Special mold replacement apparatus of cold core box core ejecting machine

A technology of mold replacement and core shooting machine, which is applied to molding machines, manufacturing tools, casting and molding equipment, etc. The effect of labor intensity, fast replacement and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

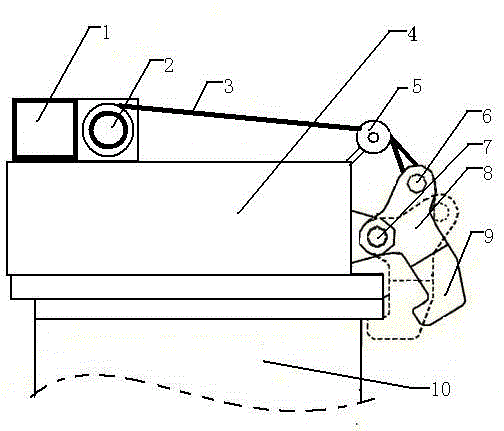

[0014] This embodiment provides a special mold replacement device for cold box core shooter, which is characterized in that: the special mold replacement device for cold box core shooter includes a motor (1), a mandrel (2), a hinge (3 ), shot head (4), fixed transmission wheel (5), hinged shaft (6), rotating shaft (7), locking block (8), hook head (9), mold (10);

[0015] Among them: one end of the locking block (8) of the device is connected to the base on one side of the shooting head (4) of the core shooting machine through the rotating shaft (7), and the other end of the locking block (8) is provided with a hinged shaft (6), The hinge (3) passes through the hinge shaft (6), and is connected to the work cylinder (2) controlled by the motor (1) by means of the fixed transmission wheel (5), and the hook head (9) is welded on the lower side of the locking block (8) , the convenient position under the injection head (4) is the position where the mold (10) needs to be replaced. ...

Embodiment 2

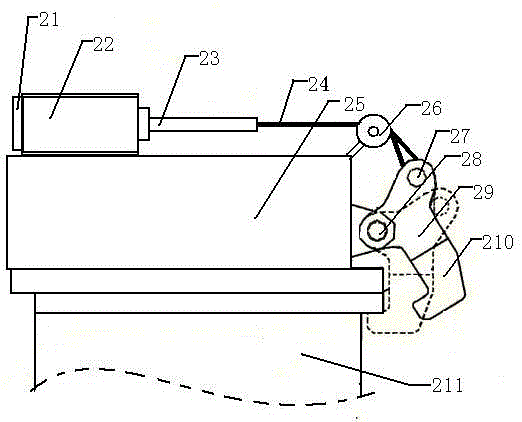

[0019] This embodiment provides a special mold replacement device for cold box core shooter, which is characterized in that: the special mold replacement device for cold box core shooter includes an oil cylinder piston (21), an oil cylinder (22), a connecting rod ( 23), hinge (24), injection head (25), fixed transmission wheel (26), hinged shaft (27), rotating shaft (28), locking block (29), hook head (210), mold (211) ;

[0020] Among them: one end of the locking block (29) of the device is connected to the base on one side of the shooting head (25) of the core shooting machine through the rotating shaft (28), and the other end of the locking block (29) is provided with a hinged shaft (27), The hinge (24) passes through the hinge shaft (27), and is connected to the connecting rod (23) connected to the cylinder piston (21) of the oil cylinder (22) by means of the fixed transmission wheel (26), and the lower side of the locking block (29) is welded There is a hook head (210), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com