Three-ball-pin needle bearing outer diameter detecting device

A technology for needle roller bearings and detection devices, which is applied in the direction of measuring devices and instruments, and can solve problems such as the out-of-tolerance of the outer ring of the three-ball needle roller bearing, the high requirements for detection accuracy, and the impact on the use of parts. , to achieve the effect of not easy to wear, easy to observe, and easy to collect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

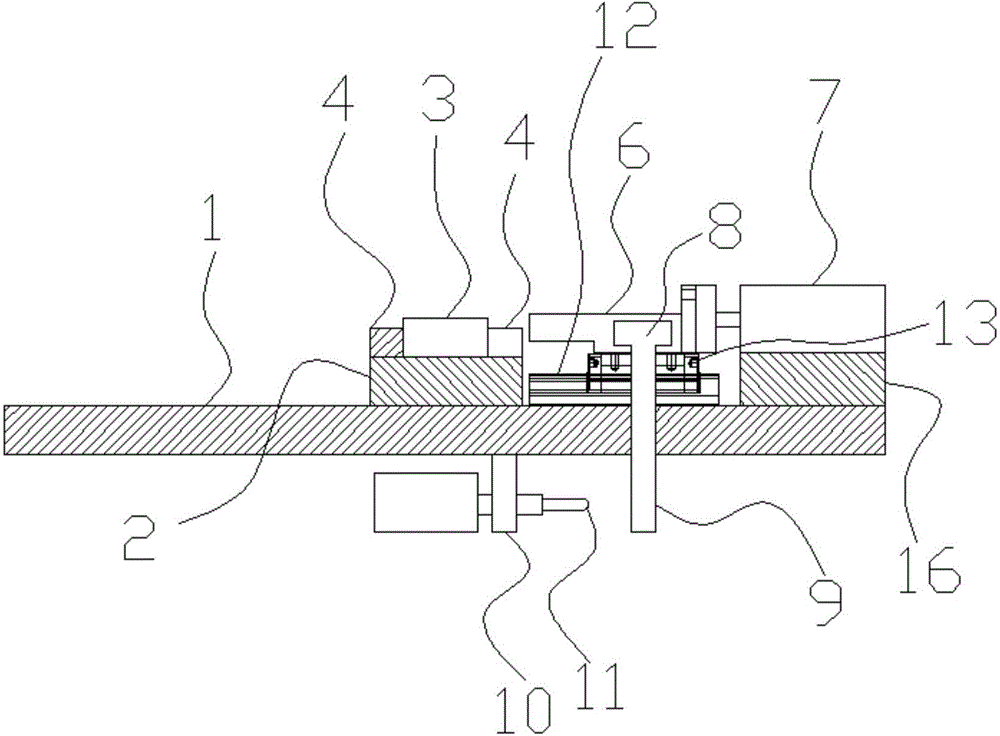

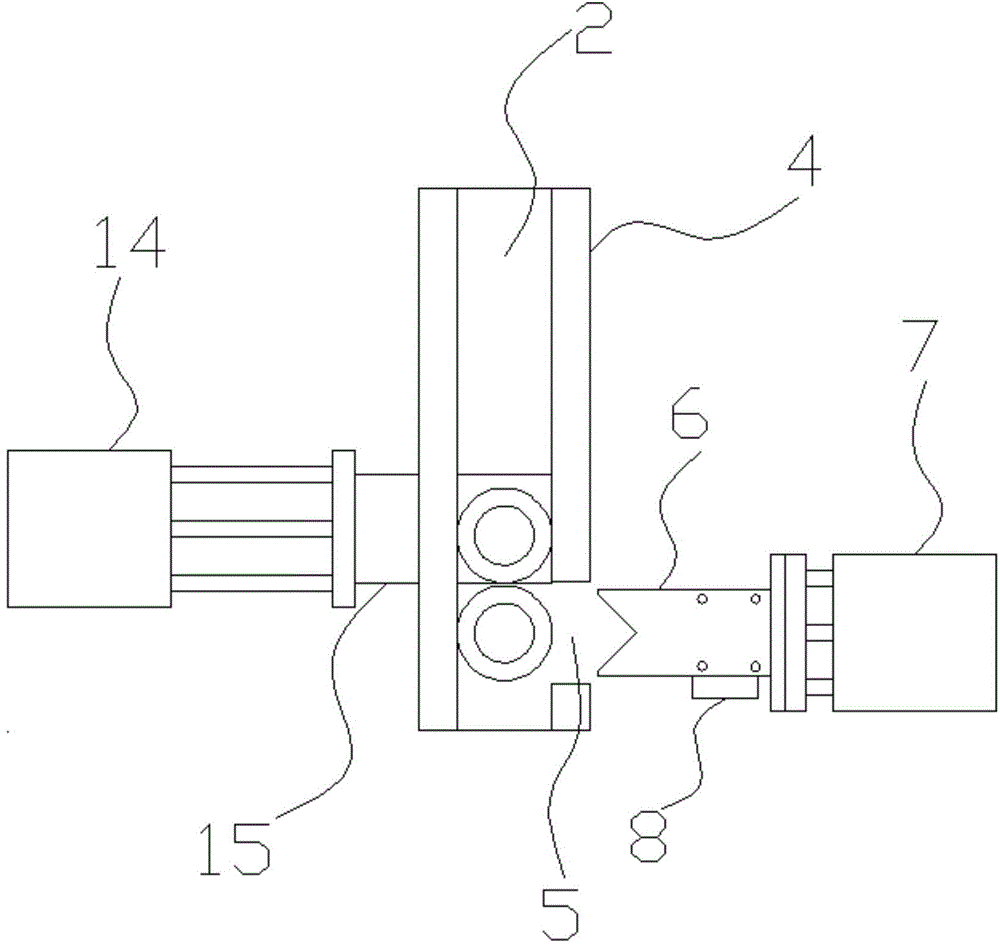

[0021] Embodiment 1: as figure 1 , figure 2 In the shown embodiment, a device for detecting the outer diameter of a three-ball needle roller bearing includes a base plate seat 1, a feeding cylinder, a slide pad 2, and a positioning part. The feeding cylinder is provided with a feeding push plate 3. The skateboard spacer is fixed on the upper surface of the floor seat, and two white steel bars 4 are arranged on the skateboard spacer, and a bearing sliding groove is formed between the two white steel bars on the top of the skateboard spacer , a white steel retaining bar is provided with positioning and extends into the slot hole 5, and the positioning part includes a moving positioning block 6, a positioning cylinder 7 connected with