An Improved Bone Tunnel Threader Wire Clipping Structure

A threading device and bone tunnel technology, applied in the direction of fixator, internal fixator, internal bone synthesis, etc., can solve the problems of high cost, easy deformation, easy to collapse, etc., and achieve long service life, simple processing, and not easy to deform. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

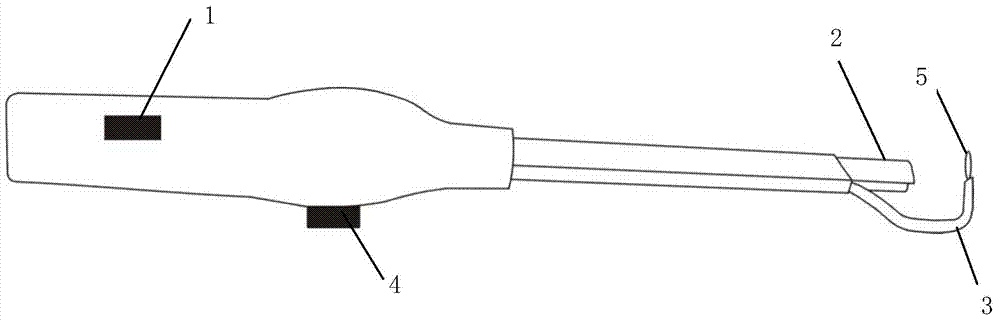

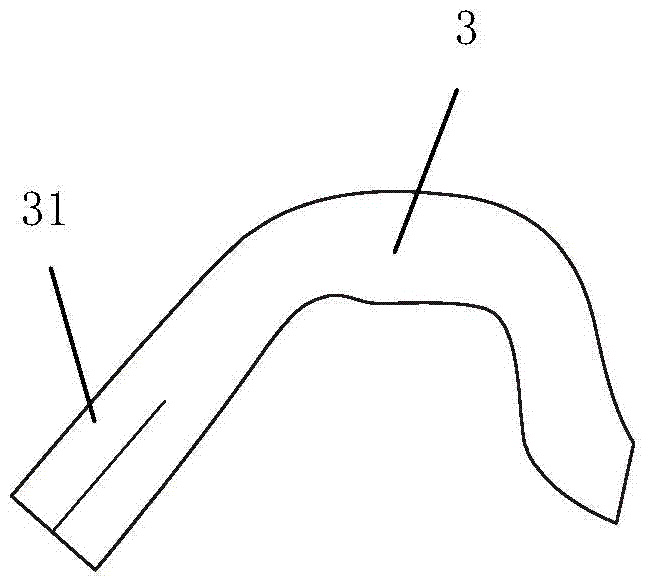

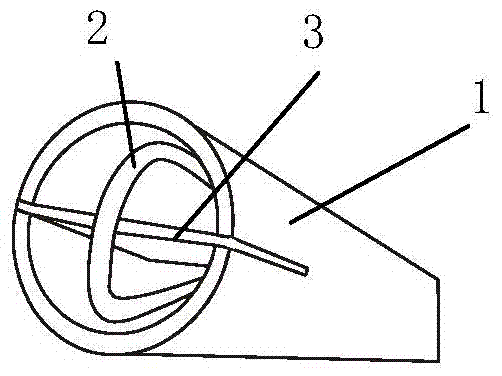

[0027] Such as Figure 3 to Figure 6 As shown, the end 1 of the elbow of the threading pipe in Embodiment 1 is additionally provided with steel wires at both ends of the traveler 2 to facilitate the clamping part of the traveler 2 to clamp the wire. The wall of the part 1 is longitudinally provided with two compartments 11 cut out by laser or molybdenum wire, and the partition 3 is inserted into the two compartments 11 of the elbow end 1 and welded. Of course, the wall at the end of the elbow of the threading pipe can also be provided with only one compartment longitudinally, one side of the partition leans against the inner wall of the elbow end and is welded, and the opposite side is embedded in the compartment at the end of the elbow and welded it is good. The steel wires at both ends of the traveler 2 are respectively arranged on both sides of the partition 3 . It can be seen that the partition plate 3 divides one pipe at the end 1 of the elbow into two pipes, forming a ...

Embodiment 2

[0029] Such as Figure 7 to Figure 11 As shown, the end 1 of the elbow of the threading pipe in the second embodiment is additionally provided with steel wires at both ends of the traveler 2, and the clamping parts that are beneficial to the clamping of the traveler 2 are two branch pipes 4. One branch line pipe 4, half of the pipe wall 41 is removed at the end, the two line branch pipes 4 are arranged back to back longitudinally in the end 1 of the threading pipe elbow, and the steel wires at both ends of the traveler 2 are respectively arranged in the two line branch pipes 4 within. It can be seen that the two back-to-back distribution pipes 4 divide one pipe at the end of the elbow 1 into two pipes, forming a clamping structure.

Embodiment 3

[0031] Such as Figure 12 to Figure 13 As shown, the end 1 of the elbow of the threading pipe in Embodiment 3 is additionally provided with steel wires at both ends of the traveler 2 to facilitate the clamping part of the traveler 2, which consists of a partition 3 and two branch lines Composed of tube 4, the wall of the elbow end 1 of the threading pipe is longitudinally provided with two compartments 11 cut out by laser or molybdenum wire, and the partition 3 is embedded in the two compartments 11 of the elbow end 1 and welded. Of course, the wall at the end of the elbow of the threading pipe can also be provided with only one compartment longitudinally, one side of the partition leans against the inner wall of the elbow end and is welded, and the opposite side is embedded in the compartment at the end of the elbow and welded it is good. The two branch pipes 4 have half of the pipe wall 41 removed from their ends. The two branch pipes 4 are respectively arranged longitudina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com