Secondary gas and liquid mixing pump for nanometer-scale tiny bubble water

A technology of gas-liquid mixing pump and bubble water, which is applied in the direction of mixers, mixing methods, dissolution, etc., can solve the problems that single-stage gas-liquid mixing pumps cannot meet the requirements of gas-liquid mixing effects and fail to achieve nano-scale bubbles, and achieve reasonable Effect of mixing and improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

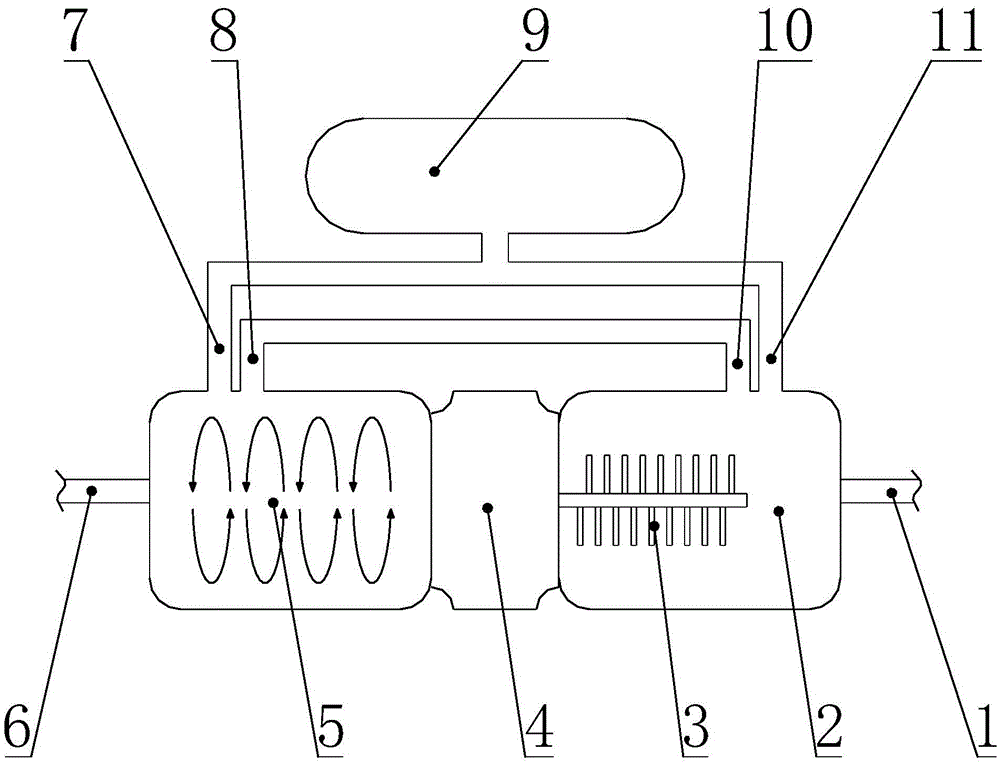

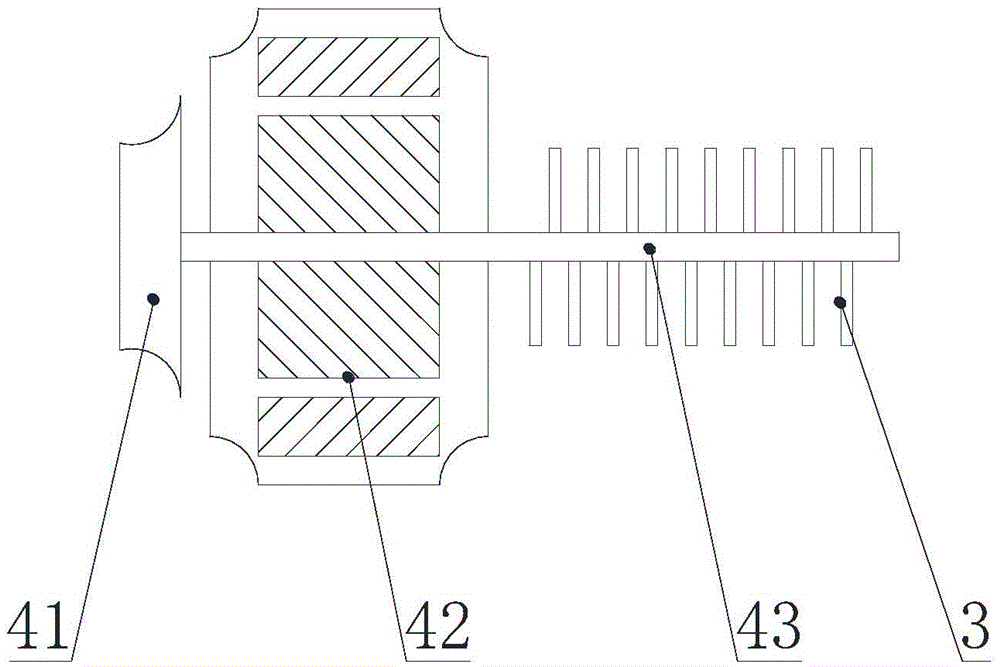

[0032] A two-stage gas-liquid mixing pump for nanoscale micro-bubble water, comprising a stirring mixing chamber 2, a driving device 4, a pneumatic mixing chamber 5 and an air supply device 9, and the stirring mixing chamber 2 and the pneumatic mixing chamber 5 are respectively arranged on the driving device 4, on the side wall of the stirring mixing chamber 2, the first air inlet 11 and the first water outlet 10 are arranged sequentially from top to bottom, and the first water inlet 1 is arranged on the top, and the air pressure mixing chamber 5 The side wall is provided with a second air inlet 7 and a second water inlet 8 sequentially from top to bottom, and the top is provided with a second water outlet 6, and the air supply device 9 is respectively connected to the first air inlet 11 and the second water inlet. The air inlet 7 is connected, and the first water outlet 10 is connected with the second water inlet 8 . The driving device 4 is a motor 42 driven at both ends, the...