the moving positioning block, and one end of the moving positioning block is provided with a V-shaped The positioning groove, the V-shaped positioning groove extends into the slot hole towards the positioning, the contact measurement block is prov...

Embodiment 2

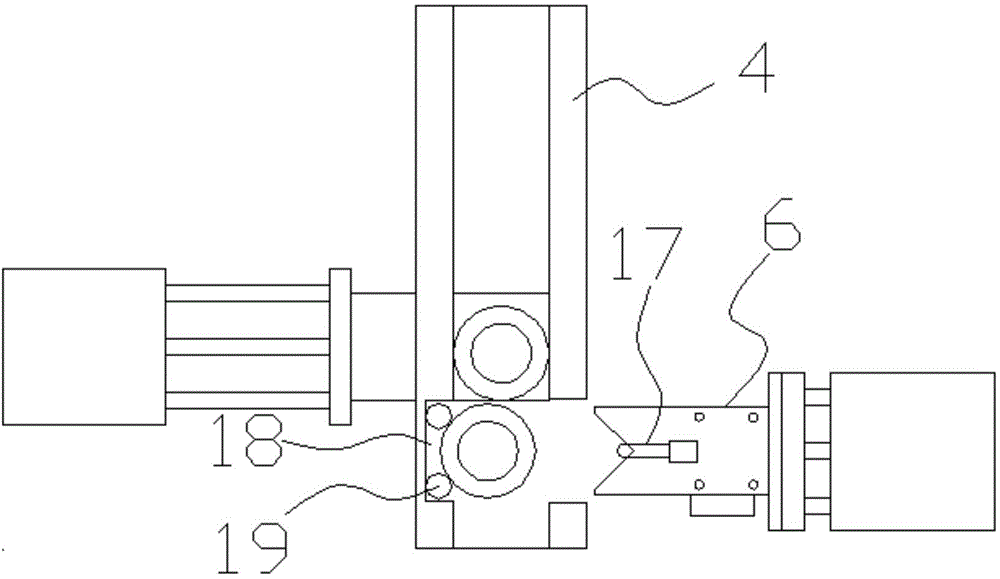

[0027] Embodiment 2: the basic structure and implementation mode of this embodiment are the same as embodiment 1, and its difference is, as image 3 As shown, the moving positioning block is provided with a roundness detection probe 17, the roundness detection probe is in the V-shaped positioning groove, and the roundness detection probe extends into the slot towards the positioning, The roundness detection probe is a distance sensor or a pressure sensor.

[0028] After the bearing positioning is completed, before, after or even at the same time as the outer diameter detection, the roundness detection probe can also be used to detect another point on the outer ring of the three-ball needle roller bearing. When positioning the bearing, the V-shaped positioning groove and The bearing outer ring has two contact lines. When the final test result is within the qualified value range, at least three dimensions on the outer ring of the bearing are qualified, one is the diameter of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com