Mechanism for enhanced, bi-directional fine adjustment of cutting insert cartridges in machine tools

A technology for cutting inserts and machining tools, used in cutting inserts, tools for lathes, accessories for tool holders, etc., which can solve problems such as loss of productivity and operational efficiency, loss of time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

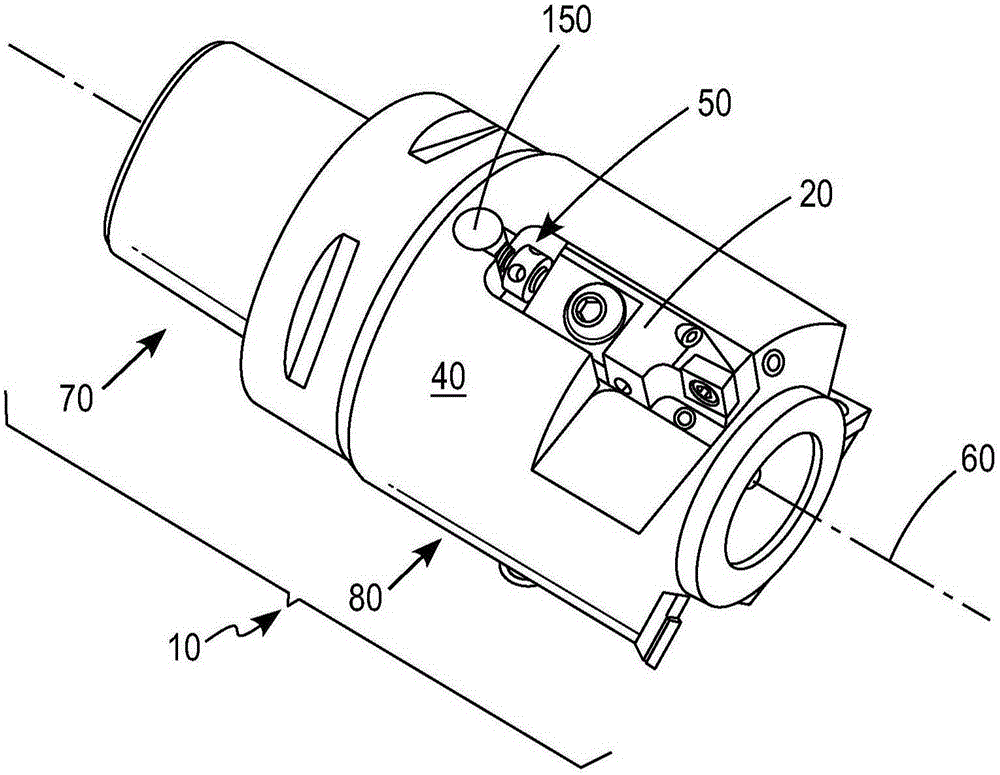

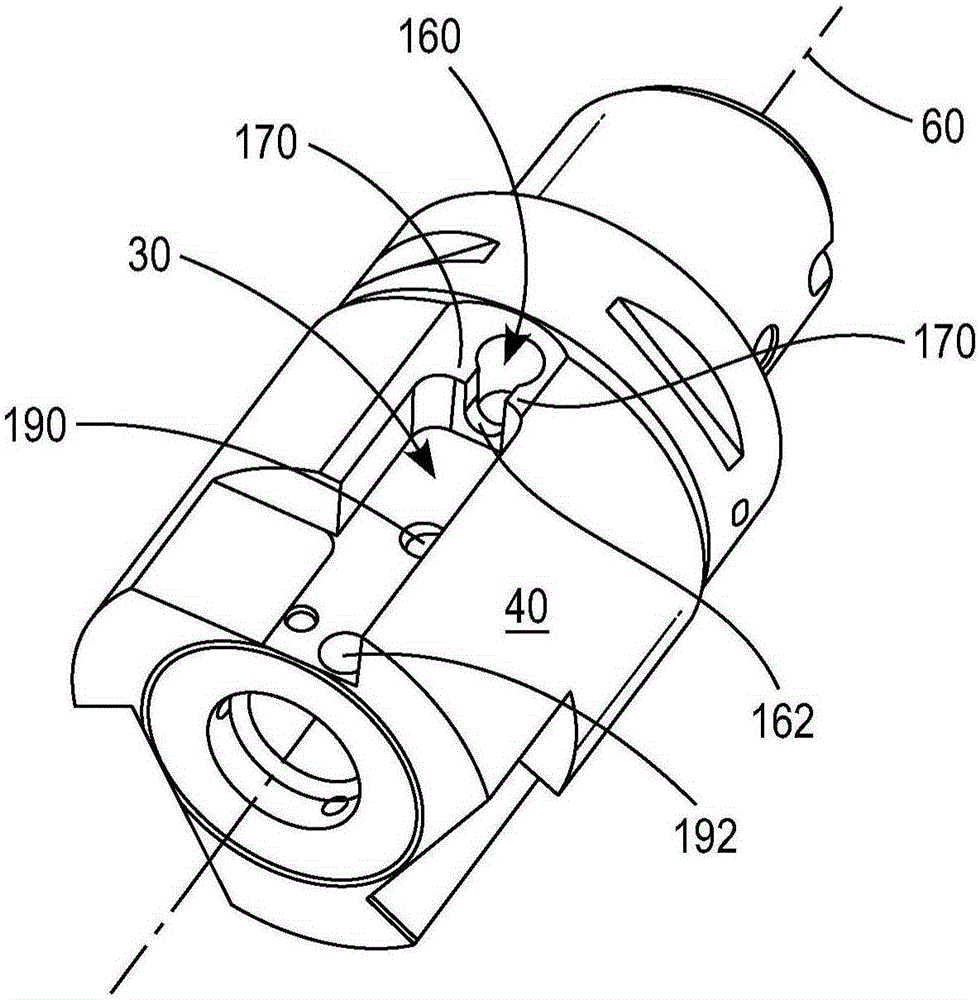

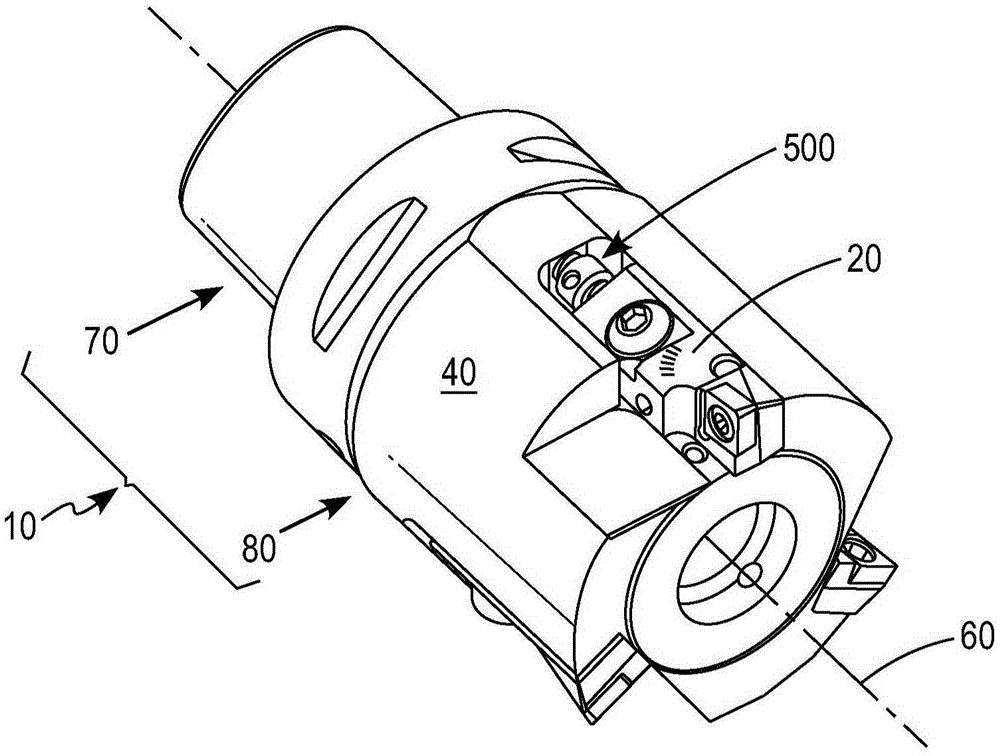

[0022] figure 1 is a perspective view of an exemplary embodiment of a chip removal machining tool with a cutting insert cartridge and a first exemplary embodiment of an axial adjustment system including a differential screw, and figure 2 is a perspective view of another exemplary embodiment of a chip removal machining tool with a cutting insert cartridge and a second exemplary embodiment of an axial adjustment system including a differential screw. Exemplary chip removal machining tools 10 each include a cutting insert cartridge 20 mounted in a slot 30 (or other receiving area) in a surface of a tool body 40 . Axial adjustment system ( figure 1 The first exemplary axial adjustment system 50 in; figure 2 The second exemplary axial adjustment system 500 in ) axially translates the cutting insert cartridge 20 in the slot relative to the longitudinal axis 60 of the tool body 40 . figure 1 with figure 2 Other features of the cutter body shown in include an attachment end por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com