Embodiment 2

[0035] Such as Figure 4 As shown, the stirring blades 3 in Embodiment 1 can also be symmetrically arranged or staggeredly arranged, and the purpose is to increase the stirring strength of the gas-liquid mixed water to generate a uniform gas-liquid mixed liquid, and at the same time provide a good balance for the mixed gas-liquid mixture. The liquid provides the power to move downwards, prompting the gas-liquid mixture to flow out through the first water outlet 10 .

Embodiment 3

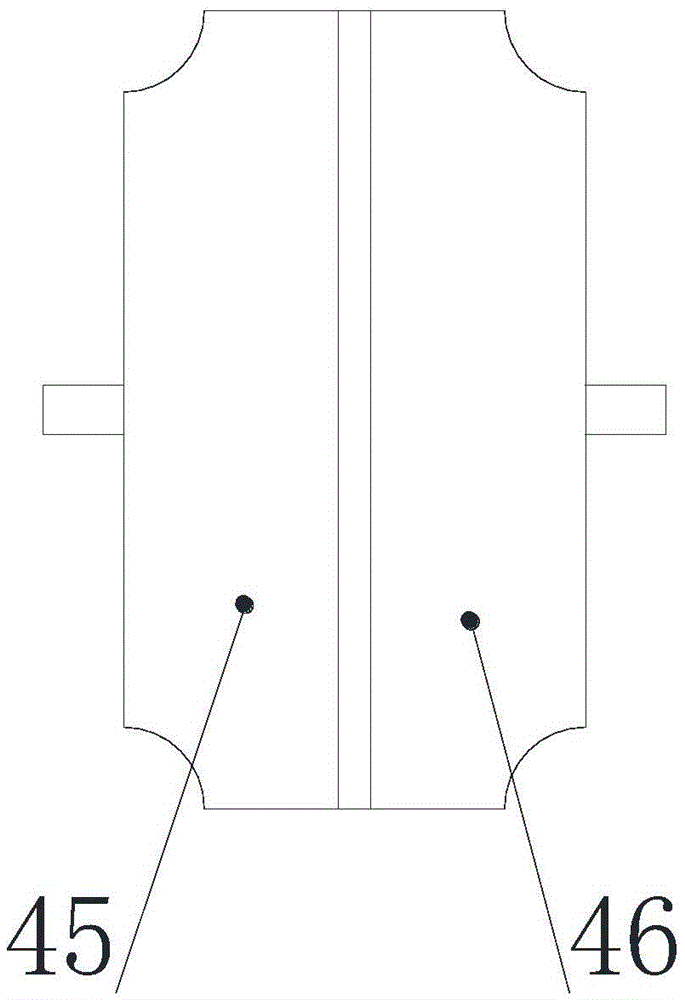

[0037] The driving device 4 in Embodiment 1 can also be a single motor 42 drive system, and the single motor 42 drive system is made up of two first motors 45 and the second motor 46 that are arranged oppositely, and the motor 42 adopts a stepping motor or a servo The motor can control the rotating speed in the stirring mixing chamber 2 and the air pressure mixing chamber 5 respectively, adjust the rotating speed of the stirring blade 3 and the turbine 41 in the stirring mixing chamber 2 and the air pressure mixing chamber 5 according to different requirements, so that the stirring mixing chamber 2 and the air pressure mixing chamber The cavity 5 can form the best speed ratio, improve the quality of gas-liquid mixing, and reduce the energy consumption of the equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com