Submersible Diaphragm Pump Composite Coiled Tubing Oil Production System

A composite material and oil production system technology, applied in the field of composite material coiled tubing oil production system of submersible diaphragm pump, can solve the problems of rod pumping difficulty, mismatch, broken rod, etc., save operation time, reduce high accident rate, The effect of reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

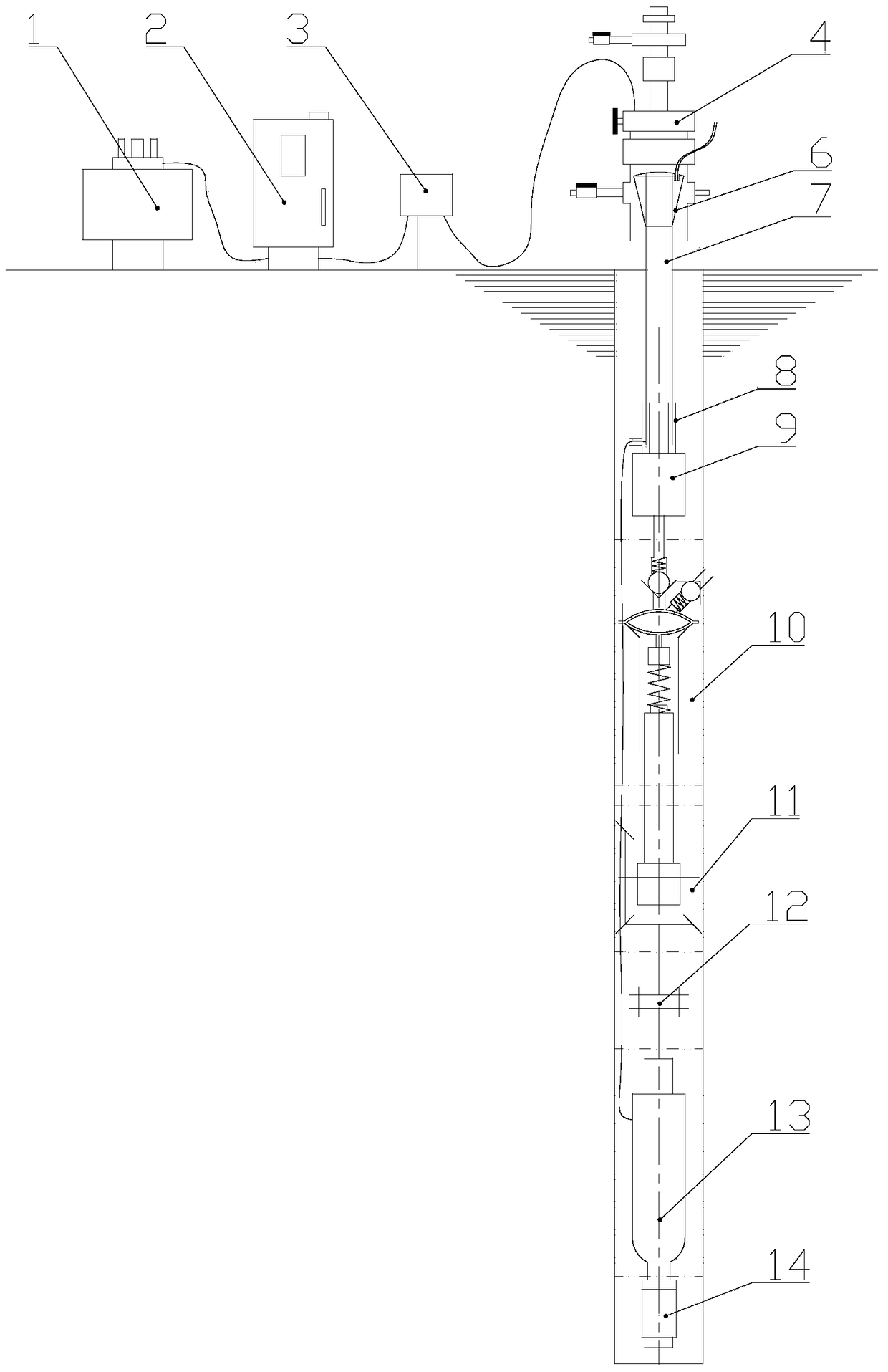

[0046] Such as figure 1 As shown, the composite material coiled tubing oil production system of the submersible diaphragm pump of the present invention comprises a continuous composite material coiled tube 7, and one end (top) of the composite material coiled tube 7 is crimped and connected with a suspension fitting 6, so that the composite material coiled tube This end of 7 is fixed at the wellhead 4 on the surface; the other end (bottom) of the composite material coiled tubing 7 is buckled and connected to a downhole fitting 8, and is connected to the downhole submersible diaphragm pump 10 through the transition joint 9, and the downhole submersible diaphragm pump 10 is decelerated The device 11 and the coupling 12 are connected to the downhole submersible motor 13; the downhole sensor 14 is arranged in the downhole; the downhole sensor 14 is used to measure the temperature and pressure in the downhole;

[0047] The transition joint 9 can be a hydraulic anchor with functions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com