Plate heat exchanger

A technology of plate heat exchanger and heat exchange plate, which is applied in the fields of refrigeration, industrial refrigeration, air conditioning, and heating, and can solve the problems of manufacturing large-diameter holes and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

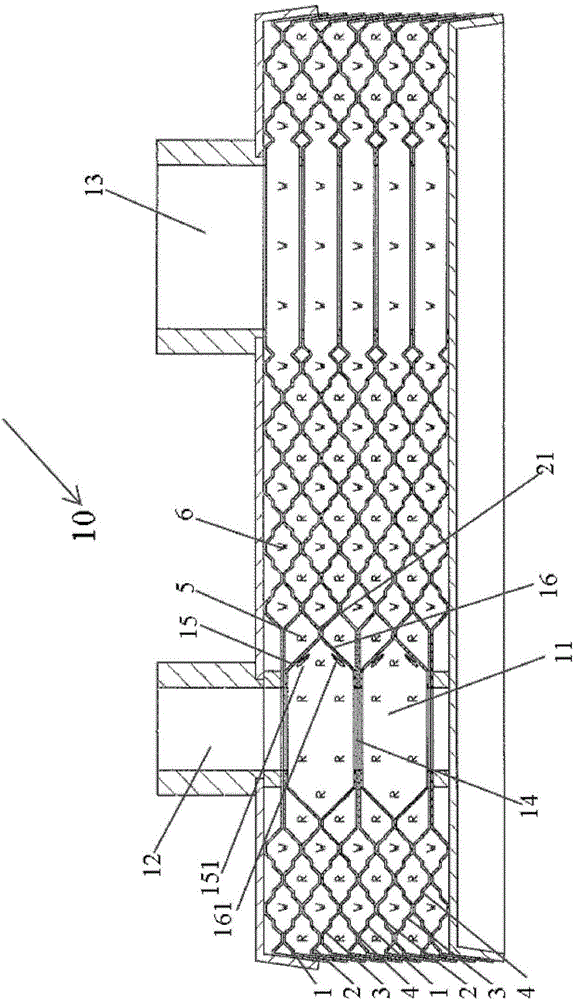

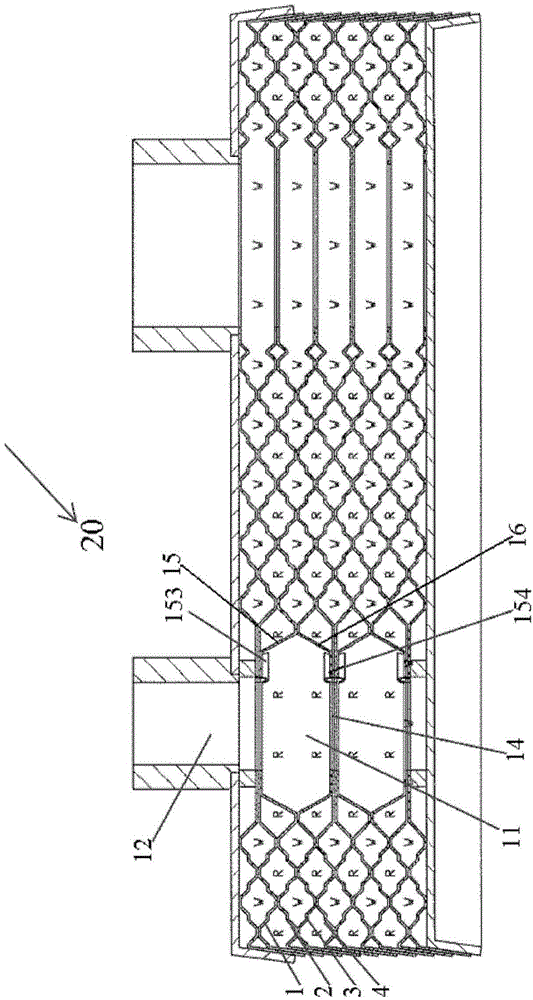

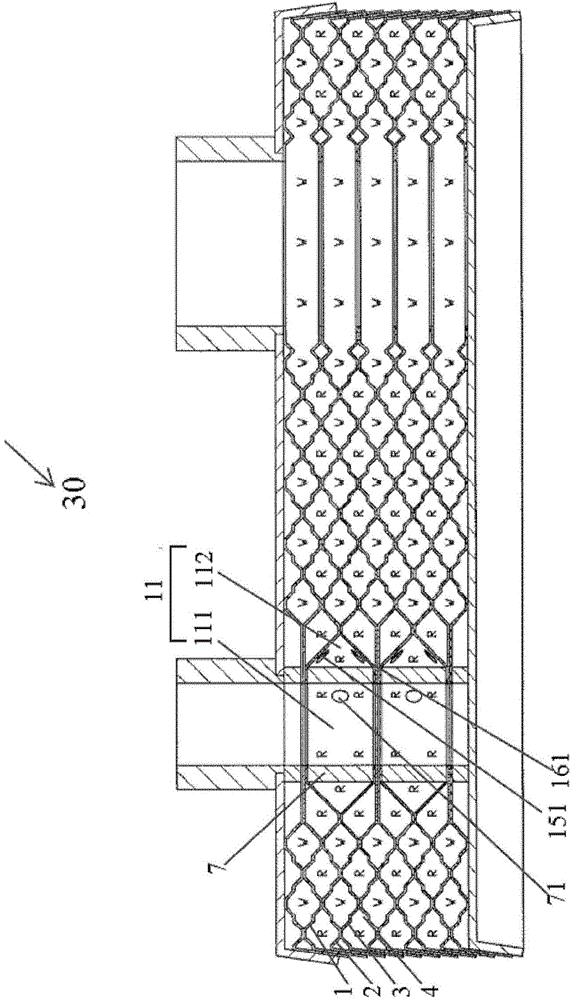

[0033] Through the following examples, combined with the attached Figure 1-6 , the technical solution of the present invention will be further specifically described. In the specification, the same or similar reference numerals designate the same or similar components. The following description of the embodiments of the present invention with reference to the accompanying drawings is intended to explain the general inventive concept of the present invention, but should not be construed as a limitation of the present invention.

[0034] The main idea of the invention is to combine two adjacent fluid channels for the same fluid into one open compartment and to make two holes in the inner wall of said compartment.

[0035] Fluid from the inlet pipes enters the compartment, the flow is split, and passes through the holes of the compartment into each of the respective fluid channels between the heat exchange plates.

[0036] Specifically, such as Figure 1-6 As shown, in some...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com