ship cargo transport compartment structure

A technology for cargo transportation and ships, which is applied in the field of ship cargo transportation cabin structure and its unloading, can solve problems such as slow speed and inability to classify cargo, and achieve the effect of reducing liquidity and improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

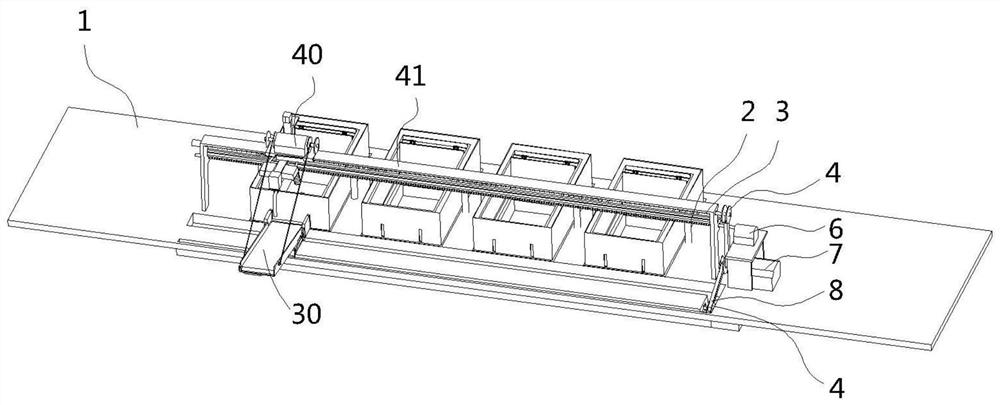

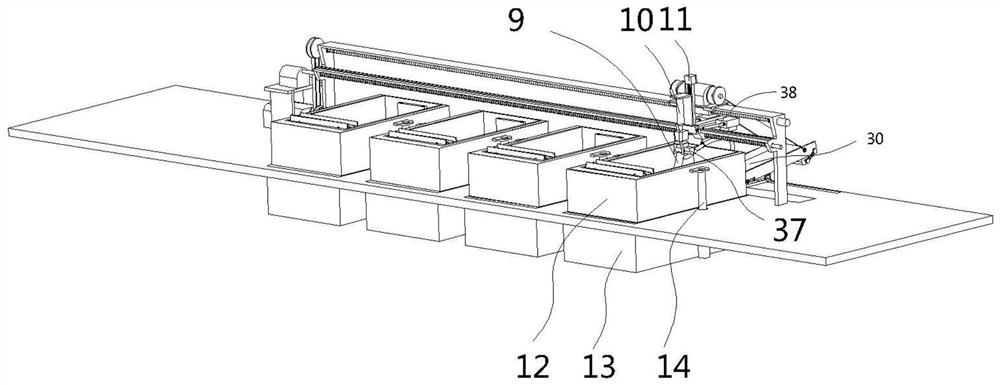

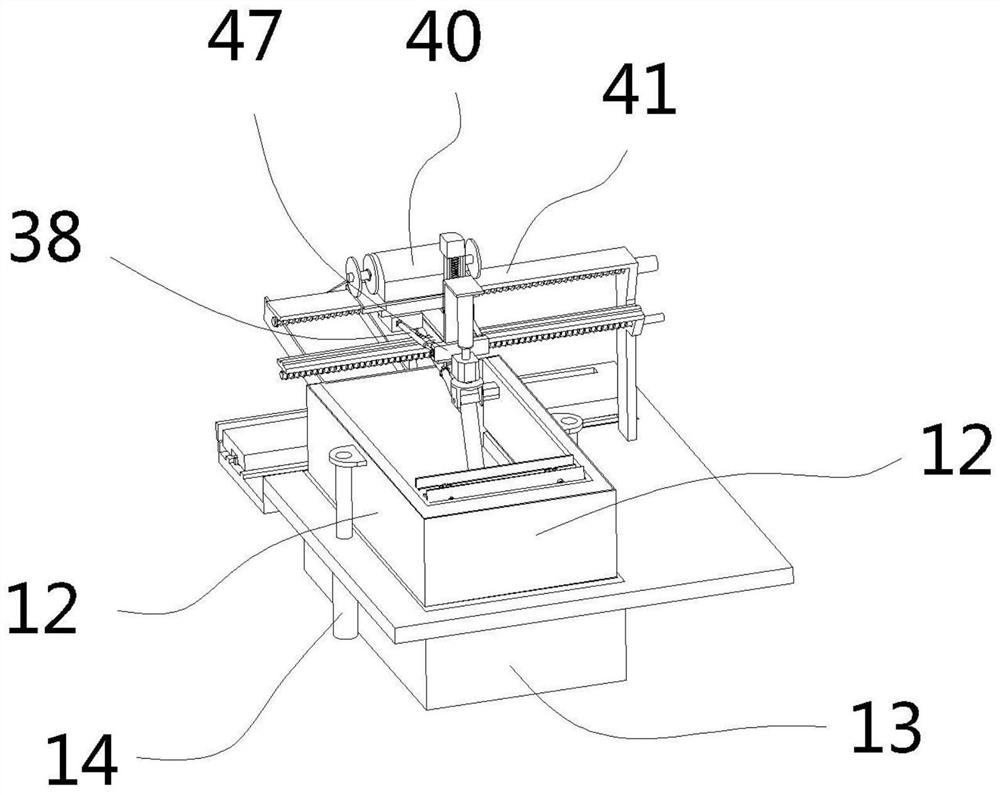

[0027] As shown in the figure, the ship cargo transport compartment structure includes a ship deck 1, and bottom bins 13 are evenly distributed under the ship deck 1, and an upper cargo bin 12 controlled by a hydraulic column 14 is installed in the bottom bin 13. , when there are more than two kinds of goods, the upper warehouse 12 is raised by the hydraulic column 14, and after the bottom warehouse 13 is loaded, the folding plate 15 is returned to the position by lowering the wire rope 2 to seal the bottom of the upper warehouse 12, which can be carried out The loading of another kind of cargo; if it is only one kind of cargo, then the folding plate 15 is directly folded to form an integrated cabin.

[0028] A track frame 41 is installed on the ship deck 1, an upper threaded rod 3 and a lower threaded rod 2 are installed on the track frame 41, and a front threaded rod 36 is also installed on the ship deck 1, wherein: the upper threaded rod 3 and the front threaded rod 36 Pull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com