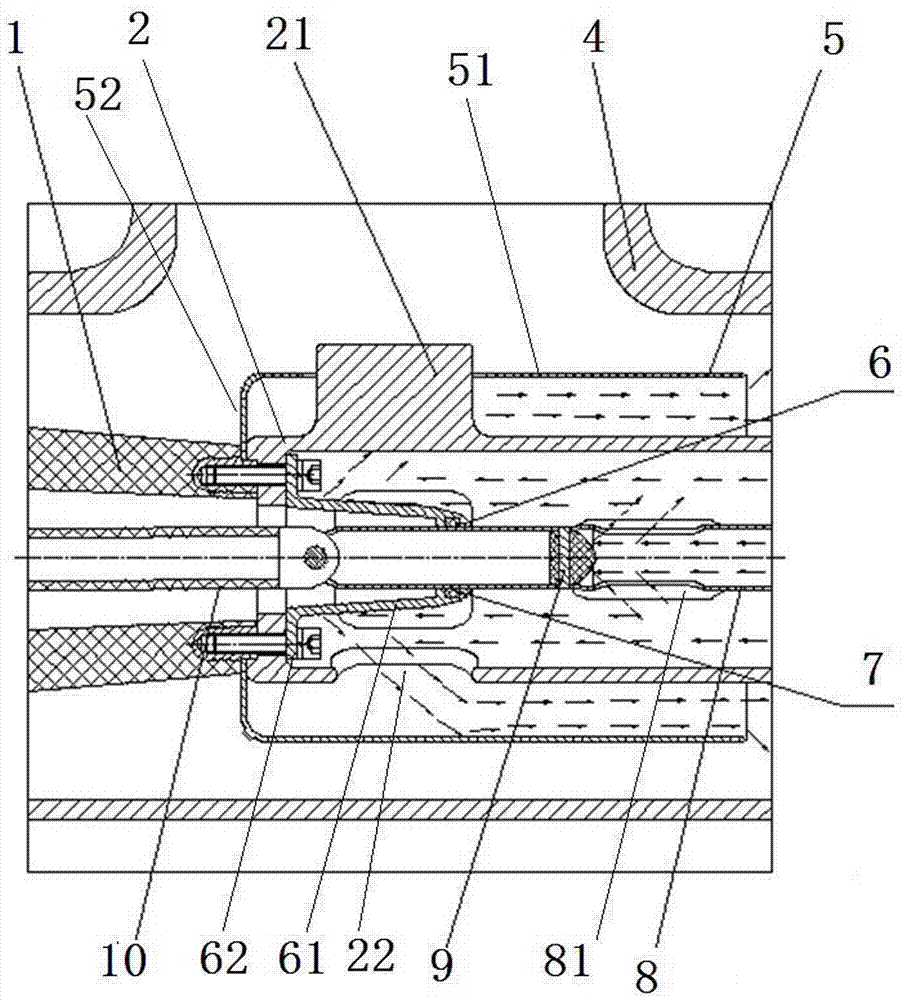

[0017] Embodiments of the tank circuit breaker of the present invention, such as figure 1 As shown, the tank circuit breaker includes a tank body 4 and a gas blocking device at the moving end of the tank circuit breaker. The moving end gas shielding device of tank type circuit breaker includes the moving end insulating support 1, the moving end insulating support 1 is installed with the moving end contact seat 2, and the inner cavity of the moving end contact seat 2 communicates with the cavity of the moving end insulating support 1. The insulating pull rod 10 passes through the cavity of the moving end insulating support 1 and is connected with the moving contact pull rod 8 in the cavity of the moving end contact seat 2 . The moving end contact seat 2 is provided with an inner air shield 6 cover in its inner cavity, and the inner air shield 6 is provided with a passage port for the moving contact pull rod 8 to pass axially, and the inner air shield 6 is provided with a passag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com