Steel concrete integrated building and construction method thereof

A technology of concrete and steel, which is applied in the direction of building structure, construction, and building material processing, etc., and can solve problems such as non-relocation, excessive noise of engineering waste, and long construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

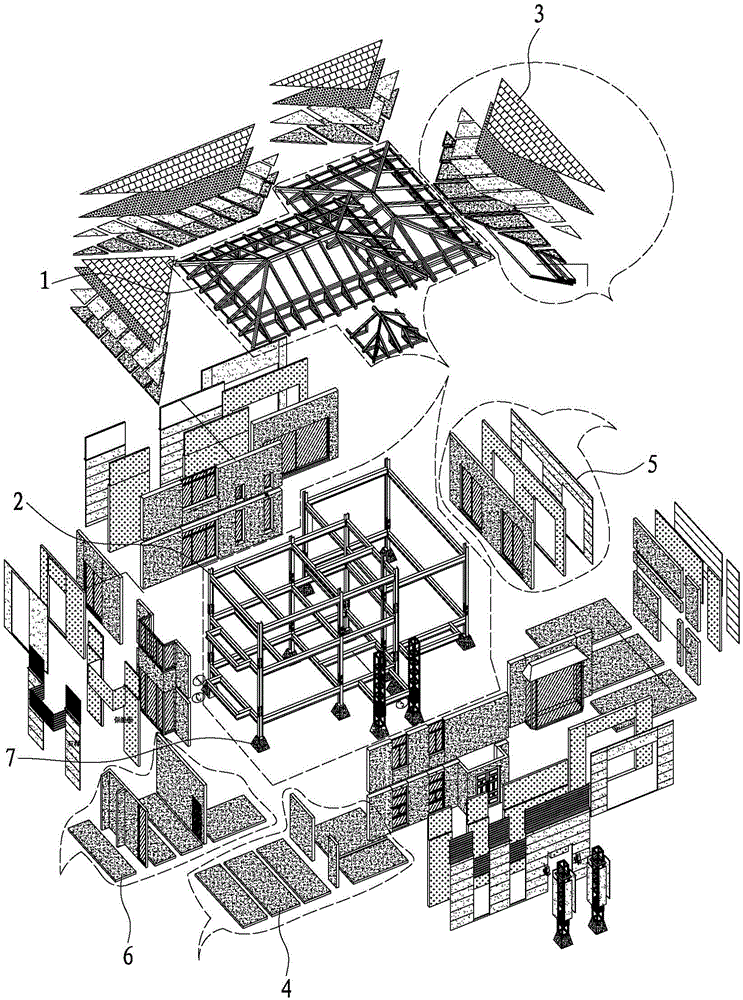

[0032] Such as figure 1 As shown, the present invention is a steel concrete integrated building, which includes a roof steel beam body 1, a steel beam column body 2, a roof panel 3, a floor panel 4, an outer wall body 5, an inner wall body 6, and a basic structure 7.

[0033] The roof steel beam body 1 is installed on the top of the steel beam column main body 2, the lower end of the steel beam column main body 2 is fixed on the foundation structure 7, the roof panel 3 is covered on the roof steel beam body 1, and the floor panel 4 is fixed and installed in the horizontal direction on the Inside the steel beam column main body 2 , the outer wall body 5 is installed outside the steel beam column main body 2 , and the inner wall body 6 is installed inside the steel beam column main body 2 .

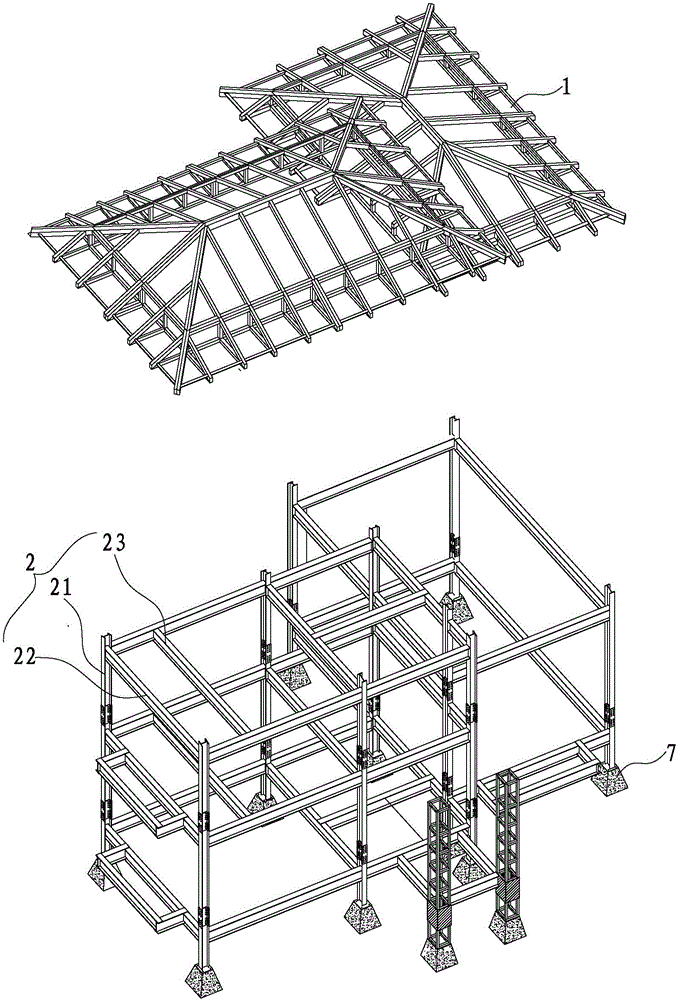

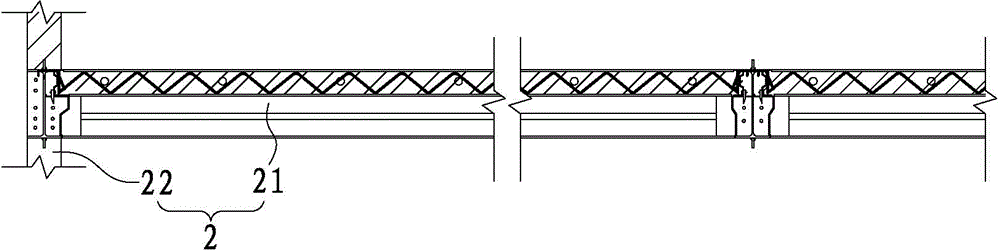

[0034] Such as figure 2 As shown, the steel beam column main body 2 includes a plurality of upright columns 21 , a plurality of cross beams 22 and reinforcing beams 23 . The two ends of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com