Large-volume lining model pouring device for tunnel model test and method of large-volume lining model pouring device

A tunnel model and large-volume technology, which is applied in the field of large-volume lining model pouring devices, can solve the problems of difficult control of geometric dimensions and difficult demoulding of linings, and achieve the effect of preventing the bottom from being exposed and facilitating demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

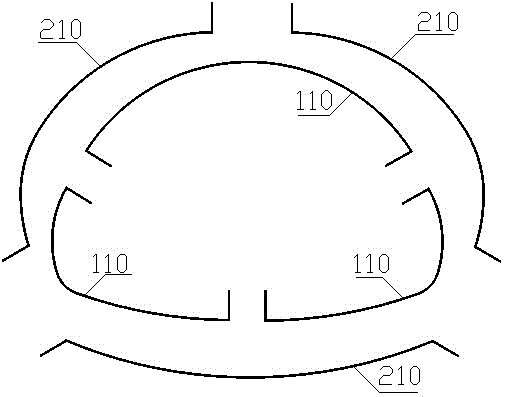

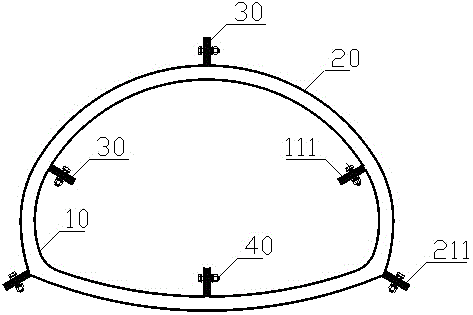

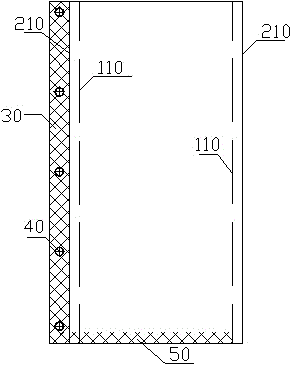

[0026] like Figure 1~4 As shown, a large-volume lining model pouring device for tunnel model tests includes an inner formwork 10 and an outer formwork 20 sleeved on the outside of the inner formwork. The inner formwork 10 consists of three or more inner formwork arc plates 110, the outer formwork 20 is formed by splicing three or more outer mold arc plates 210, and there is a Stop slurry strip 30.

[0027] Both ends of the inner mold arc plate 110 have inner mold fixing plates 111 extending inwardly, and the adjacent inner mold fixing plates 111 of the adjacent inner mold arc plates 110 are fixedly connected by bolts 40, and the slurry stop strip 30 is fixed on the adjacent inner mold fixing plate 111. Between the mold fixing plates 111. In order to facilitate demoulding in the later stage, a Vaseline layer is applied on the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com