A cylindrical antenna helical laser pattern device and method thereof

A laser and antenna technology, applied in the field of cylindrical antenna spiral laser pattern technology, to achieve the effect of simple and easy operation of the fixture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

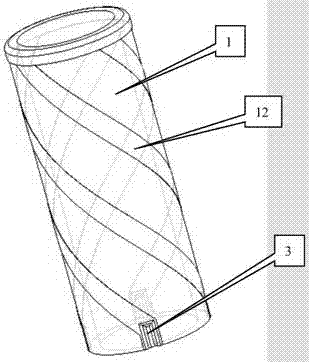

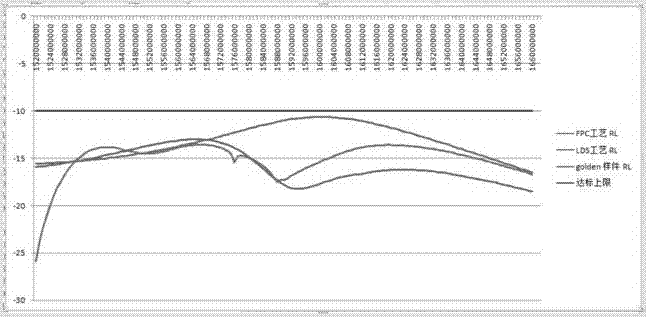

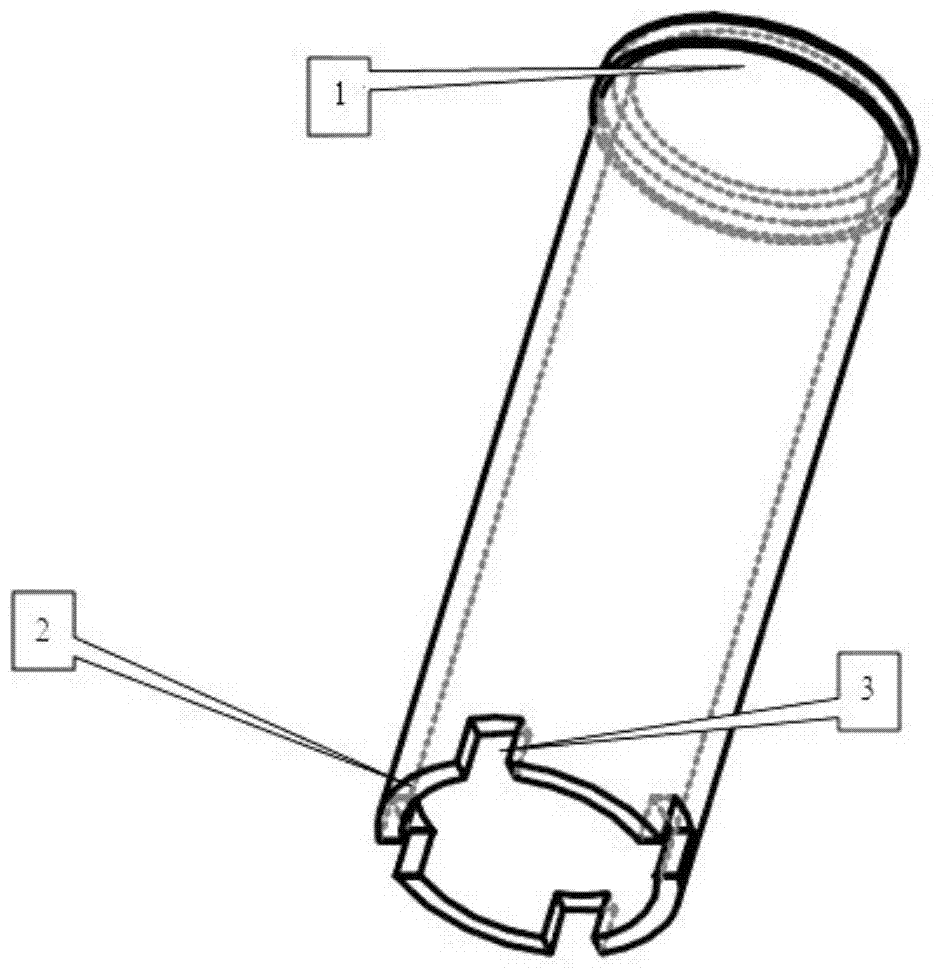

[0057] like Figure 1~3 As shown, the raw material will be fixed on the profiling jig. The profiling design makes the jig completely match the raw material and completely fix the raw material. The raw material directly depends on or is synchronized with the rotation of the profiling jig in the longitudinal rotation. The fixed raw material buckle design is that the raw material is firmly fixed on the profiling jig to prevent the raw material from moving or detaching from the profiling jig during the rotation movement , to ensure the normal operation of the work. Fix the profiling jig on the large chassis of the motor jig by connecting the fixing block to ensure that the profiling jig is connected to the private server motor and rotates concentrically. Before normal work, we use the convex part of the horizontal cylindrical upper surface as the plane point of the laser focal length to make and design the corresponding laser engraving program, including the graphic size of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com